QUANTOR-FORM LTD. released QForm 3D/2D version 7, the newest version of its of metal forming simulation software. The developer reported QForm7 uses an entirely new interface, data structure and algorithms written with the most modern programming techniques that allow for more power and flexibility than the previous versions of the program.

The new program runs significantly faster, according to Quantor-Form, thanks to advanced algorithms and full parallelization of the computations. It offers a well-balanced combination of high performance, flexibility, speed, and accuracy with a quick learning curve for new, inexperienced users.

At the same time, the new release is capable of deep analysis for the most advanced users and researchers. It retains the ease of use and familiar features of the previous version of QForm including simulation of both 2D and 3D problems, detection of laps, flow-through and non-fill defects, as well as full tool simulation capabilities, including die stress and die wear.

QForm7 also includes many new features and improved functionality. It has new algorithms for solving coupled mechanical and thermal problems where the temperature and deformation of the dies are calculated concurrently with the simulation. It has both explicit and implicit solvers, as well as elastic-visco-plastic formulation that allow for simulation of residual stresses and distortion. These methods are so effective that the entire press structure can be included in a simulation coupled both thermally and mechanically with the deformation of the billet and the dies.

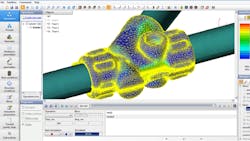

The software’s new architecture allows the simulation core to run independently from the interface, making the graphical interface powerful and flexible. Even while the simulation is still running the user can play the results forward and backward, make crosscuts, measurements, and any other kind of analysis.

New Data Structure

The new data structure efficiently writes and retrieves huge amounts of data, which permits storage of every step of the simulation results. This means that the playback is smooth at 25 frames/second and the results are extremely accurate and nearly indistinguishable from the actual forging.

It also means that a lot of analysis can be done in the post-processor, so the user can test different scenarios without having to re-run the simulation. Even for forgings when the surface collapses creating severe laps, the simulation runs to completion and the results are very accurate.

With QForm7 users can accurately trace tracked points and flow lines forward and backward, produce graphs and numerical data from tracked points, modify the fit of inserts or shrink rings in tool simulations, and calculate user defined functions all in just in few seconds from the post processor. The sophisticated mesh generation algorithms can easily handle formation of laps and folds, intensive shearing deformation, multiple bodies like bimetallic billets or composites as well as pre-stressed die assemblies.

For advanced users, QForm7 allows easy programming and seamless display of User Defined Variables and Functions. Any kind of model like flow stress data, ductile fracture, or microstructure evolution can be added to the program easily with user- defined functions and anyone who has ever tried to do this on other software platforms will appreciate that no compiler is required and these functions are performed at the same speed as the main code.

QForm is well suited for forge shops, cold formers, fastener manufacturers, and extrusion plants that are looking to improve quality while reducing scrap and the costs of tooling. It also works as a tool for education and research due to its flexibility and user-friendliness.

Visit www.QForm3D.com or www.ForgeTechnology.com