Full Automation Sets New Standards in Encapsulation

Regardless of the quantities involved, grouting is a traditional encapsulation process used in the production of electrical and electronic components and assemblies. Circuit boards, transformers, controllers or sensors are coated with a synthetic resin coating or encased in a block of synthetic resin that offers electrothermal insulation and protection against water, dust, and humidity. Two-component systems of polyurethane, epoxy resin or silicone are usually used for this purpose, which have to be processed according to defined parameters.

Dosing and mixing are just as important as the application and pouring of the free-flowing compounds. These requirements are fully covered by the portfolio of Tartler Group, a leading medium-sized plant manufacturer based in Germany. When the group recently received an order from a well-known manufacturer of motor contactors and plug connectors to implement a fully automatic electric encapsulation station, a decisive factor for the award was the finely balanced interaction between the parent company–TARTLER GmbH–and its subsidiaries.

The result was a modern complete solution consisting of a flexibly controllable dosing and mixing system, a robot-assisted application system, and a 2K refill unit that enables continuous encapsulation of already wired assemblies.

Precise Dosing and Mixing

The dosing and mixing epicenter of this encapsulation station is a controlled PU system of the TARTLER NODOPUR series with automated refilling. It has a volumetric flow meter for the A and B components and a Siemens PLC with a color touch screen and allows automatic, variable control of the mixing ratio and output.

The system ensures that the potting compound can be precisely metered and has the desired properties when cured. It masters even the processing of resins in delicate mixing ratios and with high viscosity differences. Its range of functions includes permanent pressure and level monitoring, shot quantity control, recipe management, numerous safety features, and the use of rotating static mixers from Tartler‘s injection molding line.

Accurate Application of Precise Quantities

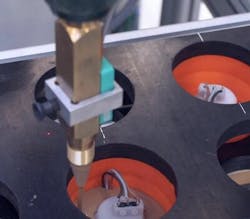

The resin mass produced in the NODOPUR is applied by a 6-axis cobot working in a booth (180 x 170 x 250 cm) with exhaust air extraction. It's connected to the dosing and mixing process by a control unit and guides the mixing head with the outlet nozzle—supported by a camera system—with high precision over a workpiece carrier fed through a pneumatic gate. In doing so, it recognizes which positions are equipped with components standing in mold trays and only allows the defined amount of synthetic resin to flow in there.

As specified by the customer, certain areas of the components are left out of the potting compound. Sensors for sensing distances and positions are located in the robot cell. Multiple windows ensure easy accessibility to all major system areas.

For reasons of work safety, the cell is designed so that the potting process can only start when the booth is completely closed. On its front side, there is space for a roller table for manual potting operations. For this purpose, another mixing head with a tension balancer can be latched into the system. This allows small batches of special parts to be cast manually while the system is automatically processing the standardized series parts.