Ford and ExOne are Making a Material Difference

Manufacturing is at a bit of a crossroads. And while there is no one incident that has brought about the current need for action, it is undeniable that supply chains are tattered, and customer demands are shifting. It is time for businesses to make some tough choices.

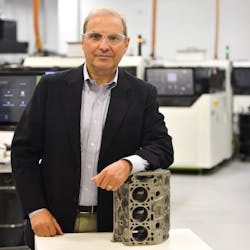

Strategic investments in additive manufacturing could help. “The supply chain became global to the benefit of consumers and the increasing the quality of life for a lot of people. But it's kind of gone a little far,” ExOne CEO John Hartner says. “There has been somewhat of a wake-up call recently combining tariff wars, the pandemic, incidents like the Suez Canal, as well as the awareness that local production, when done cost-effectively and sustainably, is more effective and more responsive to the consumer demand. This is especially true as demand has become increasingly customized and unique.”

The disruptions force people to pay attention to where technologies like additive fit, explains Hartner. "The next three to five years are going to be significant for additive to get enough validations that broaden adoption. Fortunately, the technology is really coming into its own," he says. "A dedication to material and process innovations can only help further its cause.”

Innovative commitment

Innovation is often the direct result of a commitment to finding better ways to solve existing problems. And having an interest in finding ways to leverage additive is nothing new to Ford Motor Co. The global automaker has been a long-time user and an early adopter of 3D printing, purchasing the third system ever made in the late 1980s. Its application of the technologies has progressed from simple visual prototypes—to prototypes that are robust enough for physical testing—to applications to support manufacturing operations—to now limited low volume production parts supporting the F-150 Raptor and the Shelby GT500 Mustang.

“We have several additive manufacturing facilities with professional-grade systems in North America and Europe that supply tens of thousands of parts each year. We have put systems in engineering environments and Maker Spaces all around the world to allow engineers hands-on learning and application development,” Harold Sears, additive manufacturing technical leader, Ford Motor Co. says. “We are expanding the use of these technologies into our manufacturing environments to support and enhance certain production processes. This has resulted in at least one printer in nearly every manufacturing facility around the world, with many facilities having more than one.”

According to Sears, Ford has also launched internal education programs for both UAW and salaried workforces to help them better understand these technologies and apply them efficiently and effectively. “We will continue to build on this foundation and explore the business value and value to our customers around opportunities to expand to more complex, higher volume and more physically demanding applications,” he says.

Collaborative output

The fruits of Ford's commitment to additive innovation shine bright when looking at the results of a project it co-funded with ExOne. The goal of the collaboration was to bring together a team of engineers, material scientists, and manufacturing experts to develop a new patent-pending process for rapid and reliable binder jet 3D printing and sintering of aluminum that delivers properties comparable to die casting.

The resulting process is expected to increase Ford’s efficiency by allowing the company to affordably produce complex parts uniquely designed for additive manufacturing which enables size and weight reductions, part consolidation, and performance improvements. The new innovation came about through the process of binder jetting, widely regarded as the fastest method of metal 3D printing for high-volume output. It uses a digital file to quickly inkjet a binder into a bed of powder particles such as metal, sand or ceramic to create a solid part, one thin layer at a time. When printing metals, the final bound metal part must be sintered in a furnace to fuse the particles together into a solid object. The heating process reinforces the strength and integrity of the metal, and while the process for sintering stainless steel is well understood, achieving high densities greater than 99 percent is an industry breakthrough for aluminum.

“This is a breakthrough in making 3D printed and sintered parts for the auto industry,” says Sears. “While the 3D-printing process is very different than stamping body panels, we understand the behavior of aluminum better today, as well as its value in light-weighting vehicles. High-speed aluminum 3D printing paves the way for other opportunities that we’re just now starting to take a look at because of the ability to do complex parts with aluminum that previously weren’t possible. It’s really opening doors for other opportunities.”

Although a very common material within the automotive industry using traditional production methods, 6061 is a material that has been difficult for additive because of its reactive nature. “However, with Ford's involvement, we have a customer who has real parts, who's done real metallurgy, and who's certified the materials and the microstructure to meet its stringent requirements,” says Hartner. “Developing a fast, affordable, and easy way to 3D print aluminum with traditional material properties is a critical step toward light-weighting more products and delivering a more sustainable future.”

Sears adds that material evaluations are extremely important regarding exploration and expansion of additional applications for 3D printing/additive manufacturing. “Automotive grade materials have been a challenge for the additive manufacturing industry. UV exposure, salts, fuels, solvents, etc. have limited applications,” says Sears. “We do not need materials that are exactly the same as materials used in traditional manufacturing; we need materials that are robust enough to qualify for our demanding applications and environments. As suitable materials become more available and as printing processes improve, more applications will be considered.”

Look ahead, Hartner is understandably encouraged by the progress. “We've got some great processes to scale the print and sinter process,” he says. “We wouldn't have announced something like this if we didn't have a line of sight to deliver this for high-volume applications. It is very encouraging to make progress on reactive materials.”

About the Author

Peter Fretty

Managing Editor

As a highly experienced journalist, Peter Fretty regularly covers advances in manufacturing, information technology, and software. He has written thousands of feature articles, cover stories, and white papers for an assortment of trade journals, business publications, and consumer magazines.