Bearing Maintenance Made Easier: 3 Product Innovations You Should Know About

Many plant technicians are familiar with routine bearing maintenance, including installation, removal, and re-greasing of critical machine bearings. These tasks can be time-consuming depending on the type of equipment, bearing location and methods used; in all cases, speeding up the job is a priority for MRO personnel responsible for ensuring a smooth, reliable operation.

Bearing makers heard these concerns and have responded with bearings that are easier to adjust, use fewer tools or require less frequent relubrication. The goal is always the same—saving hours (even days at a time) to avoid costly disruptions throughout a facility.

Among today’s popular bearing designs are some lesser-known configurations that can also relieve the burden felt by busy maintenance staff. If lost productivity is a recurring problem, consider stronger bearing solutions and innovative approaches such as these:

Shaft-Guarding Technology

Conventional housed bearing units (also called mounted bearings) tend to use setscrews or a similar-type locking device that can cause galling or seizing, leading to shaft repair and increased downtime for bearing removal.

Bearings with shaft-guarding technology have two setscrews that do not dig into the shaft in order to maintain grip, thus avoiding life-shortening damage due to gouging and fretting. As the setscrews are tightened, a hardened stainless steel band under the screws is compressed, locking the bearing to the shaft while eliminating any risk of damage from the screws. Other design features tend to include a groove running beneath the setscrews in the bearing inner ring bore that serves to locate the band, while the extended length of the inner ring can also provide extra stability to improve shaft support and reduce bearing misalignment.

Shaft-guarding technology can be a wise investment anywhere shaft replacement is particularly difficult and expensive. Applications tend to include fans and blowers, conveyors, presses and other general industrial equipment.

To understand the impact such bearings can have, consider the example of a typical plant operating 50 pieces of similar equipment, each using two ball bearing housed units per shaft. Based on a 30-year equipment life cycle, a two-year bearing life and six-year shaft life (equaling 14 bearing replacements and four-shaft replacements over the life of a single piece of equipment), savings could amount to over $4,000 annually across the plant—and more than $120,000 over the life of all equipment—due to the reduction in the number of bearing and shaft replacements (based on standard U.S. labor rates, typical unit costs and typical number of hours for repair and replacement of bearings and shafts). Furthermore, the plant could gain up to 525 additional hours of uptime over the life of the equipment due to faster-housed unit replacement on all shafts.

Split-to-Shaft Housed Units

Often, the problems encountered with bearings are not performance-related; more likely they are related to losses in time and expense as a result of the teardown and reassembly operations required to access hard-to-reach bearings. When a housed unit is buried deep inside a machine, it can take days to disassemble the equipment, remove the shaft, service the bearing and reinstall the shaft before resuming operations. Even where housed units are easily accessible, shaft removal or lifting of the shaft and ancillary equipment is often necessary to change bearings.

Split cylindrical roller bearing housed units are the industry’s answer to bearings trapped in high-service-cost locations. These units feature removable housing halves, support caps and bearing components that make it simple to visually inspect or replace bearings in a fraction of the time compared to conventional solid block units.

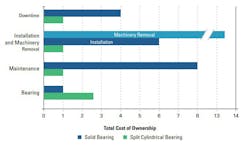

By eliminating the need to remove the shaft to access the bearing, a split-housing design can reduce installation time significantly as opposed to servicing trapped SN/SD/SAF solid housings. In nearly all cases, a split configuration can mean a lower cost of ownership over the life of the bearing as illustrated in Figure 1.

Some split-to-shaft units also employ an angled cast iron support, or pedestal, to allow mounting in locations with low clearance between the base and the center of the shaft. This design feature eliminates the need to raise the shaft to allow clearance for the pedestal yet maintains standard bearing and housing construction requirements.

For those looking for an easier way, a split bearing unit can reduce the total cost of ownership compared to housings with solid, nonsplit bearings. These units are favored for a wide range of applications, including equipment commonly found in cement, chemical, food processing, and pulp and paper plants, as well as for mining, power generation, and oil and gas operations.

Saving Big with Split Bearings

An agricultural products producer in Missouri had an issue with servicing its scrubber fan. Two SAF mounted bearings on the fan lasted only six months at a time, and when workers replaced the bearings, it took up to six hours. Switching to split cylindrical roller bearing housed units resulted in an equivalent savings of $102,000 over one year based on reduced maintenance demands and an increase in production time.

Solid Lube

Providing proper lubrication to bearings is an essential practice in helping to ensure they will reach their targeted service life. The process can be messy and laborious, however, and in many industrial facilities, there is good reason to avoid greases wherever possible, particularly in food and beverage plants where machines operate in close contact with edible goods.

There is growing interest in target industries for Polymer Solid Lube (PSL) bearings that are a grease-free alternative to traditional bearings requiring periodic relubrication. PSL is a microporous polymer structure impregnated with oil that entirely fills the free volume in the bearing between the races, rolling elements, and cage. During bearing rotation, the polymer solid lubricant releases the appropriate amount of oil to lubricate the rolling elements and raceways.

By filling the bearing, PSL also creates an extra line of defense against debris ingress (together, the lube and bearing seals help keep contaminants out). Material and maintenance savings as a result of never having to re-grease critical bearings can be significant, and this is compelling more plant operators to investigate the advantages of PSL bearings that are also finding a place in aerospace, off-highway, and metal processing applications to name a few.

Solid Lube Extends Service Life

A baby food maker experienced excessive downtime due to ball bearings on its aseptic sleeve filling system not being able to survive repeated washdowns. Chemical and water ingress was a big problem, costing the company over $500,000 a year in lost time. Switching to a Polymer Solid Lube increased bearing life to over 12 months, helping improve uptime considerably at the plant.

Engineering Efficiency

Bearings have moved our world for over a century, and while it may seem there is little room left for improvements, the reality is that innovation continues today as bearing makers are not done finding new ways to save their customers time and money. Talk to your trusted adviser about minimizing bearing maintenance with the latest solutions built specifically for industrial needs.

About the Author

The Timken Company

The Timken Company engineers, manufactures, and markets bearings, gear drives, automated lubrication systems, belts, chain, couplings and related products, and offers a spectrum of powertrain rebuild and repair services. The leading authority on tapered roller bearings, Timken today applies its deep knowledge of metallurgy, tribology and power transmission across a variety of bearings and related systems to improve the reliability and efficiency of machinery and equipment all around the world. The company's growing product and services portfolio features many strong industrial brands including Timken, Fafnir, Philadelphia Gear, Groeneveld, Drives, and Lovejoy.