Take Control of Fastening and Worker Safety Without Compromise

Day in and day out, industry-wide, manufacturers lose time to workplace injuries and send workers home to their families, impaired and disabled, for days, weeks or perhaps the rest of their lives.

Manufacturers have a responsibility to strive with urgency and persistence toward zero injuries every day. At the same time, the pace of work and the power of tools are ever-increasing to meet the constant demand for productivity. Innovation is the only sustainable solution to increase both safety and productivity in harmony.

Not all tasks on a manufacturing line seem strenuous at first glance, but even seemingly light repetitive work wears on the human body over time.

One of the top workplace health-related issues is repetitive strain injuries (RSI). Stance, reach, repetitive motion, vibration, and torque reaction may all be contributors. As the power of cordless tools increases, the risk factors for RSI also increase.

Thankfully, there are ways manufacturers can limit RSI among their employees. Recent developments in tool control help to minimize exposure to RSI risk factors. Reduced reaction technology offers the best of both worlds; it helps operations maintain productivity and increases worker safety.

Increased Focus on Tool Ergonomics

OSHA reports that U.S. employers pay almost $1 billion per week in direct costs related to injuries. Costs include compensation payments, medical expenses, legal services, and lost revenue from reduced productivity. Though, the price of poor ergonomics is more significant than just compensation expenses—it also impacts quality, uptime, and output.

The impact of RSI builds over time. As a worker begins to experience pain and constrained movement, quality, productivity, and satisfaction are progressively reduced. Well before an injury reaches chronic medical intervention, quality of life can be impacted; exhaustion and crankiness can lead to poor decisions and critical mistakes.

Given the high stakes and human costs, manufacturers should always be looking for new ways to protect operators, prevent injuries and maintain quality.

Assembly tools are used continuously throughout the day, all day every day. Without proper attention to ergonomics, the repetitive motion from using assembly tools can lead to fatigue, hand and arm stress, and even injury. Historically, low reaction tools had very poor control. Manufacturers had to choose between low reaction and high control.

Manufacturers still assume a tool with less reaction does not deliver the necessary control required for proper fastening. Until recently, it’s generally been an “either-or” scenario for manufacturers.

Reducing reaction and maintaining control of your fastening process doesn’t have to be complicated. Employing recent innovations, new assembly tools feature reduced reaction technology that is highly accurate, easy to implement, and more ergonomic than ever before.

Using the Ingersoll Rand QX Series Ergonomic Tightening Systems (ETS), manufacturers have peace of mind that they are providing a safer working environment for their employees while meeting their fastening goals.

Reduce Reaction and Take Control of Your Fastening Process

Depending on the application, manufacturers no longer need to add torque tubes, torque arms or other awkward reaction devices that absorb the torque reaction on behalf of the operator.

Instead of trying to determine how to absorb the torque reaction from a highly-controlled tool, manufacturers can reduce the torque reaction to a safe level for the operator with reduced-reaction tools.

Tools with ETS technology produce short torque impulses using sophisticated control of the tool’s motor instead of delivering a continuous force for the duration of the tightening.

These pulses reduce the average amount of force transferred to the operator and minimize the effect of the reaction. It significantly reduces the reaction that the operator experiences from the tool while delivering the control required for a wide variety of fastening applications.

With an array of reduced-reaction technologies available, manufacturers should consider the process for implementing the new tools in their own operations. For example, does integrating the tool require an extensive motor control setup involving algorithms and bringing in or training experts? Or, can users program the tools themselves without additional hardware or expensive software?

Many tools come ready to deploy with single parameter settings pre-built for the most common application needs. Based on the priorities of the applications, manufacturers have the ability to easily make adjustments to suit their needs.

ETS Offers Operators a Flexible, Safe Fastening Solution

It’s important to find a solution that meets complex fastening needs and is comfortable for workers in today’s manufacturing environment. Until now, manufacturers have been forced to invest in costly, inflexible “monument” solutions to meet these requirements.

Cordless reduced-reaction technology presents a new wave of capabilities that diminish costs for manufacturers with low impact to the operator while maintaining high levels of control.

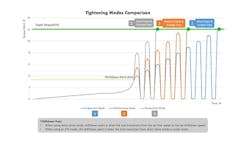

For example, in addition to the standard direct-drive mode, the Ingersoll Rand ETS fastening tools can operate in one of three pre-configured ETS modes: ergonomic, productivity, and performance. These modes make the set-up of assembly operations simple and also give users the flexibility to shift fastening performance based on their goals.

Tools with ETS help users meet the fastening requirements of many applications, safely.

Manufacturing engineers assign any of the three independent ETS modes for each tool configuration according to the needs of each application.

For example, the “ergonomic” mode is ideal for hard joints with steel fasteners. In this mode, the pulses from the tool are softer and deliver less torque reaction to the operator. “Productivity” mode is best for fastening soft joints like rubber gaskets. The rubber joint absorbs the fastening reaction, so the pulses from the tool can be stronger and quicker without injuring the operator.

When ETS mode is active, the operator’s arm movement is limited to a series of smaller movements instead of one large movement. This reduces the chance of injury caused by quick, excessive movements since the operator remains in control of the tool and safely in the ergonomic power zone to prevent injury.

Manufacturing engineers program the tool, and the tool automatically shifts from direct drive mode to the ETS mode during tightening.

The three ETS modes include:

- Ergonomic: Delivers the least amount of energy per pulse. This mode is ideal for applications on hard joints or ones that require difficult arm, wrist or tool angles.

- Performance: Distributes moderate energy per pulse. This mode is best for numerous all-purpose fastening applications.

- Productivity: Delivers the most amount of energy per pulse. This mode is ideal for applications on soft joints or those that require high production rates.

As tool technology improves, tools are more powerful, allowing fastening torque reactions to increase.

Some assembly operators tighten thousands of fasteners in a single workday, and operators who use tools with reduced reaction technology work faster, they're more comfortable, and they have a reduced risk of fatigue or injury. This prevents long-term repetitive motion injury from aggressive impact and from instantaneous pull injuries from the torque reaction.

Internal lab tests at Ingersoll Rand compare similar model QX Series tools with ETS tools. Results demonstrate that the ETS reduces the average reaction force an operator experiences by up to 63%. Across all models, the torque reduction ranges from 41 to 63% and averages 52%.

A workplace injury doesn’t have to be catastrophic to have a detrimental impact on an organization’s bottom line. Low-force injuries have the same ability to take someone off the job as a fall. Reduced reaction tools provide assembly users with a simple solution that gives them control of their fastening process so they can achieve the results they need most.