Case Study: Major Automotive Manufacturer Replaces Field-Erected Cooling Towers With Modular Ones

How do you replace aging cooling towers without risking disruption to a plant's continuous high-volume operation? That was the challenge at a major Midwest automotive manufacturing facility. Automobiles began rolling off the production line in the late 90s and the existing cooling towers were due to be replaced.

The cooling tower replacement was part of a plant modernization project that included retooling, new equipment, and advanced manufacturing technologies, expanding capacity to 420,000 vehicles annually to meet strong demand primarily for the company's popular vehicles.

The Challenge

Replacement of the enormous field-erected cooling towers was no small task, and it needed to be completed within the limited period when cooling was not required to avoid causing any downtime of plant operations. The demolition could not begin until December and the site preparation, installation, and commissioning of the new cooling system had to be completed by April.

The automotive company worked with ElitAire, LLC to evaluate the technology alternatives and develop a plan. The first decision to be made was the construction method—whether to replace the existing non-BAC field-erected towers with a similar site-built system or to install a modular system built offsite in BAC’s factory. The second decision was the drive technology for the fans—whether to continue using a gear drive system or shift to direct drive technology.

The customer’s main goal was to control risk, the risk of delays in the installation process that could cause production downtime, and the risk to worker safety, which was of paramount importance. The procurement team was also looking for a solution that was energy efficient and low maintenance to reduce costs and environmental impact.

Modular System Lowers Risk

After an evaluation of the lifecycle costs and weighing the risks of various alternatives, the company selected BAC’s modular Series 3000 Cooling Tower with the direct drive ENDURADRIVE Fan System.

Although the company had previously installed two Series 3000 modules at a different plant location, this project was different in two respects. First, this project was significantly larger in scale. Second, whereas the previous project was a new installation, the current one involved replacement units that utilized the existing concrete cold-water basin. These differences coupled with the time constraints added complexity and risks.

Taking these factors into account, BAC’s Series 3000 Cooling Tower was the ideal solution. The automotive plant was able to replace its existing 6 field-erected towers with 12 modular Series 3000 Cooling Towers while reusing the existing concrete cold-water basin.

A key factor in the company’s decision was the installation time. Remarkably, the mechanical construction firm was able to install the full array of the Series 3000 modules in only four days, compared to the more than 60 days that would have been required to assemble a field-erected system of the same size and capacity.

As noted by Hassan Alhashim, the lead project engineer at ElitAire, “Instead of taking 2 to 3 months to erect site-built towers, the modules were each installed in about 3 hours, and the entire process from demolition to completion was accomplished well within the four-month window.”

Moreover, the company was able to perform visual inspections and factory acceptance testing of the Series 3000 modules prior to their leaving BAC’s factory, rather than relying on the more difficult and time-consuming process of performing these tests on site.

Compressing the schedule and reducing the risks of delays inherent in field construction projects was critically important to the automotive company, but so was reducing safety risks, a central component of their corporate culture. BAC’s modular cooling towers are built offsite in BAC’s factories under strict quality control and EHS standards. The modular towers are shipped to the job site when complete in upper and lower sections with minimal field assembly time. Using factory-built modular cooling towers reduced safety risks for the customer since the plant was not an active construction site for multiple months as it would have been with field-erected towers.

Learn more about BAC’s Environmental Health and Safety (EHS) program by reading the company’s Environmental, Social, and Governance (ESG) Report at www.baltimoreaircoil.com/sustainability.

Direct Drive Lowers Costs and Environmental Impact

In their old equipment, the customer had been using gear drive systems but decided to take advantage of BAC’s direct drive ENDURADRIVE Fan System in the new cooling towers. Direct drive designs remove mechanical losses and thereby save energy compared to gear and belt drive systems, reducing costs and carbon footprint. Direct drive motors employ efficient and reliable permanent-magnet technology and eliminate the expense and environmental impact of oil changes.

Gear drive systems require much more maintenance, including gear oil inspections and regular oil changes.

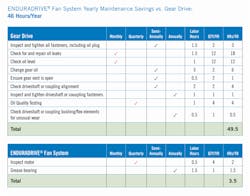

For manufacturing plants that factor OSHA rules for work in confined spaces into purchasing decisions, direct drive fans require significantly less frequent entry for maintenance. This customer conducts their own maintenance in-house and by switching to the ENDURADRIVE Fan System, will realize an average annual operational savings of $95,664 and significantly reduced planned maintenance hours as shown in the Preventative Maintenance Schedules chart below.

Conclusion

The Midwest automotive manufacturer’s modular cooling towers from BAC equipped with the ENDURADRIVE Fan System were installed on time and on budget and have operated reliably while significantly reducing maintenance. Since this installation, the customer has continued to install modular Series 3000 units at other U.S. locations and choose BAC to meet its cooling needs.

Steve Klein, PE MBA is the Global Technical Director – High Growth Verticals at Baltimore Aircoil Company.