N-Ray is the New X-Ray: Making NDT More Accessible

Madison, Wisconsin has long been a hub for nuclear research in the Midwest. Some of the most cutting-edge nuclear research happening today is still centered in the heart of the Midwest, including the development of revolutionary new neutron sources for applications like industrial radiography. Phoenix, LLC., a nuclear technology company founded by University of Wisconsin-Madison alumni, has created the first system in history to provide neutron radiography for commercial use without relying on a fission reactor, instead applying cutting-edge accelerator technology. This will make neutron radiography, a powerful but seldom-used method for nondestructive testing (NDT), much more accessible to the NDT community.

What Is Neutron Radiography?

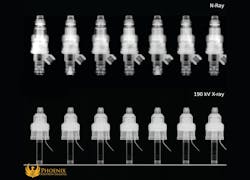

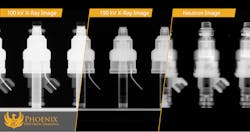

Neutron radiography, like X-ray imaging and other methods of industrial radiography, uses penetrating radiation to create a film or digital image of an object’s inner structure. Because neutron radiation has very different properties from X-rays and other types of radiation on the electromagnetic spectrum, it has many uses in niches where X-rays alone would fall short. For example, since neutrons penetrate denser materials more easily than lighter materials, neutron imaging is particularly handy for inspecting energetic devices such as ejection mechanisms and munitions, whose dense outer shells are often a struggle for X-rays to penetrate.

Neutrons behave quite differently than X-rays. With X-rays, the denser an atom is—i.e. the more electrons it has—the greater difficulty X-rays have passing through them. As a result, denser substances are more opaque than lighter materials, which is why, for example, an X-ray image of your hand shows your bones but not the surrounding flesh. For neutrons, there is no such simple correlation between density and opacity. In fact, even two elements placed right next to each other on the periodic table, which would look almost identical in an X-ray image, can appear completely different in a neutron image.

Neutron radiography has a wide range of uses in industrial NDT, such as detecting internal flaws in cast parts, showing defects in low-density and energetic materials, finding evidence of corrosion inside metal pipelines, inspecting welds for structural integrity, and identifying the presence and position of o-rings, seals, lubricants, and adhesives inside complex assemblies. However, due to its relative inaccessibility compared to other NDT methods, its full potential in many applications remains tragically underexplored.

The method of neutron radiography was first used in the 1930s soon after James Chadwick first discovered the neutron, but it didn’t start to see industrial use until the 1950s when research institutions began building and running fission reactors. Nuclear fission produces several distinct types of radiation out of the leftover subatomic particles that remain when an unstable atom breaks down into two or more smaller atoms: Alpha radiation, which consists of two protons and two neutrons bound together; beta radiation, which consists of free electrons; and neutron radiation, which consists of free neutrons. Neutron radiography requires a very high, sustained neutron output per square centimeter—in other words, a high neutron flux—in order to produce sharp, clear, and detailed images which up until now, such a high neutron flux was only achievable in these fission reactors.

As there are few reactors available for commercial use, this heavy reliance on reactors has severely restricted the use of this technique. Recently, the number of reactor facilities offering neutron radiography has also been decreasing as reactors age and are decommissioned.

The decreasing number of fission reactors that are available for neutron imaging is a particular threat to NDT niches that heavily rely on neutron radiography for quality assurance purposes, such as manufacturers of the turbine blades for jet engines. Because neutron radiography is the most reliable method for detecting certain highly dangerous flaws in these parts, the manufacturers must use it rigorously to test their products, and loss of access to their neutron radiography vendors—whether permanently, in the case of reactor closures, or temporarily, in the case of shutdowns for maintenance—wreaks havoc on their supply chain.

For example, Aerotest Operations, a reactor facility which was the primary neutron imaging source for the aerospace industry since the 1980s, had to shut down due to an unexpected licensing issue. This dramatically altered the neutron imaging market landscape and forced aerospace manufacturers to find alternative solutions or give up the valuable test method altogether in favor of less effective, more accessible methods. This event brought to light how vulnerable the aerospace supply chain was by relying on a small handful of reactors for a critical aspect of production. It was clear that a more accessible and relying source for neutron imaging was needed.

New Innovations in Neutron Sources

Since the 1930s, researchers have investigated many different sources of neutrons ranging from tube sources, table or desktop-sized devices which produce a low neutron output by fusing heavy isotopes of hydrogen; isotopic neutron emitters such as the synthetic isotope californium-252, which naturally emit neutron radiation as part of the radioactive decay process; and, of course, fission reactors, which produce massive amounts of neutron radiation as a byproduct of uranium-235 splitting into smaller radioactive isotopes.

Neutron radiation has many industrial and research uses, and not all applications require a high neutron output. For example, the oil and petroleum industry relies heavily on tube neutron sources for oil well logging. Neutron radiography does require a high and sustained neutron output over a given area, though, and as discussed above, reactor facilities are problematic in some ways—not the least of which being their dwindling numbers!

Fortunately, many new innovations in nuclear technology are offsetting the losses of our aging nuclear infrastructure, such as companies like NuScale and Oklo, which are designing compact fission reactors to advance carbon-free energy; SHINE Medical Technologies, which is developing a non-reactor source for medical radioisotopes crucial for lifesaving medical imaging procedures; and Phoenix, which designs high-flux neutron generators to offset the loss of reactor neutron sources for applications such as isotope production, neutron imaging, and radiation hardening that typically require reactors.

In recent years, neutron generators relying on this nuclear process have become much, much stronger. Last year, Phoenix and SHINE, two Wisconsin nuclear technology companies in Monona and Janesville, respectively, conducted a joint test and broke records for the highest sustained neutron yield from a fusion source, beating the previous record-holder set in the 1980s by over twenty-five percent.

The Future of Neutron Imaging

Shortly after the world record demonstration, Phoenix finished construction on the very first reactorless commercial neutron imaging facility, the Phoenix Neutron Imaging Center.

The facility utilizes a high energy ion beam and proprietary target to generate enough neutrons for high quality, high throughput neutron radiographs.

The facility has been operating commercially since April 2020. During that time the facility achieved the highest neutron imaging quality possible according to the ASTM standard and was qualified by several key aerospace manufacturers.

Neutron imaging, as a method for industrial NDT radiography, has more or less consistently lagged a few decades behind its X-ray. For example, standards for digital neutron imaging analogous to the existing standards for digital X-ray imaging are currently in development, whereas these same standards for X-rays have existed for decades. This is a consequence of the lag between the discovery of a technique and the technology needed to develop it to its full potential.

For example, even though medical and industrial professionals were immediately excited by the discovery of X-rays in the 1890s, it wasn’t until much later that X-ray generating technologies became powerful and cost-effective enough for the technique to become ubiquitous throughout these industries.

The slow demise of reactor neutron sources has been sad and painful for the world of neutron imaging, but the development of powerful accelerator-based sources represents a much-needed change in fortune for neutron radiography as seismic as the shift from unreliable Crookes tubes to hot cathode tubes were for X-ray imaging. Facilities such as the Phoenix Neutron Imaging Center are spearheading a bright future for neutron radiography as it traces the path traversed by X-ray decades prior, exploring new ways to make industrial parts and infrastructure safer and more reliable.