When DAQRI unveiled the Smart Helmet in 2016, it was a glimpse into the future of augmented reality. Step-by-step work instructions, solid to-scale 3D models, even thermal imaging, displayed right onto the face shield. There was always speculation and theorizing about what the worker of the future would look like. Seeing this sleek white helmet with the reflective blue face, and what it could do in an industrial environment, made it clear that future was closer than we thought. The form factor, array of sensors, and powerful 6th Generation Intel Core m7 Processor put it at the head of the wearable class, and is why we awarded it a 2017 Innovation Award. After putting aside how awesome it looked and the potential it projected, users started to realize the 3.3-lb. helmet would weigh even heavier after several hours of use. Also, those sophisticated electronics generated a lot of heat, making the experience even more uncomfortable over an extended period. And considering the price tag of $15,000, the Smart Helmet didn't seem like a wise investment for most companies.

The wonderful thing about innovation is that it never has to stop. DAQRI took its initial industrial users' feedback and polished this developmental platform into the DAQRI Smart Glasses, available now for $4,995. They may not look to be ripped right out a futuristic sci-fi movie or video game, but they are a heck of a lot more likely to be adopted by industry this year. We recently spoke with the glasses' product manager, Cassie Li, about the redesign and why DAQRI's latest should be considered for your plant's AR plans.

NED: The list of AR wearables to choose seems to grow daily. What do the DAQRI Smart Glasses do that others don't?

Cassie Li: We're focused on enterprise and very specific customers and we designed these smart glasses for professional grade AR. One thing that makes us better is we use a laptop processor. It's a lot more powerful than what's out there in the market. A lot of our customers have this complex data, they have these existing 3D models that are just huge, and require a lot of processing power to handle.

Every company wants to improve the way they do work, and the DAQRI Smart Glasses let you build visualize and interact with anything you want using AR. You can bring in massive 3D models, walk around them, and zoom in and out. When users try that on competing devices, it just lags. It goes back to is this solving the problems for the customers, and providing end-users in industrial facilities a product for their complex work tasks and to improve existing work.

NED: We got so excited about the Smart Helmet making this futuristic workplace that we may have lost sight on what's in it for industry right now. Do you think it was too much tech too soon?

CL: We start off by saying, "Let's paint this aspirational picture, let's paint what it could be." That's where we get into these situations where you think it's Iron Man –esque. I think we can get there. I don't know how long it will take, but I think it's important because it gets people excited. And it helps our road map in the current state, because if we want to get there, we have to know what we're aiming for. Imagine where you ultimately want to be and take baby steps to get there.

NED: What's one of the most beneficial use cases of the Smart Glasses today?

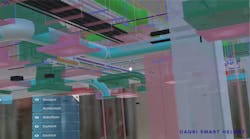

CL: In architecture and construction, you're trying to design this building, working in 2D on a computer, but building a 3D object. Now I want to see how it is at scale. Physically building costs a lot of money and time, and is limited to something like these 3D scale models a 16th of the full size. Now with this product, they don't have to go through that process If they have the 3D content, they can put it in these glasses and collaborate with other teams to do the visualization. Being able to walk through a building at full scale is so powerful. You can see a clash that is happening, which is harder to find on a computer.

That's actual value and why people will use it. Maybe it's not a Hollywood movie, but it is a step in making your life better. And we do want to make those other steps afterwards.

NED: What were some of the advantages and disadvantages of turning a helmet into glasses?

CL: The big points of feedback were the balance and weight. It was very heavy. We moved that weight off of your head and onto your hip, and use the same high end processor but divided it into a modular architecture. When you divide into two, you make the architecture a lot harder because now its two sub-products and you have to design the mechanical structures around that. We made it so you can plug the glasses directly into a computer without the Compute Pack, but that means the glasses on their own need to talk to it. All these pieces increase its complexity because you're trying to make it simpler for the end-user.

And workers in a factory, they don't normally wear a helmet, so we'd be changing what they do. The glasses actually made sense and opened up the market.

NED: The Smart Helmet also served as head protection. What are some of the safety aspects of the new glasses?

CL:They are [ANSI/ISEA Z87.1 and EN166] rated for eye and face protection. And we spent a lot of time working on the cable connecting the glasses to the Compute Pack. If the cable is a little loose, the display might not work and data might not get sent. It was super important that there was no wiggling, but there's the opposing side of the safety aspect. In a factory, there are regulations around if your hair gets caught in something, you have to have your hair up. What if this cable gets caught in the machinery? You'll get pulled in, so we have to make it detach at some level of a pull, but not wiggle. We reached that sweet spot with a permanent attachment to the bottom, but the cable is connected by a magnet at the top. With some pull, it comes off immediately so you're kept safe.

About the Author

John Hitch

Editor, Fleet Maintenance

John Hitch, based out of Cleveland, Ohio, is the editor of Fleet Maintenance, a B2B magazine that addresses the service needs for all commercial vehicle makes and models (Classes 1-8), ranging from shop management strategies to the latest tools to enhance uptime.

He previously wrote about equipment and fleet operations and management for FleetOwner, and prior to that, manufacturing and advanced technology for IndustryWeek and New Equipment Digest. He is an award-winning journalist and former sonar technician aboard a nuclear-powered submarine where he served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723).