Layoffs, Social Distancing May Drive Machine Shops to Automate Finishing Operations

Whether driven by the reduction of in-shop personnel due to layoffs or to maintain social distancing guidelines into the future, many machine shops will likely be re-evaluating ways to eliminate labor-intensive manual operations if they can be automated instead.

At the top of this list are secondary finishing operations that are conducted offline to remove excess material on parts fabrication. Today, much of this work is still performed by hand using oscillating tools, grinders, files, abrasive hand pads, and wire brushes.

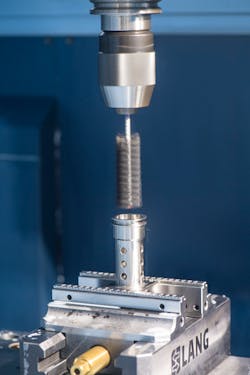

Fortunately, secondary operations such as honing and polishing can be accomplished using a variety of abrasive tools mounted in the CNC machine toolholder and carousel without taking the part offline. The better news is that in addition to reducing in-shop labor requirements, completing surface finishing simultaneously in the same operation as machining also speeds production of high-volume parts.

“When the economy begins to recover in the coming months, machine shops are going to be driven to continue to find a way to increase efficiency and one way is through automating offline processes,” says Tim Urano, Quality Manager at Wolfram Manufacturing, a company that machines metal parts with complex geometries on 4 and 5-axis machines. “So, any time we can incorporate secondary operations right into the machining process, we save time, money, and also reduce our in-house labor requirements.”

According to Urano, Wolfram Manufacturing produces a variety of complex parts with through-holes and so has automated the cross-hole deburring process. Removal of burrs and sharp edges in cross-drilled holes and other difficult-to-access areas such as undercuts, grooves, slots, or internal holes is critical. Failing to remove burrs can cause blockages or create turbulence in the flow of fluids, lubricants, and gases through critical passages.

To do this, the machine shop incorporates Flex-Hones in a variety of sizes in its tool carousels. The Flex-Hone, from Los Angeles-based Brush Research Manufacturing (BRM), is characterized by the small, abrasive globules that are permanently mounted to flexible filaments, the product is a flexible, low-cost tool used for sophisticated surfacing, deburring, and edge-blending. The hones are available in a variety of abrasive types, sizes, and grit selections.

Urano says the hones have been installed for eight years and are used daily, usually several times an hour, on some of the shop’s highest volume parts.

“On a given part, we might deploy two to three different size hones, depending on the number of cross port intersections and different hole sizes,” explains Urano. “It is very easy to put a Flex-Hone in a toolholder, give it a simple toolpath cycle, and let it run.”

“Automating cross-hole deburring eliminates a lot of offline work,” adds Urano. “The parts we make are complex and have a lot of intersecting holes, so relying on a person to repeat that process every single time to the quality level required will always introduce some potential inconsistency there. However, if you just let the CNC machine do its work, it will achieve more consistent results.”

The same tool can also be used to create a high surface finish on the internal bores of a valve assembly actuator that the shop manufactures. As part of a multi-step process, Wolfram Manufacturing uses a coarse grit Flex-Hone to smooth out any irregularities left during drilling and finishes the bore with a fine-grit hone.

In addition to honing, there are a variety of other finishing operations that can be automated using abrasive nylon brushes in a disc, wheel, cup, and end brush designs.

When an application calls for surface finishing, cleaning, polishing, deburring, edge blending, or removal of paint, rust, or other contamination, these types of tools are the ideal solutions. In some cases, these multi-purpose tools can even eliminate machining operations traditionally performed by chamfer tools and face mills.

For JR Precision & Welding, a machine shop in Houston, Texas, the issue of removing large burrs from machined holes in an extremely hard 4140 steel alloy part used as a muzzle brake for firearms was proving a challenge. To remove these burrs, the company decided to automate the process using a 3” diameter abrasive nylon wheel brush with silicon carbide filaments from Brush Research.

Muzzle brakes are devices connected to the barrel of a rifle or pistol to help control recoil and the rising of the barrel that normally occurs after firing. The parts use slots, vents, holes, and baffles to redirect a portion of propellant gases to counter recoil and unwanted muzzle rise. Where and how these holes are placed has a tremendous effect on recoil and muzzle movement.

When machining these holes, however, large burrs were forming at the oval-shaped gas ports. The cylinder was made of 4140 steel, which is a 1% chromium-molybdenum steel alloy that is generally hardened and tempered to a tensile strength of 850 to 1,000 Mpa.

According to says James Mawazeb, Director of operations and lead engineer at JR Precision & Welding, the abrasive nylon fit well into the shop’s 5-axis machine magazine holder and existing toolholders.

“In addition to removing the large burrs, the wheel brush also provided a soft edge break to the ports so they were not razor-sharp without affecting the surface finish,” says Mawazeb.

Even miniaturized brushes as small as 0.014” in abrasive nylon, carbon steel, stainless steel, and diamond abrasive filaments can be used with adaptors on CNC equipment. These tools are ideal for deburring internal and external threads. Internal threads often have micro burrs at hole entrances and exits, on thread crests, and on most slot edges. External threads on bolts, screws and spindles have similar issues, particularly at the start of the thread.

Regardless of the type of finishing operation or abrasive tool used, automating secondary processes is one-way machine shops can reduce unnecessary in-shop labor to replace lost personnel and to maintain social distancing into the future.

For more information, contact Brush Research Manufacturing, Brush Research Mfg. Co., Inc., 4642 Floral Drive, Los Angeles, CA 90022; Phone: (323) 261-2193; Fax: (323) 268-6587; email: [email protected] or visit the web site: www.brushresearch.com

About the Author

Jeff Elliot

Jeff Elliott is a Torrance, Calif.-based technical writer. He has researched and written about industrial technologies and issues for the past 15 years.

Brush Research Manufacturing

Brush Research is a privately owned company located in Los Angeles, California. We've been in the business of solving difficult finishing problems with brushing technology since 1958.