Shibuya Hoppmann to Showcase EP8 and FS-30 Feeders at PACK EXPO 2025

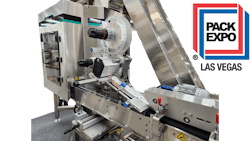

A manufacturer of aseptic filling and automation systems, Shibuya Hoppmann will display a complete feeding and labeling line at PACK EXPO Las Vegas 2025, Sept. 29–Oct. 1 (South Lower Hall Booth #12009). The system will demonstrate the EP8 Prefeeder paired with the FS-30 Feeder and an inline labeler applying labels to lip balm containers.

| EP8 | FS-30 | |

| Motor | AC | AC |

| Voltage | 230/460 | 230/460 |

| Horsepower | 1/4 | 1/3 |

| Weight | 720 lb (327 kg) | 450 lb (204 kg) |

The EP8 Elevating Prefeeder, built to handle medium-sized, lightweight parts of varying shapes, features a one-piece stainless steel hopper and cleated elevator belt, with 2-in cleat height and 6-in cleat pitch, delivering a steady flow of product to packaging lines to reduce downtime and maintain bowl feeder levels. A heavy-duty variable-speed motor provides an average belt speed of 32 ft/min. Designed for hygienic use, the unit includes FDA/USDA-approved 1-ply solid woven polyester belting with a 1/16-in PVC coating and PVC cleats. A hopper clean-out door enables quick access for maintenance. Its compact footprint allows installation in space-limited environments.

Operating downstream, the FS-30 centrifugal feeder uses urethane scallops to orient and deliver parts for labeling. Products are radially positioned in scallop pockets with the help of sweeps, wipers, and pneumatic or electric devices, depending on product requirements. The feeder is designed to accommodate a wide range of geometries and batch sizes while maintaining gentle handling.

The integrated inline labeler will demonstrate how the feeders can be combined for a continuous feeding and labeling process. Along with the demonstration system, visitors will be able to review Shibuya Hoppmann's broader automation portfolio, which includes modular systems that can be configured as individual units or integrated into complete lines to meet changing production needs.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.