Is Industrial Edge Computing Right for Your Facility?

Edge devices such as smart sensors are increasingly prevalent in the industry. Edge computing allows the device data to be collected, analyzed, and stored locally, near the point of origin, reducing the volume of data transferred to on-premises or colocation data centers or in the cloud. This form of distributed computing reduces transfer time (latency) and storage costs, improves speed, and enhances data security and privacy.

Following are some examples of targeted edge applications and broader packaged edge solutions.

Condition and Level Monitoring

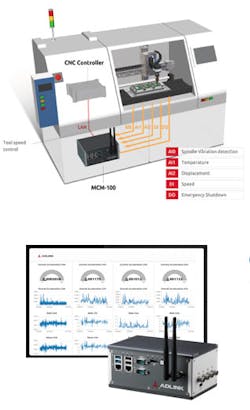

Addressing the challenge of unplanned downtime is the goal of Machine Condition Monitoring (MCM) Quick Start from ADLINK Technology. The MCM Quick Start kit consists of ADLINK hardware (MCM-100 Intel Atom x7-E3950 Processor-Based Machine Condition Monitoring Edge Platform) and software (ADLINK Edge), combined with SAS Event Stream Processing.

“These components combine to collect and analyze vibration data, providing real-time insight out of the box with a simple-to-use way of applying data science and AI to any CNC or other industrial machine, without the need for a large investment upfront,” says Cory Kress, sr. solutions architect at ADLINK Technology. “This way, customers can test the solution themselves prior to any larger-scale rollout.”

The 1030 Universal Smart Condition Monitoring System from Rexnord Process & Motion Control (PMC) is designed to support 24/7 remote monitoring of large gear drives. It continuously monitors the drives for vibration, oil quality, temperature, and relative humidity. It's one of the company’s Series 1000 Smart Condition Monitoring Systems, which are powered by the DiRXN Productivity Platform.

Available in kits to simplify system setup, each Series 1000 kit contains an edge device with smart technology that reads sensor values, computes the asset’s health condition, and triggers automated contextual alerts when abnormal conditions are detected.

An IIoT edge device for monitoring levels in tanks is the wireless and battery-powered Micropilot FWR30 cloud-connected radar level sensor from Endress+Hauser. Fitted with scalable digital services capabilities (Netilion Value, Netilion Inventory, SupplyCare Hosting), the sensor ensures reliable and remote-level monitoring as well as optimal process support for applications.

“End users quickly benefit from being able to access their information, data, and inventory status from anywhere and anytime through a secured and certified solution,” explains Ryan Williams, strategic business manager at Endress+Hauser. “They can make real-time, data-driven decisions to ensure process efficiency and cost savings.”

Service and Software Solutions

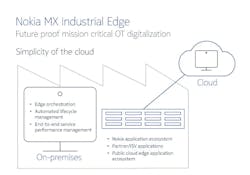

Edge computing solutions are being packaged to simplify adoption. MX Industrial Edge (MXIE) from Nokia is an on-premises edge solution designed to accelerate the digital transformation of industries’ operational technology (OT) environments.

“It combines the agility and simplicity of an edge-as-a-service model with a high-performance, resilient, and secure edge architecture designed to meet the mission-critical needs of asset-intensive industrial environments,” explains Stephan Litjens, vice president, Enterprise Solutions, Nokia Cloud and Network Services.

The “one-stop” industrial edge digitalization platform offers integrated features including industrial connectors to simplify IIoT complexity, device management, intelligent workflow automation, and the latest click-to-deploy applications for Industry 4.0 use cases, adds Litjens.

Amazon Web Services (AWS) offers Internet of Things (IoT) services and solutions, including AWS IoT for the Edge to bring cloud connectivity and intelligence to IoT edge devices. It enables computing close to the endpoints where the data is generated and allows data to be filtered at the edge to reduce cloud storage and cellular connectivity costs. Machine learning (ML) models developed in the cloud can be deployed to edge devices.

The use of AWS IoT services and AWS partner devices expedites the development and implementation of IoT projects. Using the same programming model for the cloud, on-premises infrastructure, and local devices provides a consistent experience across all environments along with edge-to-cloud security.

Project Cassini is Arm’s open, collaborative, standards-based initiative for delivering a seamless cloud-native software experience for devices based on Arm Cortex-A. It's helping organizations access “the power of the edge” by assuring developers of industrial solutions that a Project Cassini device will meet their fundamental requirements from day one of product development.

“In order for the industrial sector to realize an autonomous future, industrial edge solutions require high performance, real-time capability, security, and functional safety—all of which means software must easily and efficiently access the complete capabilities of the hardware it runs on,” explains Mohamed Awad, vice president of IoT and embedded at Arm.

Sheila Kennedy, CMRP, is a professional freelance writer specializing in industrial and technical topics. She established Additive Communications in 2003 to serve software, technology, and service providers in industries—such as manufacturing and utilities—and became a contributing editor and Technology Toolbox columnist for Plant Services in 2004. Prior to Additive Communications, she had 11 years of experience implementing industrial information systems. Kennedy earned her B.S. at Purdue University and her MBA at the University of Phoenix. She can be reached at [email protected].

Is Industrial Edge Computing Right for Your Facility? originally appeared on Plant Services, an Endeavor Busines Media partner site.

About the Author

Sheila Kennedy

CMRP & Owner – Additive Communications

Sheila Kennedy, CMRP, is a professional freelance writer specializing in industrial and technical topics. She established Additive Communications in 2003 to serve software, technology, and service providers in industries such as manufacturing and utilities, and became a contributing editor and Technology Toolbox columnist for Plant Services in 2004.

Prior to Additive Communications, she had 11 years of experience implementing industrial information systems. Kennedy earned her B.S. at Purdue University and her MBA at the University of Phoenix.