Different Types of Cutting Tools for Deep Hole Drilling

The global drilling tools market was valued at USD 5.79 Billion in 2016 and is expected to grow at a CAGR of 4.75%, during the forecast period, to reach USD 8.61 Billion by 2022.* Producing deep holes in an effective and efficient way is considered a challenging application. Cutting tool manufactures need to provide their customers with a product that has predictable tool life, accurate surface finish, and repeatability at a good price to be competitive in the market. Thomson Mathew, ANCA Product Manager explains the different types of cutting tools for this application and how to overcome some common challenges in deep hole drilling.

Thomson Mathew starts: Deep hole drilling is a process to produce holes in metal at high depth-to diameter ratios on CNC Machines. For normal drilling processes, the length to diameter ratio will be less than five times the diameter and if the length to diameter ratio goes beyond five, the process is called deep hole drilling. This can be effective in diameters ranging from 1 to 200 mm (0.04 to 8.00 in) and will require special drills with through coolant holes to deliver high-pressure coolant to evacuate chips cleanly and achieve hole tolerances and surface finish. Some common deep hole drilling processes include gun drilling, BTA drilling (Boring and Trepanning Association), and conventional carbide twist drills. All these processes have their own merits in deep hole drilling based on hole diameter and tolerances.

BTA drilling is an effective method of drilling deep holes, as it is cleaner, reliable, and capable of achieving larger diameters at higher feed rates. BTA drilling is effective in holes from 20 to 200 mm [0.80 to 8.00 in], a larger size range than gun drilling and carbide twist drills.

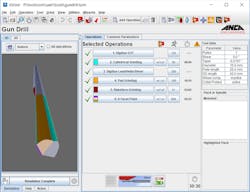

Gun drilling was originally developed to drill out gun barrels and is used commonly for drilling smaller diameter deep holes. The depth-to-diameter ratio can be even greater than 300:1. The key feature of gun drilling is that the bits are self-centering; this is what allows for such deep accurate holes.

Carbide twist drills with through coolant holes are also commonly used in several deep hole drilling applications. The challenge is to manufacture and re-grind these drills with minimal runout and requires an additional axis on machines to support the flute grinding process. ANCA CNC Machines have this ability to support and manufacture the full range of long series drills with minimum runout with the P-axis Arobotech system. The system also caters for the back taper on long series drills by allowing the support pads to adjust automatically to the taper.

Common challenges in deep hole drilling

Through coolant or internal coolant - This improves chip evacuation while cooling the cutting edge. Coolant is flushed down to the bottom of the hole, which, in turn, is pushing the chips back up toward the top. ANCA software has the ability to design and verify the coolant holes right at the design stage to avoid coolant hole breakage into flutes and eliminating scrap.

Hole Straightness - The “margin or radial land” is the portion of the drill that is actually contacting the hole. A single-margin drill (one margin per flute) is preferred in long chipping materials. Single margin drills provide additional clearance in the longer chipping materials whereas a double-margin drill (two margins per flute) provides excellent hole straightness compared with a single margin drill. Although not as common, double margin drills with a floating second margin are also available where a compromise can be made on hole straightness and chip evacuation. So, more margins add accuracy while maintaining a higher surface finish but restrict the amount of clearance for chip evacuation.

Tool runout control - One of the most significant challenges of deep hole drilling is maintaining control of runout, which increases with cutting tool length. A more accurate method of tool holding like the premier plus, combined with the P-axis Arobotech support can deliver the tools with minimal runout and deliver longer tool life.