Automation continues to make inroads in every industry in the United States. Retailers are among the latest industries to fully embrace robots, with more than 60% reporting difficulty in finding qualified candidates to staff their stores, according to Verint.

“Leveraging automation is absolutely critical to fill workforce gaps and create a connected customer engagement strategy of humans and bots,’’ said Jenni Palocsik, Vice President of marketing insights, experience, and enablement for Verint as the holiday shopping season ramped up in November.

Robots are gaining traction in the food industry as well. In the wake of the coronavirus pandemic, Dexai Robotics developed solutions that reduced human contact with food that helps reduce the spread of pathogens and viruses, and keeps food fresh for a longer period of time.

“The global pandemic has altered the way that we eat,’’ said Justin Rooney of Dexai Robotics.

Most autonomous solutions, however, have stayed out of the kitchen. There have been a few forays—companies have made devices to mix drinks and serve coffee—but the delicate art of food preparation, including everything from temperature control to the right mix of seasonings, has remained in the hands of human professionals.

Now, that too is changing.

RoboEatz, a Canadian startup, has developed an Autonomous Robotic Kitchen (ARK), in which robots can prepare multiple hot and cold meals without sacrificing quality. Founders Konstantins Korchomkins and Janis Poruks have designed a solution in which a robot sorts solid and liquid ingredients and then cooks the food.

Like many other food service providers, Poruks faced labor shortages in a decade-long run as manager of a restaurant chain in Latvia. “It is difficult to find personnel who want to work in catering,’’ Poruks said. “And the quality of the food prepared is often inconsistent. This is not acceptable in the catering industry. We also wanted to make sure that fresh produce was used as a matter of principle.”

Cell Service

The heart of the ARK is a “kitchen cell” which features an industrial robot in the middle. Mounted on two of the inner walls are 50 containers for solid ingredients and 30 for liquid ingredients. A third wall includes utensils, cooking pots, and mixers.

When the robot cooks, it grips one of the containers and tips the right amount of ingredients by weight into the working device. The unit repeats the step as often as needed, adding each ingredient without physically touching any of them. The gripper handles only the containers. The prepared ingredients are combined, cooked, and garnished as necessary.

The cell can prepare up to 70 meals while automatically cleaning itself and refilling the contents of ingredient containers. While the system is automated, Korchomkins said that human recipe designers have full control of the prepared dish. Salads, soups, pasta, vegetarian, and meat dishes can all be prepared in the ARK.

Mixing Bowl

Like chefs selecting ingredients for a freshly prepared salad, Poruks and Korchomkins used a variety of products and technology to create the robotic kitchen.

Poruks produced individual parts for the first prototype with 3D printing materials. When the time came to scale up, Porukus and Korchomkins turned to the Low-Cost Automation department at igus, the Germany-based manufacturer of motion plastics.

The robot cell experiences frequent movement and requires significant bearing support. “We are taking advantage of numerous igus product areas,’’ Korchomkins said. “Plain bearings, linear technology, swivel joints, and energy chains are all incorporated into the application.”

An RBR energy supply system with a rotation angle of 360 degrees in the robot’s first axis delivers energy and signals to the robot. igubal fixed flange bearings and rod ends, which require no lubrication or maintenance, allow for the pivoting movements of both the wok and the ingredient boxes, making them self-aligning.

Automation: Facts & Figures

Growing Sales: Robot sales reached $646 million in the first quarter of 2022, a 25% increase over the previous best quarter.

Source: Association for Advancing Automation

Jobs: By 2030, 20 million (8.5%) of the global manufacturing workforce will face job losses due to automation.

Source: Oxford Economics

Where: The most vulnerable jobs are in office administration, production, transportation, and food preparation. The jobs are deemed “high risk” with over 70% of their tasks potentially automatable.

Source: Brookings Institution

Costs: While some automated solutions can reach $150,000, more low-cost solutions are now available. igus, a Germany-based manufacturer, offers an automated solution for slightly more than $5,000.

