Enabling Flexible Batch Production With Integrated Machining

WFL Millturn Technologies has always been involved in the field of automation. From articulated robots to gantry loaders, every system combined with a MILLTURN brings a high-tech element and a breath of fresh air into production halls. The acquisition of FRAI Elektromaschinenbau GmbH in 2018 represents another step towards innovation in complete machining, paving the way for a digital future.

Autonomous production methods have long been used by automotive manufacturers, the aerospace industry, and mold construction companies to produce equipment for machine tools. Other sectors with less of a focus on automation are nonetheless showing an increased interest in this area due to the possibility of introducing autonomous night and weekend shifts. WFL Millturn Technologies works with different automation variants such as gantry loaders and articulated robots for automated workpiece loading and unloading, depending on each customer's requirements. Peripheral transport and storage systems for workpieces, tools, and clamping devices can be combined as desired.

This brings some key advantages for the user, such as continuous productivity with minimal operating effort. Automated machines are also ideally suited to repetitive tasks. However, robots are not only used in large-scale series production; there are also many advantages to automation for small batch sizes when used in combination with easy-to-program software.

Customer-specific options, such as unloading samples, inscribing, cleaning, measuring blank parts or even additional processing tasks performed by the robot-like deburring, provide optimal conditions for automation.

Fit for the Future

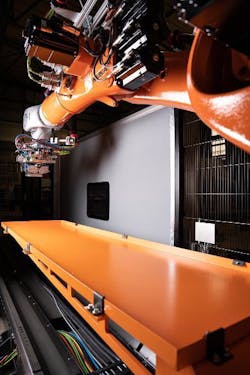

An automation solution recently implemented by WFL has been specially developed for flexible batch production and is designed for the automation of four machine tools for handling different shafts. The 6-axis robot with a 1,102 lb. (500 kg) payload is mounted on a 7th axis. An automatic gripper exchange system has also been attached so that a wide variety of grippers can be connected and disconnected fully automatically as required when the system is operating in automatic mode. An integrated drip tray collects coolant and chips.

Thanks to the fully automatic quick-change gripper system and gripper warehouse, five different grippers are used in specific applications: servo grippers for workpieces and shafts, grippers for prismatic tools (such as long boring bars), grippers for tailstock tips, and grippers for three different inner and outer jaws.

The prismatic tools that are inserted into the machine have a prismatic tool accommodation with a very narrow tolerance range. Before the new tool is inserted into the machine, the robot moves with the exposed guide to a special station in which the guide is blown off to clean it and then coated with oil, creating the optimum conditions for correct installation.

Smart Tool Handling

The jaws can be changed over fully automatically in the automated solution via a special chuck. The tailstock tips can also be changed over automatically using a special gripper. Another special gripper can automatically change the long prismatic tools (boring bars up to 8 ft (2,500 mm) long and 550 lb. (250 kg) in weight).

By using two separate set-up stations for workpieces and tools, tools can be set up and new workpieces can be loaded parallel to machining time and without downtime.

In the warehouse, 20 different sets of jaws, 6 different tailstock tips, 12 individual prismatic tools, and up to 10 workpieces are stored. The gripper station, for the five different grippers, has also been integrated into the warehouse.

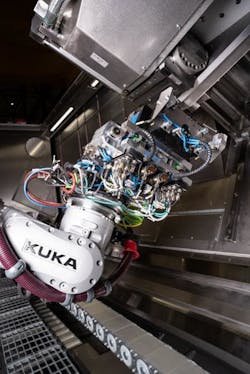

The system has three control levels: the KUKA KRC robot, the Siemens PLC sequence control, and safety technology with the host computer for cell logic and logistics. The host computer—which manages the CNC programs centrally and makes machines available—as well as tool management and material flow planning, optimizes machine use, minimizes downtimes, and enables autonomous or low-personnel manufacturing.

Exclusive Added Value for Customers

Automatic changeover of jaws, tailstock tips, and prismatic tools in conjunction with a servomotor gripper (diameter and length plausibility), which covers an extremely wide product range, allows for set-up-free operation of the machines and automation solution.

The warehouse serves as a "lung" and the host computer as the "brain", meaning that the production plant also manufactures both small series and batch sizes of 1 without restriction. The host computer configures an optimized production program based on the available tools and workpieces so that the system can be operated autonomously overnight or during weekends without manual intervention. The increased degree of utilization not only leads to the production of higher numbers of units but also reduces unit costs due to reduced staff. The high degree of flexibility offered by automation also allows four different shafts to be produced on the four machines at the same time.

The major challenge today in the field of automation is the intelligent combination of a very wide range of technical solutions. You cannot invent or develop everything yourself and this is also not necessary, as there are excellent solutions in a wide range of different areas. Combining these solutions with your own experience and successfully implementing customer projects is a fine art. Although a modular concept has often been spoken of in the past, I use the term "expert modular system", which FRAI is improving daily together with WFL and expanding with every exciting project.

About the Author