Digital Search Tool for Steel Grades, Products

OVAKO announced a series of updates to its online Steel Navigator, a digital tool that buyers may use to search for specific steel grades, by group, quality, type of process, product and chemical composition. New features include the new Piston Rod Selector (PRS) module and integration with additional knowledge tool resources, including Material Data Sheets, the M-Steel Calculator and the Heat Treatment Guide.

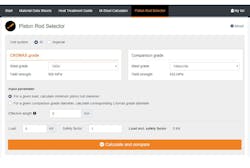

The new Piston Rod Selector module is designed to help users compare how different steel grades used in piston applications will resist buckling. This is important because hydraulic cylinders are usually subjected to compressive axial loads that cause them to fail by buckling. Selecting a higher strength of steel bar (or tube) will give better resistance to buckling and present new possibilities to downsizing piston rods to help reduce both weight and cost.

Users can input the diameter of an existing rod to calculate what diameter would be required with an alternative steel grade to achieve the same safety factor. Alternatively, the maximum load and desired safety factor can be input to calculate the minimum rod diameter for different steel grades.

Another enhancement to the Steel Navigator is access to other Ovako knowledge tools, created to give users in-depth technical information about steel through Ovako’s Welding Guide, published technical reports, white papers, and glossary of steel terminology.

Access to Ovako’s Material Data Sheets (MDS) help users search several hundred of Ovako steel grades using a filtering system based on the parameters that are most relevant to their application. The result is a list of steels that provide the closest match. MDS also offer extensive information about each steel grade, including its chemistry and mechanical properties, as well as production factors like weldability and machinability.

Another feature, the M-Steel Calculator, guides customers to identify the right machine settings based on the steel properties they wish to achieve and the cutting tools they plan to use. Outputs from the calculator include specific information on machine power, chip stream and the expected surface quality for the material.

The Ovako Heat Treatment Guide (HTG) is a tool developed to increase the understanding of how different alloying elements influence steel hardness after quenching and/or tempering. It calculates: 1) CCT-diagram (hardness as a function of cooling rate); 3) Jominy-curve amd DI-value; 3) Core hardness after quenching of a bar with a user-specified diameter (water, oil and air quenching); and 4) Tempering diagram (hardness and strength as a function of tempering temperature)

This tool is valid for most steel grades (carbon steels, engineering steels, tool steels, maraging steels, PH-steels, stainless steels etc.). The input needed to perform a calculation is the alloy composition. Around 1,000 different steel grades are listed, so all you need to do is select the grade you are interested in and the tool will fill in the alloy composition automatically. Other grade compositions may be manually installed.

Learn more at www.ovako.com