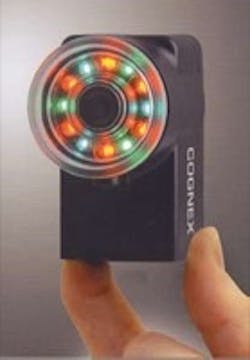

Smaller and lighter than earlier models, the Checker 200 uses red, green, and cyan LEDs to improve contrast.

The developer of high-tech surface-inspection devices, Cognex Corp. recently introduced a new series of inspection sensors, the Checker 200 — initially aimed at assembly and packaging applications. But, the devices' simplicity in use and relatively low cost should attract interest from forgers looking to automate inspection processes.

According to Cognex (www.cognex.com), this new series is as simple to set up as the earlier Checker 101, but with two differences: the new sensors are "much more capable"; and, they are small enough to fit almost anywhere, hence the "next generation" designation.

"Checker 101 set the standard for inspection sensors and eliminated the hassles associated with wiring and precisely mounting multiple photoelectric sensors," Justin Testa, Cognex senior vice president and group business manager, explains. "The Checker 200 series is small, smart, simple, and powerful enough to solve even more challenging sensing applications, and delivers extremely reliable inspection results.

The Checker 200 sensors are one-fourth as big as their predecessors, and noticeably lighter. The Checker 200 series has a different lighting system than the 100 series, which used only red LEDs. The 200 uses red, green, and cyan LEDs, "which combine to give you extremely good contrast," says John Keating, Cognex product marketing manager for sensor products. The design was conceived to be used at varying working distances.

Unlike conventional photoelectric sensors, Checker:

• Detects parts by finding an actual feature;

• Checks features that other sensors cannot;

• Inspects multiple part features simultaneously;

• Overcomes varying part positions on the line, without requiring precise part handling;

• Simplifies set up and operation.

The new inspection sensors offer high-speed inspection capability at rates faster than 6,000 parts per minute. Even on the fastest production lines, Checker is said to be able to inspect multiple part features and deliver reliable, precisely timed, pass/fail results.

The user sets up the sensor by watching a live video of what the Checker sees. Then, the Checker prompts the user to draw a box around a feature that is always present in every single product that goes by, good or bad. Once the user has set the sensor to recognize that feature of the product, the software works to find that feature and check that it meets user-defined requirements..

Checker can inspect multiple part features easily, even when the part position varies. Checker also inspects features that other sensors simply cannot, and delivers precisely timed, pass/ fail results, in rugged, hostile plant environments.

Another important feature is that users can change what the Checker inspects "on the fly."

Each checker system is supplied with PC-based software for setup and operation. The user-interface directs the operator through the setup, and monitoring for results is easy, too. Help screens are incorporated in the user interface to answer frequently asked questions.

All Checker 200 series inspection sensors have a rugged IP67 housing and quick-disconnect cables, as well as encoder-based part tracking, I/O, and high-speed USB connectivity. The Checker 200 series includes the Checker 201, which is best suited for part finding and inspection, and the Checker 202, which includes all the features of the 201 plus ladder logic for custom configurations.

The Checker 200 series varies in price according to model: the Checker 201 is available at $1,495, and the Checker 202, with built-in ladder logic, at $1,695. The 5600 series varies in price depending on the needs of the facility, but starts at $4,995 and tops at $9,495.