Universal Robots has 60+ UR cobots in more than 30 booths at the show. Below are the new UR robot/cobot solutions making their debut.

Pro Spot International

The world's first cobot spot welder—Pro Spot Automation—uses a UR arm on its smart i5 auto welder. With the i5s resistance spot welder, Pro Spot has developed a lightweight solution, delivering 2 to 3x more manufacturing capacity than manual spot welding.

“We married our most sophisticated spot welder with Universal Robots’ safe, unrivaled technology. The combined platform is a powerhouse of productivity and throughput greatly benefiting any manufacturer who joins sheet metal through spot welding," says Ron Olsson, president and founder of Pro Spot.

The handheld Spot Welder has been integrated into a safe, easy-to-use cobot automated welding workcell. With advanced welding technology, the robotic welder includes features such as auto weld, a built-in library for different materials, a touch screen interface, complete data capture, Wi-Fi, a synchronized log of welding position with weld schedule and datalog, and much more.

THG Automation

Another manual welding tool now incorporated in a cobot application is the rotational positioner from THG Automation, addressing any welder who ever struggled to weld circular or odd-shaped parts. The servo-controlled positioners integrate with new or existing THG Automation welding systems. These can be purchased with a system or added to existing UR E-Series collaborative robots.

Each positioner comes with URCap software, robot controller connections, positioner cabinet, a safety connection for laser scanners and light curtains, a servo amplifier, and a connection cable.

UR's UR20 Cobot

The UR20 cobot with a 44 lb. (20 kg) payload and 6-ft (1,750 mm) reach starts shipping later this summer and is on display at the UR booth in a machine tending application, loading and unloading heavy workpieces into a machine fixture.

Rocketfarm

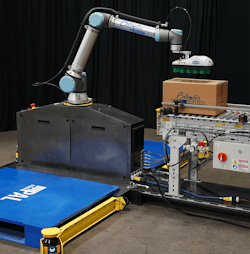

With MyRobot.cloud, Rocketfarm is launching the first digital twin solution developed for palletizing with UR cobots. The solution is sought after by integrators who can now quickly verify customer projects on-site and is showcased with partner Columbia/Okura’s miniPAL, a mobile palletizing solution powered by the UR10e cobot arm.

The miniPAL can palletize at two pallet locations for optimized productivity. The latest design includes three area safety scanners that detect human presence in the palletizing work envelope. This ensures safe (collaborative mode) operation in the presence of workers, while allowing the miniPAL to operate at maximum rates while individuals are not within the palletizing work zone. A ‘big brother,’ the miniPAL+ featuring the UR20 cobot, will be available for preorders in the booth.

Rapid Robotics

Its partnership with UR, RapidRobtics has supported its expanded offerings to include end-of-line applications such as box-building, packing, and palletizing. At the UR booth, Rapid is displaying a case-packing operation using a UR5e that is integrated with Rapid’s Robotics, software stack. Attendees can see the pre-trained cobot pick up multiple bottles at once and then pack them neatly into a case.

INPRO Technologies

INPRO is demonstrating an entire process cycle with UR cobots through a fully integrated gasketing station for instantaneous curing with plasma treating, liquid gasket dispensing, and UV light. The station features a UR cobot arm performing both assembly/disassembly, material handling, and process control tasks, all while serving as the main coordinating ‘PLC.’

Reliabotics

RoboRoom is a UR-based modular turnkey automation work cell, designed for a variety of automation applications. RoboRoom will be showcased with an inverted UR5e robot performing metal parts deburring using ATI tools and its own proprietary, recycled CO2 surface-cleaning technology.

Robot27

Operator Interface allows operators to easily access and run pre-programmed robot programs and functions without touching the UR teach pendant. Machine operators can execute these tasks with just a few clicks and with no possibility of altering any programming.

Automate is the leading automation showcase in North America, offering hands-on, front-row experiences to current automation trends in the industry. Automate 2023 is running May 22-25 in Detroit, Michigan.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.