Hiroshima University Researchers Develop Non-Contact Vibration Monitoring for Industrial Robots

Key Highlights

- Hiroshima University researchers developed a non-contact vibration monitoring system for robots using high-speed imaging.

- Using Digital Image Correlation (DIC) and software-defined measurement points, they tracked robot vibrations without physical sensors.

- Testing across multiple robot positions captured high and low-frequency vibrations at the same time.

- High-speed cameras like the Mikrotron EoSens 2.0CXP2 enable full-field vibration mapping.

Industrial robots perform many critical tasks in manufacturing, including welding, assembly, painting, material handling, and inspection. Keeping these robots reliable depends on vibration monitoring, since abnormal vibration patterns often signal mechanical issues such as imbalance, loose components, bearing wear, or structural degradation.

Most vibration monitoring relies on physical sensors, like piezoelectric accelerometers. While accurate, these sensors add cost and weight to robot arms, can interfere with motion, and require cabling that is prone to flexing, wear, or failure over time. These challenges have driven interest in non-contact techniques that can support predictive maintenance without physically altering the robot.

Researchers at Hiroshima University in Japan have developed and tested a non-contact vibration monitoring system that combines Digital Image Correlation (DIC) with high-speed imaging from a Mikrotron camera. DIC is an optical method used to measure full-field surface deformation, displacement, and strain. The system captures vibration behavior across an industrial robot’s structure without the need for physical sensors.

To test the system, the researchers used a six-degree-of-freedom vertical articulated industrial robot. They applied a random speckle pattern to the robot's surface to enable optical tracking and attached a small vibration exciter to create controlled vibration.

Images were captured using a Mikrotron EoSens 2.0CXP2 high-speed camera with a 20 mm lens, mounted 1.2 meters from the robot. The camera's 2-megapixel CMOS global shutter sensor and four-lane CoaXPress 2.0 interface allowed high-resolution capture of 1920x1080 pixel images at 1,000 frames per second, with a spatial resolution of 0.6 mm per pixel.

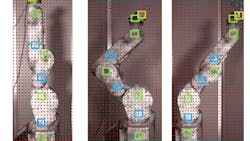

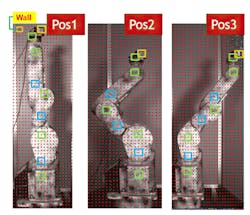

Captured video was divided into individual frames and segmented into hundreds of smaller regions, creating a network of virtual vibration sensors across the robot. Rather than attaching physical sensors, the system tracked vibration at eight key points on the robot, defined in software using DIC. A GPU-accelerated algorithm developed in C++ processed the high-frame-rate image data and tracked changes in the speckle pattern over time to generate two-dimensional vibration maps.

Mikrotron EoSens 2.0CXP2 High-Speed Camera:

- 2 MP CMOS global shutter sensor, capturing up to 2,240 fps internally

- CoaXPress 2.0 interface with up to four lanes for high-speed data transfer

- High sensitivity: 20 V/lux @ 550 nm for detailed imaging in low-light conditions

- FPGA-enabled for real-time image processing and GPU-accelerated analysis

- Supports long cable runs via HD-BNC, reducing installation complexity

- Open platform design allows integration of custom IP for specialized measurement or inspection

Why it matters: The EoSens 2.0CXP2 provides the speed, resolution, and processing power needed for full-field, non-contact vibration analysis of industrial robots.

Learn more: View full product details

Testing covered three representative robot postures from an actual operating cycle: a home position, an intermediate extended position under maximum load, and a return to home. For each posture, the first frame served as a reference, with subsequent frames used to calculate displacement and vibration behavior.

According to the researchers, the system successfully captured both high and low-frequency vibrations simultaneously across the moving robot. This type of full-field, multipoint measurement is difficult to achieve with conventional sensors. By detecting vibration changes early, the approach could help manufacturers move toward predictive maintenance.

Researchers at Hiroshima University have stated that their future work will focus on improving system reliability and extending it to real-time vibration monitoring during active robot motion. The researchers also plan to test additional robot configurations and explore multicamera stereo imaging for three-dimensional vibration analysis.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.