Ergonomics Made Easy: Just Choose the Right Tilter

In material handling processes, unless your factory manager is Willy Wonka or Rube Goldberg, you want to keep things simple and easy. And of course, cost-effective (a.k.a. cheap).

With a pallet jack or lift table, that’s not a difficult proposition. There may be a few bells and whistles from model to model, but pallet jacks primarily transfer along a horizontal surface and lift tables up and down. When ordering these, it’s difficult to screw up.

In the case of container tilters, the process – angling a container or basket up to 90-deg. to make its contents more accessible—may be simple, but choosing the right one is not, says Jim Galante director of Business Development at Southworth Products.

Containers can be up to 30 x 40 X 40 in., so repetitively bending over to reach a product in the far bottom corner could cause some ergonomic issues.

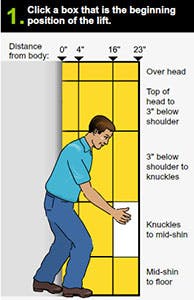

“Reaching out is worse than back bending. It puts more strain on the lower back than just bending over and picking up something at toes," says Galante, who is also chairman of the Ergonomics Assist Systems & Equipment council for the MHI. “Think of it as a jib crane, putting a huge lever arm onto your back.”

The weight, height, and distance, along with how much you must rotate your torso, greatly affect how much you can safely handle in a day.

Southworth has a catalog of 36 industrial tilters, from portable to stationary, electric to pneumatic. They also manufacture customized ones as well.

That’s just one company. It’s a broad field, and they are not all interchangeable.

“Misapplying equipment goes on every day in every industry, and this is an easy one to misapply,” explains Galante.

To assist you in making the right tilter choice, we asked the 47-year-year veteran of the supply chain gang to talk about the most important features to look for.

What Are the Dimensions?

The size and shape of a commonly used container can vary from 27 x 30 x 30 in. to 30 x 40 X 40 in., Galante says. Knowing the container size is the first step to getting the right tilter.

Also, if you have a flimsy container, such as a gaylord, you would also want to add a platen, a welded side plate that keeps the container secure on the loading base.

What Are You Putting in It?

"If you don’t pay attention to what’s in the container, you can get in trouble real quick," Galante says.

If you are loading mufflers that are standing vertical, it’s best for the hinge to be on the floor. If they are horizontal, a high hinge, which tilts at an axis about 30 in. off the floor, would make it easier to access.

When explaining this to his salespeople, Galante uses handling tennis balls as an example. For a basket full of loose tennis balls, a high hinge works because tennis balls tumble forward right to waist level. But for balls packed in boxes, they don’t want to tumble forward. In that case, having the container lower to the floor ends up being less stressful on a handler’s back.

Check out more of Southworth Products' ergonomic solutions.

What’s the Max Loaded Weight of Container?

The capacity can reach up to 4,000 lb., but Galante says even a load of metal bearings may only reach 3,000 lb. At the same time, you wouldn’t want to put a 3,000 lb. container on a tilter with a 1,000-lb. capacity.

A Penny Saved Is a Penny Lost

If you make your choice based solely on price, it could cost you in the long run.

“You can look in a catalog or go online and buy one for $1,500 and think it looks great,” Galante says. “You end up paying a lot more if it hurts someone or doesn’t offer a productivity advantage.”

The cheapest tilters on the market operate on a manual foot pump.

“If you’re going to load 10 baskets a day, and every basket gets jogged 5 times, you sure don’t want to use a foot pump,” Galante says. “The worker isn’t going to do it. He’s just going to bend over and do his job, and he’ll end up with a back injury.”

Portable or Fixed?

“In today’s factories, fork trucks are just not allowed in work stations,” Galante says. “If a fork truck tire hits a yellow line, someone could get in trouble.”

That’s a big reason why the portable tilter is Southworth’s most popular model. Just drop the container into the tilter and roll it over to load or unload the material.

They are powered by a 12V DC battery, which has a charge that lasts a few weeks to a month because they aren’t being cycled that much a day.

If you can load the container or basket with a pallet truck easily, and if an ac plug is near the workstation, you may prefer a stationary tilter.

About the Author

John Hitch

Editor, Fleet Maintenance

John Hitch, based out of Cleveland, Ohio, is the editor of Fleet Maintenance, a B2B magazine that addresses the service needs for all commercial vehicle makes and models (Classes 1-8), ranging from shop management strategies to the latest tools to enhance uptime.

He previously wrote about equipment and fleet operations and management for FleetOwner, and prior to that, manufacturing and advanced technology for IndustryWeek and New Equipment Digest. He is an award-winning journalist and former sonar technician aboard a nuclear-powered submarine where he served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723).