Conveyor Dust and Spillage: The Importance of Skirtboard Sealing Systems

A manufacturing leader in belt conveyor accessories, Martin Engineering designs products around safety to promote an efficient and clean working environment, and part of that is manufacturing properly sealed conveyor chutes for bulk handling.

The latest innovations the company has devised are the ApronSeal Double Skirting for extra sealing in high dust environments and a self-adjusting skirting system with limited maintenance.

This article explains some of the issues older designs experience, how a sealed environment improves workplace safety, and how skirting can reduce labor costs for cleanup, in turn, lowering the cost of operation.

When tons of transferred bulk material hits a moving belt, three things happen: fines scatter, cargo shifts as it settles, and dust becomes airborne. The impact can create turbulent air that seeks the easiest escape from any gap it can find, carrying dust and fines with it. These gaps generally appear on the sides of the enclosure between the chute wall and the belt. Skirting systems address the challenge of containing fugitive dust and spillage.

ApronSeal Double Skirting:

- Provides effective sealing on higher speed belt

- Offers dual life, dual sealing system in a one-piece construction

- EPDM 70 durometer rubber composite with low-abrasion index characteristics

- Up to 300 ft (91 m); No splices are required even in long applications

- Applicable on 0, 20, 35, and 45-deg. troughing angles

Self-Adjusting Skirting:

- Provides effective seal on conveyors with as little as 1.25 in. (32 mm) of free area on each side of the belt

- Rubber sealing strip available in continuous lengths up to 300 ft (91 m)

- Sealing strip provides a wear life of 2 in. (51 mm)

- Easy replacement of a worn sealing strip; remove linchpins and replace the pre-punched rubber strip

- Not suitable for reversing belts or belt with roll-back

What Is a Skirtboard Sealing System?

Usually made from natural or SBR rubber (or specialty formulations for specific applications such as underground mining, food, etc.), the skirting extends down the entire length of the transition enclosure and is generally tapered at the bottom to match the trough angle of the belt. It's intended to maintain a seal on the enclosure and help trap any fine particles and dust that are not contained by the wear liners and chute wall.

Skirting Issues

As the skirt edge loses its seal, gaps are created, which allow material to become entrapped in a “pinch point.” This causes abrasion that gouges or chafes the surface of the belt down its entire length.

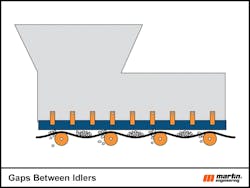

Some of the major issues from entrapment include scalloping, when wedged material causes excessive wear, and grooves when debris collects under the skirt causing friction damage. Regardless of the belt tension, belt sag will create a space for fugitive dust to escape or for material to become entrapped (Figure 1). This is avoided by retrofitting a skirt sealing system with impact cradles or edge support rather than rollers in the loading zone.

Proper Enclosure Configuration

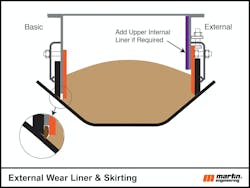

Wear liners are typically welded to the inside of the chute wall with the skirtboard attached on the outside using an adjustable clamp system. However, the internal design (Figure 2) can allow some material buildup in the gap between the wear liner and the skirtboard, depending on the size of the aggregate.

External wear liner and skirting configurations place both pieces of equipment outside the chute wall (Figure 3). Placing the skirt seal and wear liner outside of the chute makes it easier for workers to perform adjustments safely. The result is a better seal on the belt and less material entrapment.

Self-adjusting skirting maintains a seal automatically as the belt path fluctuates due to its design, without the need for adjustment and only periodic inspection. A low-profile skirting assembly should need only 6 in. (152 mm) of clearance for installation and maintenance in small spaces.

Skirting Best Practices

Since skirts are wear parts, it's important that they are easily installed, adjusted, maintained, and replaced to avoid dust and spillage, mitigate downtime, improve workplace safety, and reduce the cost of operation. Managers contemplating a capital investment in a skirting and wear liner system should consider:

- Hiring an outside engineer to design the best system for the application.

- Installing equipment that features external maintenance.

- Using a skirting strip that extends the entire length of the chute to avoid seams.

- Choosing skirting material that is free of fabrics, with a lower abrasion resistance than the belt.

- Installing a self-adjusting system.

- Choosing the option with the least worker exposure to equipment hazards.

Case Study – Grain Terminal in Brazil Reduces Dust

The Port of Santos in São Paulo is the busiest in Latin America. Operating at Terminal 26, T-Grão manages the import and export of over 4 million st/y (3.6 million mt/y) of malt, wheat, soy, and maize. Transfer points at T-Grão range between 32 to 50 ft (10 to 15 m) in height.

The fugitive emissions affected air quality and visibility in the immediate work areas, forcing personnel to wear protective masks when working around any part of the conveyor system. The dust often traveled beyond the site line, sparking complaints. Before the chute upgrade, a cleaning crew of 45 workers spent ~24 hours per month on dust and spillage cleanup.

Martin Engineering technicians constructed a longer sealed enclosure with the ability to control airflow and give dust extra space to settle. They added several other critical components including external dual seal skirtboard and wear liner system. Impact cradles and slider cradles replaced the idlers to seal gaps in the chute.

Operators immediately observed significant results. As material moved through the system, particulates remained within the enclosure and either collected in the dust bags or settled back into the cargo flow. After a lengthy observation period, operators report that there has been less downtime for cleanup and maintenance, as well as improved workplace safety.

Conclusion

By installing modern skirtboards that prevent fugitive material from leaving the loading chute, operators can reduce worker exposure to hazards, minimize labor for maintenance and cleanup, improve equipment and belt life, and achieve better compliance. The savings on labor and operating costs alone provide a sound return on investment, but the improvement to workplace safety should be the only motivation needed.

Dave Mueller is a long-time employee of Martin Engineering, having started his career with the company in 1986. He has since established himself as an expert in conveyor accessories. A graduate of Penn Foster College with a B.A. in Business Management, Dave has 10 years in Research & Development on conveyor products, 26 years as a Conveyor Product Manager, is a prolific contributor of articles, and has several patents.

About the Author

Dave Mueller

Product Manager, Martin Engineering

Dave Mueller is a long-time employee of Martin Engineering, having started his career with the company in 1986. He has since established himself as an expert in conveyor accessories.

A graduate of Penn Foster College with a B.A. in Business Management, Dave has 10 years in Research & Development on conveyor products, 26 years as a Conveyor Product Manager, is a prolific contributor of articles, and has several patents.