Life is great, everyone is happy, your induction line is running at full production providing hot billets one after the next all, at consistent temperatures. You and your system are doing your part to maximize your company’s profitability. At that moment, something happens at the press and you need to make the right decision about what to do next. Do I keep running and reject billets at full production speed? Do I stop the line and turn it off? Do I reduce the line speed to reduce the number of billets that will be rejected?

The best course of action depends upon several factors:

1. How long it will take to fix the problem?

2. When the system is returned to full production, how long will it take to get back to supplying good forgeable billets?

3. During the holding pattern, how many billets will be rejected?

4. After being placed back into production, how many billets presently in the line will be rejected due to underheated and overheated billets?

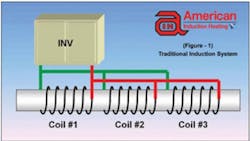

There are a few options for the course of action to take depending upon the answers to the questions listed above, as well as the type of induction-heating system you have. The basic type of induction system is the traditional system as shown in Figure 1. In the traditional linear induction system a single power unit supplies power to multiple coils. Power is controlled by this unit to the entire line of coils. The other type of system is the zone/coil control system as shown in Figure 2 where each zone/coil is powered by a separate inverter. In this type of unit, power to each zone/coil can be independently controlled.

SLOWING DOWN THE SYSTEM

If the problem can be resolved in an estimated minimal amount of time, you can reduce the number of billets that will be rejected by slowing the line down to its inherent “creep” speed. The “creep” speed is the minimum speed at which the system can be continuously run where the thermal profile of the billets along the length of the line can be maintained within an acceptable range. This is desirable so that when the system is returned to full production it can immediately begin to put out forgeable billets while only rejecting the billets that have exited during the reduced output speed “creep” period. At the same time none of the other billets within the line will need to be rejected. Figure 3 shows a Finite Element Analysis of the typical thermal profile of the billets in an induction-heating system during moving steadystate production. Every induction-heating system has some minimum speed at which it can maintain the thermal profile of the billets in the unit before you lose the thermal profile beyond an acceptable range.

Most traditional linear units with a single power supply powering multiple coils can be reduced to 30-50% of the full production speed without sacrificing the average acceptable thermal profile of the billets in the coil line. Minimum creep speed can be further reduced to 5-20% of full speed, realizing that all of the billets in the last coil(s) may be rejected due to being under temperature while all of the rest of the billets in the first coil(s) will be forgeable once placed back into production. The minimum creep speed depends upon the size of the billets, the number of coils used in the system, and how those coils are connected to the power supply. Figure 4 shows how the average temperature of each billet affects holding patterns at different creep speeds. Therefore, when placed back into full production, as the billet exits the coil line, the average temperature of that billet may deviate from the target temperature by the temperature values illustrated.

In zone controlled systems, where each zone/coil in the line has individual power control, the minimum creep speed may be in the range of 5-10% of the full rated production speed without rejecting any billets within the coils once the system is returned to full production. The more independently controlled zones incorporated, the slower the creep speed capability will be.

It must be stated that there is a maximum recommended time when it is practical to remain at any “creep” speed. This time is a function of how long it takes for a billet moving at “creep” speed to travel all the way through the coil line. If this total time is much greater than the expected down time, the best decision should be to shut down the system. As an example, if a 120-in. long coil line is designed to put out a 3-in.OD X 12-in. long billet every 20 seconds, then there are 10 billets in the coil line at any one time, and it takes 200 seconds for a billet to traverse through the coil line at full rated production speed. If the minimum creep speed is 30%, then every 67 seconds it will put out a billet that will need to be rejected if the press is not ready for it to be forged. In this case it will take 667 seconds (11 minutes) before an entire line length of 10 billets is rejected. If the down time is expected to be much more than 15 minutes it would be better to stop the system and shut it off. If considering the decision to turn the system off, the system cold restart time to get back into production must be figured in to your decision. Typically, a cold restart will take one line length of billets before the system will be able to produce forgeable billets. In the case described above that would be 200 seconds rejecting 10 billets to get into full production.

STOPPING, MAINTAINING TEMPERATURE

On any system with a single power supply powering multiple coils, it cannot be stopped to hold temperature. This is due to the fact that the coils are fixed and the ratio of the power delivered to the billets in each coil is also therefore fixed and the temperatures of the billets in all of the coils will approach a constant temperature along the length of the line at the set power level.

On a multi-zone/coil-controlled system, if placed into a stopped hold, it takes only a few minutes to start to lose the thermal profile of the billets along the length of the coil line. All of the billets any given coil will approach a common temperature based upon the power setting in each of the zones/coils.

Figure 5 shows the results of the thermal profile of a zone/ coil control system modeled in Figure 3 after being stopped and held for 30 minutes with no gaps between the zones. The figure clearly shows that the temperature of the billets in each separately controlled zone flattens out approaching the hold temperature of the zone for the coil length. Modeling with gaps would show a temperature drop off on the billets located in the gaps.

SHUTTING DOWN THE SYSTEM

If it is determined that the down time will be longer than desirable as indicated above, the system should be shut down. When shutting down the coil line, either the billets must be cooled back down to room temperature or the coil line must be emptied before restarting production. There are devices available to quickly empty the coil line of billets to help in the practicality of shutting down a line. Restarting the coil line with billets that have not cooled all the way down to room temperature will result in overheated billets coming out of the coil line with billets welded together, or even partial melting of the billets which could cause system coil damage and even more downtime.

CONCLUSION

Whenever a production delay is experienced, there are several courses of action to consider during the delay. The choices are to keep running at full production speed, slow the production rate down to its inherent designed creep speed, or to shut the system off realizing that it will have to be restarted with billets at room temperature. The wrong decision for any occurrence can result in reduced yield as well as increased

| David A. Lazor is the Technical Director and Donald A. Gibeaut is the Forging Director for American Induction Heating Division of Ajax Tocco, Pillar and Westinghouse Induction Companies. Visit www.americaninductionheating.co |