Octopus Robot Creates Smarter, More Energy-Efficient Automation

Key Highlights

- Octopus-inspired robots offer energy-efficient alternatives to factory automation.

- Suction intelligence enables safer handling of delicate or irregular parts.

- Soft robotics reduces reliance on motors and chips, cutting costs and energy use.

- Potential applications include manufacturing, agriculture, and medical devices.

Octopuses…octopi? Either way, these brilliant aquatic escape artists have always fascinated me. From pranking zookeepers to solving puzzles in the wild, they constantly remind us that they're more than just eight arms with suckers. Honestly, sometimes I wonder if suckers on my arms (or a tail, or wings…) wouldn't be more useful than opposable thumbs.

That's exactly why engineers lean on biomimicry, copying clever designs from nature when the human body isn't always the best model for the job. Case in point: a team from the University of Bristol's Faculty of Science and Engineering just published a study in Science Robotics on a new octopus-inspired robot.

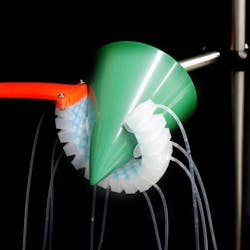

Instead of rigid joints, motors, and processors, this robot uses fluid flows of air or water to move and suction like an octopus arm. While it can stick or suction to things, the real innovation is that it can also sense its environment, adapting to what it's suctioning to—without a central computer.

If a suction unit touches, say, an egg, it "knows" how firmly to grip without breaking it, adjusting automatically as it goes. The team refers to this ability as "embodied suction intelligence", since the robot's structure and physics handle the decision-making, mimicking how an octopus's nervous system is spread through its arms.

This suction intelligence works by coupling suction flow with fluid circuitry, allowing the robot to gently grasp delicate objects and even use adaptive curling to encapsulate items with irregular or unknown geometries. By analyzing pressure responses within the suction cups, it can achieve high-level perception—detecting contact, classifying its environment and surface roughness, and even predicting how much force an object is applying back.

The team wrote in their paper that, "Octopuses exploit an efficient neuromuscular hierarchy to achieve complex dexterous body manipulation, integrating sensor-rich suckers, in-arm embodied computation, and centralized higher-level reasoning. As in octopuses, suction intelligence executes most of its computation within lower-level local fluidic circuitries, and minimum information is transmitted to the high-level decision-making of the 'brain.'"

This invention falls under the field of soft robotics, which uses flexible materials like silicone or gels instead of rigid metal frames. Soft robots bend, stretch, and deform safely, making them ideal for handling delicate objects or interacting with people.

Unlike traditional robots, which burn energy running constant feedback loops (sensors> processors>motors, ad infinitum), this design outsources the thinking to the suction itself. The flow of air or water both sticks and senses: surface type, texture, pressure, and even whether it’s touching air or liquid. Each suction cup acts semi-independently, reducing the need for power-hungry chips and motors. This creates less energy, fewer moving parts, and a safer design overall.

While this robot doesn't look like much, its future applications are readily apparent. With a simple and low-cost design, it could pave the way for a new generation of soft robots that are safer, smarter, and more energy-efficient.

Potential use cases include picking delicate fruit and vegetables in agriculture, handling fragile items in factories, anchoring medical tools inside the human body, or creating soft toys that are safe for kids since there wouldn't be rigid seams for fingers to get caught in. It could also be used with wearable devices, such as smartwatches or assistive devices that suction comfortably to skin, adapting to hair, sweat, or shifting textures while staying in place.

I particularly think the medical angle is the most interesting. Inserting cameras, scopes, or surgical instruments into the human body is a tricky challenge. Tools need to remain steady inside a slippery, moving environment, and current anchoring methods are often rigid—sometimes damaging tissue or organs, and often relying on a human hand to hold them steady. A robot built on this design could suction gently to tissue without puncturing or clamping, adapting to uneven or wet surfaces. And since it doesn’t require heavy electronics, it could be made small and biocompatible for minimally invasive surgeries.

Lead author Tianqi Yue explained that this new octopus-like robot builds on the team’s earlier work, creating an artificial suction cup that mimics how octopuses stick to rocks using soft materials and water sealing:

"This research brings that work on, from using a suction cup like an octopus sucker to connect to objects to using 'embodied suction intelligence'—mimicking key aspects of the neuromuscular structure of the octopus in soft robotic systems."

The team is currently working on making the system smaller and more reliable for real-world use. They also aim to combine it with smart materials and AI to improve its adaptability and decision-making in complex environments.

"It's fascinating how a simple suction cup, with no electronics inside, can feel, think, and act—just like an octopus arm," concluded Tianqi. "This could help robots become more natural, soft, and intuitive to use."

Fun Innovations Friday

Created by the editors of New Equipment Digest, Fun Innovations Friday is a feel-good blog that showcases how advances in science, math, engineering, and technology are making our world more whimsical. Here's another post that is guaranteed to brighten your day.

The Quirky Side of Robotics: Exploring ADAM, MarsWalker, and MarsCat

From a drink-pouring humanoid to a stair-climbing vacuum lift to a robotic cat, these robots show how odd—and fascinating—automation can get.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.