Carbon Unveils Flame-Retardant Resin for Automotive, Industrial Sectors

Carbon, a 3D printing technology company, has expanded the capabilities of its "idea-to-production" platform with the EPX 86FR, a flame retardant photopolymer resin with a dual-cure process, patented by Carbon.

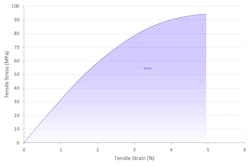

Carbon says the EPX 86FR offers an unmatched combination of flame retardance, functional toughness, high strength, and long-term stability. Additionally, it can help reduce development time and tooling costs for end-use parts, functional prototypes, and tools that require flame-retardant and self-extinguishing features, such as housings, brackets, and connectors in the automotive and industrial sectors.

“EPX 86FR was created for critical industries and markets that require a V-0 flame rating, high-performance mechanical properties, and smooth surface quality in a reliable, consistent, and high throughput printing platform.” — Jason Rolland, Senior VP of Materials - Carbon.

EPX 86FR is great for functional prototypes that require UL 94 V-0 or FAR 25.853(a) ratings with flame-retardant and self-extinguishing features by producing reliable surface quality, accuracy, and repeatability.

According to Carbon, the photopolymer resin works for applications such as electronic device battery housings, fans, circuit board covers, automotive battery cases, brackets, covers, fasteners, cable clips, and connectors.

Astoria Pacific, a manufacturer of automated analysis solutions for laboratories, uses EPX 86FR to develop heat bath housings for highly regulated electronics devices.

“We encountered significant supply chain delays in sourcing PVC and sheet metal,” said Whitney Menzel, Senior Engineer at Astoria Pacific.

“We turned to Carbon’s platform and extensive material lineup, including EPX 86FR, to mitigate these challenges. Not only did we experience a much shorter production time frame using the flame-retardant resin—from 18 weeks through traditional methods to 2 weeks using Carbon’s platform—but we also saw significant cost savings, enhanced surface finishes, reduced weight, and both thermal and mechanical advantages.”

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.