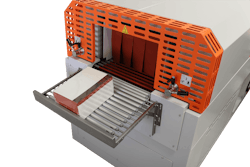

Clamco 250C Combo L-Bar Sealer and Tunnel Combination Shrink System

The 250C Combo L-Bar Sealer and Tunnel Combination Shrink System combines an L-bar sealer with a shrink tunnel in one robust, compact unit featuring a motorized closing seal bar arm that improves both operator ergonomics as well as production output. The power take-away conveyor quickly transitions product from the sealer to the tunnel.

The high flow digitally controlled 6,000-W tunnel effectively shrink wraps a range of products at a rate of up to 12 packs/min and measures 16 x 22 x 9 in. (406 x 559 x 229 mm). The machine has a welded steel frame and a 33-in. (838 mm) operating height. It features Pinwheel perforator wheels for rapid air escape for better shrink results.

This machine works with polyolefin up to 150 gauge and PVC up to 100 gauge. The film cradle can accommodate up to 20-in. (508 mm) wide centerfold film.

The L-bar sealer features on the 250C include a 17 x 23 in. (432 x 584 mm) seal area for shrink-wrapping a range of product sizes. A heavy-duty seal arm with motorized closing offers quick height adjustment to center the seal on the product.

Safety features include automatic cool down, seal arm obstruction detection, an easily accessible electrical cabinet, and locking casters for stable operation.

The 250C is replacing the now discontinued Clamco 120/240C Shrink System. PAC Machinery has stated that the 250C is being offered at the same price as its predecessor.

L-Bar Sealer Features:

- 17 x 23 in. (432 x 584 mm) seal area for shrink-wrapping

- Heavy-duty seal arm with motorized closing: push button or auto pace modes

- Quick height adjustment facilitates centering the seal on the product

- Heated seal blade

- Adjustable seal power

- Works with polyolefin up to 150 gauge and PVC up to 100 gauge

Shrink Tunnel Features:

- Tunnel chamber size: 16 x 22 x 9 in. (406 x 559 x 229 mm)

- 6,000-W heating power

- Digitally controlled tunnel temperature

- Heavy-duty blower with adjustable velocity and flow

- Tunnel conveyor with variable speed and live rollers (1.25 in. (32 mm) spacing)

- Insulated tunnel minimizes heat loss and maintains temperature consistency

Operating Features:

- User-friendly operator controls

- Film cradle accommodates up to 20-in. (508 mm) wide centerfold film

- Pinwheel perforator wheels for rapid air escape

- 20-in. (508 mm) long roller outfeed conveyor for package transfer at the end of the process

- Welded steel frame and 33-in. (838 mm) operating height

- Seal arm obstruction detection

- Automatic cool down

- Quick access to the entire electrical cabinet

- Meets CE requirements

- Locking casters

- Emergency stop button

Applications/Industries:

- Retail

- Beauty

- Home Goods

- Food, Meat, Cheese, Poultry, Fish

- E-Commerce

- Logistics

- Printing, Paper, Forms, Multi-Packs

- Records, CDs, DVDs

- Corrugated Boxes

- Books and Binding

| Seal Length End | 17 in. (432 mm) |

| Seal Length Side | 23 in. (584 mm) |

| Film Width | 20 in. (508 mm) Centerfold |

| Tunnel Opening Width | 16 in. (406 mm) |

| Tunnel Opening Height | 9 in. (559 mm) |

| Tunnel Inside Length | 22 in. (229 mm) |

| Tunnel Power | 6,000 W |

| Electrical Requirements | 220V, 50 amps, 1 phase |

| Overall Dimensions (L x W x H) | 9 x 3 x 4 ft (3 x 1 x 1 m) |

| Shipping Weight | ~ 1,650 lb. (748 kg) |

PAC Machinery