Choosing Lubricants for High-Temperature Operations

Forging, of course, involves high-temperature operating conditions, and as a result forging operators require lubricants, including greases, that are specifically designed to ensure consistent performance and longevity in such conditions. Choosing the right grease can be essential to helping protect equipment and ensuring a trouble-free operation.

However, in selecting a grease that will help to maximize equipment protection and increase productivity, it is vital not only to consider the quality and performance of a product, but also the requirements and challenges of the specific application.

Operations that function at extreme temperatures and under intense pressure pose a number of lubrication challenges that can only be met by technology that is specifically designed to meet such requirements. Factors such as base oil type, viscosity, thickener type, stability of the composition and operating temperature must all be considered in order to ensure that the most appropriate grease is selected.

Grease formulation — It is important for maintenance professionals to understand how greases are formulated in order to ensure that they select greases that will deliver the

performance factors required to protect the particular equipment over the long term. A simple way to understand grease is to think of it as a sponge soaked with lubricating oil.

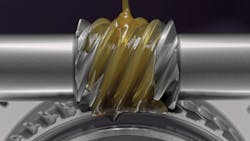

Upon application of external stresses, such as heavy loads or high temperatures, the thickener (i.e., the sponge) releases the oil to lubricate the mechanical parts. When the stress is removed, the thickener re-absorbs a portion of that released oil for later use.

Typically, greases are applied to mechanisms in which a lubricant cannot stay in position, or re-lubrication is infrequent, difficult, or simply not economical. A few examples of this include driveshaft couplings, universal joints, and fan shaft bearings.Selecting a grease for high-temperature operations — In extreme temperature applications, there is a risk that greases will perform poorly due to degradation resulting from thickener and base-oil oxidation, or due to the loss of base oil from grease bleed and evaporation. One of the driving factors that can limit the ability of greases to provide lubrication at higher temperatures is proper viscosity and oxidative resistance. Oxidation is a chemical reaction that occurs between oxygen and the in-service lubricant, and is accelerated in high temperatures.

A grease’s oxidation rate generally doubles with every 15°C rise in temperature above 60°C. This rule-of-thumb will vary according to the type of thickener used in the grease, and for soap thickeners the amount of metal contained in the structure (lithium, calcium, aluminum, etc.) is an influential factor.

Typically, greases with synthetic base oils can provide a wider operating temperature range than conventional, mineral-based greases. For example, the Mobil SHC Polyrex™ Series is a range of high-performance, synthetic bearing greases that uses advanced polyurea thickener technology in order to achieve excellent high-temperature performance up to 170°C.

Even at these extreme temperatures, the polyurea thickener technology resists oxidation and loss of structural stability allowing re-lubrication intervals to be extended while maintaining equipment protection. This carefully balanced combination of thickener, base oils, and additives results in a grease formulation that has excellent load-carrying capabilities and rust protection.

Boosting productivity with synthetics — One manufacturer that benefitted by the use of advanced greases in a high-temperature environment is an aluminum manufacturing and processing plant in Germany. To protect wheel bearings, the plant had been using a grease with a base-oil viscosity of 100cSt, and had been experiencing routine bearing failures and significant mechanical wear and tear due to lubricant degradation, as a result of excessive heat. In addition, the plant also was incurring high lubricant costs.

A team of ExxonMobil technical experts were asked by the plant’s maintenance team to develop a comprehensive analysis of the plant’s operations and equipment-maintenance practices, in order to address these issues. Following the audit, the ExxonMobil technicians made specific recommendations to convert the lubricant protecting the wheel bearings to Mobil SHC Polyrex 462, in addition to implementing a best practice program to help increase re-greasing intervals.

The higher base-oil viscosity offered by Mobil SHC Polyrex 462 provided the machinery with improved levels of protection, resulting in a noticeable reduction in component damage. The introduction of Mobil SHC Polyrex led to an overall improvement in performance and resulted in an annual saving of about $55,000*.

With ongoing developments in machine design and function to increase output, and the high ambient temperatures that are standard in many industries, lubricants that can operate effectively in extreme conditions will enable manufacturers to build a competitive advantage into their operations by reducing downtime and increasing productivity.

Jarmo Vihersalo is ExxonMobil’s industrial marketing advisor, EAME, for. Direct inquiries to ExxonMobil Lubricants Technical Help Desk - [email protected] , or +420-221-456-426. Or, visit www.mobilindustrial.com.

* This “proof of performance” is based on the experience of a single customer. Actual results may vary depending upon the type of equipment in use and its maintenance, operating conditions and environment, and any prior lubricant in use there.