Case Study: Scheucher Achieves 100% Inspection on Parquet Flooring With AI Vision

What You'll Learn:

- How AI-powered IDS NXT rio cameras perform real-time, inline inspection of adhesive joints in multilayer parquet flooring

- Why Scheucher chose an edge-based vision system over traditional PC-based or rule-based image processing

- How the system enables 100% inspection accuracy using just 60 good/bad samples to train a neural network

- What makes the IDS NXT rio suitable for industrial environments, including its embedded processing and OPC UA support

- How this implementation reduced energy usage, eliminated PC hardware, and inspected parts in under 90 milliseconds

Scheucher Integrates AI Vision for Multilayer Parquet Quality Control

Parquet flooring creates a warm and inviting atmosphere with its natural grain and color tones that have a lively effect and add character to a room. Next to hardwood floors, parquet is the next best thing as its a bit more durable and offers an optional click system for easy installation.

Scheucher Holzindustrie GmbH from Mettersdorf in Austria is now in its fourth generation of manufacturing high-quality parquet floors and combines tradition with modernity in its production. The company relies on image processing with artificial intelligence (AI) to inspect the glue joints of its multilayer parquet, or more precisely, using IDS NXT, the all-in-one intelligent camera system.

Technical Requirements for Adhesive Bond Inspection

Not all parquet floors are the same. In addition to solid variants, multilayer parquet is particularly popular. Several aspects must be taken into account during its manufacture to obtain a high-quality, durable, and user-friendly product. The choice of wood species, for example, influences the stability and appearance of the parquet. As the name suggests, it consists of several layers—in particular, a core layer and a wear layer. Scheucher uses spruce or pine as backing. A variety of wood species can be chosen for the wear layer.

Inline Inspection Using UV Fluorescence and Edge AI Cameras

A major advantage of "prefinished parquet" is its ease of installation. Many types can be laid as a floating floor, so they don't need to be glued down. With a little manual skill, even inexperienced people can install their own wooden floor. A click system ensures the exact fit of the planks. They are simply clicked directly into each other. This saves time and reduces the workload.

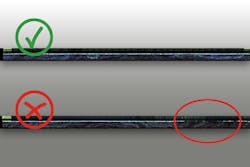

The click system must be milled with high precision so that the panels interlock stably and precisely. Incorrect milling can lead to problems during installation and instability. The same applies to the adhesive bond between the core layer and the wear layer of the parquet. The adhesive must be applied evenly to ensure complete coverage and a uniform bond between the layers. Air inclusions or irregular application quantities can lead to cavities and impair the durability.

"In the profiling for our MULTIflor parquet floors, a special click profile is milled into the planks. During this process, two intelligent IDS NXT cameras are used to check the presence of adhesive in the adhesive joint between the core and the backing layer," explains Dipl.-Ing. Klaus Bauer, Research & Development at Scheucher.

Implementing IDS NXT Rio: System Architecture and Setup

Scheucher illuminates the already glued parquet planks with UV light. The adhesive fluoresces and adhesive residues become visible. Scheucher relies on image processing with artificial intelligence to detect faulty floorboards.

The package includes the required hardware, in the form of an IDS NXT rio industrial camera with a 1.6 MP Sony color sensor, including power and data cable, tripod adapter, and lens, as well as the required software in the form of an IDS lighthouse license. This allows users to concentrate fully on the planned application without having to worry about deep learning, image processing, or camera programming.

Achieving Sub-100 ms Inspection Cycle Times

"In our profiling system, we had not used any image processing, neither rule-based nor intelligent, for the quality control of our bonded joints until now. Nevertheless, it was our goal, even as a layman, to solve this requirement using AI. As we are looking for errors that only occur extremely rarely, our challenge was to find a sufficient number of "bad partial images" to train the neural network," explains Bauer.

"And we succeeded. In the end, we needed around 60 good and bad part samples before the AI had learnt to recognize the threshold between OK and NOT OK."

Results: 100% Inspection Rate Without PC-Based Processing

Faulty panels can be reliably sorted out and reworked. The system prevents planks with defects in the parquet bonding from being delivered to customers.

"This makes us one of the few manufacturers on the market to achieve a 100% inspection in this regard," says Bauer. Especially as it takes less than 90 milliseconds to check a floorboard.

Scalability: Building a Foundation for Future AI Applications

In this example, the inspection of the glued joint could also be solved using classic, rule-based image processing, though with increased programming effort. However, it was important to Scheucher to find an intelligent solution. This means that the company is prepared for further applications, as Klaus Bauer emphasizes: "The task was a good introduction to AI-supported image processing for us. Especially because the learning curve was quick." This paves the way for further applications and future-proof, efficient production.

With the help of intelligent image processing systems, objects can be classified or checked for defects, deviations, and quality problems. This can reduce errors and increase productivity in a wide range of industries and applications.

The AI-based all-in-one vision system from IDS shows that this is not highly complex and reserved purely for experts. Scheucher Parquet and IDS NXT have something in common: Thanks to sophisticated systems, even non-professionals can use it and achieve first-class results, such as the perfect parquet shown here.