Did you know?

The automotive sector is perhaps the largest user of automated solutions. Manufacturing, welding, assembly, and material handling are all tasks that can be performed by robots.

For bearings, iglide MCM clip bearings serve as shaft guides in metal sheet connections. Linear movements of the individual axes on the containers are implemented with drylin linear technology. The company’s drylin SLW linear modules ensure that the gripper functions safely. A reverse lead screw opens and closes the gripper arm.

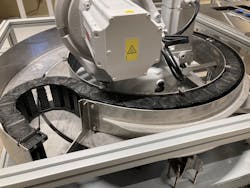

The final piece to the food-production puzzle is a triflex multi-axis cable carrier that can move in three dimensions and has a retraction system mounted in the robot arm. The triflex cable carrier is a frequent component of automated solutions, as it offers superior service life, reliability, and easy assembly.

One of the challenges in preparing automated solutions for food service is finding food-compatible components. igus manufactures FDA-compliant products that are cost-effective, simple to implement, and provide a swift return on investment, especially for small businesses.

Personal Touch

While the ARK robots prepare and cook the meal, the developers still left room for human creativity to dictate the dish that is delivered to the table.

“When it comes to recipes, the restauranteur has free rein,’’ Korchomkins said. “We provide the user interface where he drags and drops recipe elements and preparation data such as cooking time and temperature.”

Based in Toronto, the partners started developing their ARK in 2019. Poruks had nearly a decade of technical expertise in running Woki Toki, a fast-food chain in Latvia. Korchomkins ran a company providing engineering services to the aerospace industry. Their team includes mechanical and automation engineers, CAD specialists, chefs, food technologists, and entrepreneurs with operational expertise in scaling multiple businesses globally.

After the construction of several prototypes, two years of testing, and continuous improvement, the first “robot kitchen” has already been put into operation and more are sure to follow. “It’s quite clear that the system must be profitable for the restauranteur,’’ Poruks said. “We expect a payback period of two to three years.”

“Businesses today are under constant pressure to lower costs while improving operational efficiency. Labor shortages, reducing costs, improving workflows, and reducing workplace accidents are [among] the reasons why organizations are seeking automated solutions.”— Alexander Muehlens, Head of low-cost automation, igus

Breaking Barriers

The barrier to entry for many businesses seeking to enter automation is cost. One of the advantages for RoboEatz was working with the igus Low-Cost Automation department, which concentrates on working with businesses to provide customers with ready-made systems.

Customers have the option of purchasing individual components directly or from a single source. The ability of igus to manufacture products that can be used in the food industry was also critical.

“The bearing and drive components are lubricant-free, which is a key point in food processing,” Poruks said. “They are very durable, and their service life can be calculated online. It is also important for us to be working with a supplier with a global presence. After all, we want our robotic kitchens to be used internationally.”

The applications in which RobEatz could be implemented are varied. Grocery and convenience stores, airport and transportation hubs, business offices, quick and casual restaurants, health care facilities, schools, and senior care centers could use automated solutions to prepare and cook nutritious meals. The only thing missing will be the toque blanche.

While not yet mainstream, automation just might be the salvation for an industry grasping at straws to try and solve its labor issues. Restaurants remain 565,000 jobs (4.6%) below their pre-pandemic staff levels, the largest deficit among all U.S. industries, according to statistics from the National Restaurant Association released in November.

Restaurants are one of many industries reeling from the fallout from the pandemic, and inflation, supply chain issues, and high turnover rates continue to plague many of them. Perhaps, however, automation can help some of them get back on track.

Thomas Renner writes on trade industry topics for publications throughout the United States.

About the Author

Thomas Renner

PR Account Executive - Mercury Marketing Comm.

Thomas Renner writes on manufacturing, engineering, building, construction, and other trade industry topics for publications throughout the United States.