Troubleshooting Challenge: 800-Ton Press Suffers from Severe Stuttering

I was called out to troubleshoot an 800-ton press that molded large aerospace seals. The press would close at normal speed for approximately 2 ft., then slow to a creep speed for another 6 to 8 in. to close the two-part mold. Subsequently, pressure built until it reached the required tonnage.

It held the tonnage for about five minutes, allowing the molded piece to cure. Afterward, the press retracted at a super-slow speed so that the piece could separate from the steel die. Then, after retracting 10 to 15 in., a valve shifted it into normal upward speed until fully open.

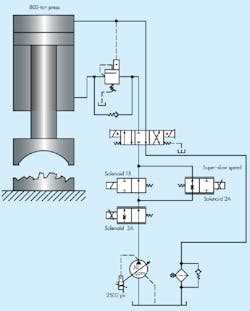

The press started stuttering on the normal downward stroke. It would start and almost stop several times. We determined it must be the main proportional flow control. The super-slow speed, as they called it, worked fine. The diagram shows a simplified version of the hydraulic system mounted on top of the press, which is difficult to access. The super-slow valve is an Eaton ISO-3 mounted in the open, and valve no. 3 is a screw-in cartridge with a slip-on DIN coil mounted behind the pump assembly.

The voltage and current to proportional valve no. 3 were measured at 12 V dc and 4.6 A from the control panel at floor level. Disconnecting the signal to the valve allowed the valve to fully close. The typical command range of proportional valve no. 3 was normally 0 to 8 V dc at about 1.3 A. At 0 V, the valve was able to fully close, and 8 V dc shifted it to fully open.

A PLC program measured the speed of the ram and adjusted the proportional signal to maintain the programmed speed. A brand-new cartridge valve had been installed one week earlier, and a fluid sample indicated an ISO cleanliness code better than recommended.

The press worked fine for a week. So, you would think if it was contamination, it would neither stutter nor fully close when the signal was lost. What do you think caused the severe stuttering?

Find the Solution

Think you know the answer to this month’s problem? Submit your solution by emailing [email protected]. All correct solutions submitted by March 1, 2017, will be entered into a random drawing for a $50 gift card. The winner will be notified, and his or her name will be printed in a future issue. Only one gift card will be awarded to any participant within a calendar year.

This article originally appeared in Hydraulics & Pneumatics.