Stopping Disruptions Overhead

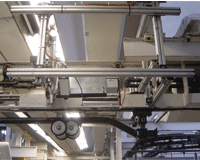

Forging and finishing operations, like many plants that transfer heavy products from one production station to another, are familiar with power-and-free conveyor systems. A power-and-free conveyor is a variation of an overhead chain conveyor; with the latter, the carrier is fixed to and overhead drive chain; but with a power-and-free conveyor the carrier can disengage from the drive chain and "idle" as the chain stays in motion.

Power-and-free systems consist of two tracks: An overhead ("power") track that holds a conveyor or carrier chain and a lower "free" track. The overhead track transports the chain-driven trolleys. It's this type of system that Volkswagen uses in its Golf assembly line in Wolfsburg, Germany. The final assembly work is done while the vehicle bodies are hanging from the power-and-free conveyor system before the cars proceed to the next production stage. The high-volume throughput has a considerable effect on the assembly line components. When slack in the chain link increases, for example, the trolley bolts can be deformed or break off due to wear and abrasion.

Also, the trolley wheels are subject to extreme stress. Broken wheels and damaged ball bearings lead to production downtime that is expensive as well as disruptive. If material fatigue is not detected in time, the production process can be impaired or interrupted, resulting in unexpected loss of throughput and lost profits. Jammed or unhinged trolleys require tedious repairs. Defective trolley wheels can lead to damage to the materials or parts in production.

Until recently, VW trained workers to inspect the trolley wheels, and inspections had to be performed about 10 feet above ground with the inspector in an uncomfortable position. With a throughput of approximately 2,200 trolleys per day, it was an exhausting task and not all errors were detected.

The Volkswagen plant's managers wanted an automated solution. "A product that was quick to install and would provide a reliable trolley wheel inspection was important to us. We wanted to proactively detect material fatigue to avoid corrective measures," according to Wolfsburg maintenance manager Jürgen Bastek.

A technology developed by PSI Technics (www.psi-technics.com/E) provides the solution. The package involves fully automated industrial image processing using 3D and 2D cameras. 3D cameras monitor the trolley wheels on both sides of the overhead tracks of the power-and-free system that transports the empty trolleys back to the beginning of the assembly line. The images are analyzed directly inside the cameras. If certain trolley wheels exceed the predefined tolerance limits, the corresponding data is saved in a database.

The 2D cameras read trolley ID codes and store them in the database. When tolerance limits are exceeded, a command is transmitted to the PLC and the corresponding trolley is removed from current production for service. Then, the maintenance technicians can perform a detailed inspection or repairs, if necessary.

Volkswagen has been using the PSI Technics Inline Control System successfully since June 2011. It was installed in just a few hours during planned, production-free maintenance periods. All additional tasks, such as system configuration and adjustment, took place during regular production. Once the system had been configured, no additional maintenance was necessary. PSI Technics provided the complete Inline Control System, including all required interfaces and documentation.

Thanks to the Inline Control System, VW's maintenance team can concentrate on strategically important projects, rather than repairing defective trolleys retroactively. "The fully automated inspection of our power-and-free installation guarantees a smooth production process," according to Bastek. "Costly production downtimes are a thing of the past."