Wrap It Up: Protect Your Teach Pendants Like You Would Your Phone

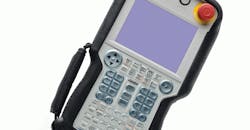

A teach pendant (human machine interface, or HMI) is a critical component for any industrial robot. It allows users to program a robot, make changes to tooling, define weld tracking points, facilitate modifications to production routines, and more.

Like any other operation involving a human worker—handling a robotic teach pendant is subject to our own shortfalls and limitations—we drop stuff! It’s in our nature. For example, look at your own cell phone. You are probably looking at a $600 phone that is protected with a $20 case, or perhaps a $60 bumper… or maybe a cracked screen. Now imagine your phone costs thousands of dollars, and has a large cable attached to it.

Workers inadvertently get tangled in the teach pendant’s cabling and pull the pendant from its cradle or work surface. We place pendants on slippery surfaces and they slide to the floor. Crouched under a welding torch to update seam tracking data, we balance ourselves with one hand on the work piece, and the other tethered to the pendant only by a 1-in. strap of Velcro. Once we lose grasp of the pendant and it hits the floor, it’s likely to suffer damage.

Repairs to broken pendants can cost upwards of $2,500 per occurrence, while replacing a pendant can easily exceed $7500 (depending on the OEM manufacturer). Finding a high-quality bumper capable of mitigating those issues cited above could be viewed as insurance for your production line and automation assets. No one can afford to idle a production line to repair a teach pendant.

As more industrial robots find their way to our manufacturing facilities, it becomes more likely that pendants will suffer damage. Taking a page from your cell phone, pendants need protection. End users and OEMs routinely asked us at Roboworld for solutions to overcome issues with broken teach pendants.

For more on the design features to consider for teach pendant protection, visit the original article on MachineDesign.