What Are They Using in Warehouses?: Vision, AS/RS, and Packaging Automation in Use

CompControl Uses SVS-Vistek Vision Technology to Automate Incoming Electronic Goods Registration

Companies Involved: CompControl IT-Service und Vertriebs GmbH & SVS-Vistek

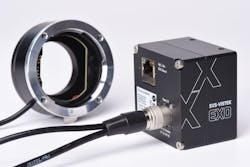

Product: SVS-Vistek exo342MGE Camera with SVS-EF Adapter

Electronics manufacturers often rely on manual processes to register incoming goods, leading to delays, data entry errors, and limited traceability. Existing automated systems frequently struggle to capture consistent data from the wide range of container sizes and heights used for electronic components.

To solve this problem, CompControl developed WEControlDOME, an automated incoming goods registration station built around SVS-Vistek machine vision technology. The system uses imaging rather than manual scanning to capture barcodes and plain text on incoming containers, extracting article numbers, quantities, batch numbers, and manufacturer information. This data is automatically verified against supplier records and posted to merchandise management and ERP systems, with optional labeling and photographic documentation.

At the core of WEControlDOME is the SVS-Vistek exo342MGE monochrome GigE camera, which provides 31.4 MP resolution for reliable barcode and text capture across varying container formats. To handle containers with different heights and geometries, CompControl integrated the SVS-Vistek SVS-EF adapter, enabling electronic focus and aperture control of Canon EF-mount lenses directly from the camera. This allows the system to automatically adjust imaging parameters without manual intervention or mechanical repositioning.

By using SVS-Vistek's camera and lens control technology, CompControl created a receiving system that adapts to variable inbound containers, reduces manual handling, and standardizes incoming goods documentation for electronics manufacturing operations.

SmartCap Uses PAC Strapping Automation to Standardize Packaging at U.S. Manufacturing Facility

Companies Involved: SmartCap (Fort Worth, TX) & PAC Strapping Products, Inc. (San Rafael, CA)

Products Used: PAC Strapping Automated Strapping Machines, including Top-Seal Strapping System

As part of its expansion into the U.S. market, SmartCap needed to address packaging consistency and labor challenges at its new Fort Worth, Texas, manufacturing facility. Manual strapping methods used previously led to variation in package quality and increased dependence on labor, an ongoing issue amid industry-wide workforce shortages.

To solve this, SmartCap worked with PAC Strapping Products to transition from manual to machine-based strapping. PAC evaluated SmartCap's packaging flow as products exited assembly and designed an automated strapping approach tailored to product size, weight, and packaging requirements.

PAC installed two automated strapping machines at separate stations to accommodate different product formats. For long, heavy cartons containing two stainless steel truck caps—often with imbalanced loads—SmartCap selected a PAC top-seal strapping machine using thicker polyester strapping. The system secures loads consistently and maintains package stability during handling and shipping.

By using PAC Strapping's automated equipment, SmartCap standardized its packaging process, reduced manual handling, and improved load security for large, high-value products. The machine-based approach also reduced worker exposure to manual strapping risks while supporting higher throughput and repeatable packaging quality across operations.

Scentsy Uses Dematic WES and AutoStore to Increase Fulfillment Throughput

Companies Involved: Scentsy & Dematic

Products Used: Dematic Warehouse Execution System (WES) & AutoStore Automated Storage and Retrieval System

Scentsy faced growing fulfillment pressure from increasing inventory volumes, frequent product launches, and rising e-commerce order demand. Its existing manual picking operation limited throughput and made it difficult to maintain speed and accuracy during peak periods.

To address these constraints, Scentsy upgraded its 160,000-square-foot Meridian, Idaho facility using Dematic's Warehouse Execution System software integrated with an AutoStore automated storage and retrieval system. The installation includes 20,800 storage bins, 100 R5 robots, 16 carousel picking ports, and two conveyor ports, supporting automated piece picking for e-commerce fulfillment.

Dematic's WES coordinates inventory movement, order release, and picking workflows across the AutoStore system and downstream operations. Orders are delivered to operators at goods-to-person picking ports and fed into a pick-to-cart process, reducing manual travel and handling.

The automated system increased Scentsy's picking capacity from 300 units per hour on its previous manual line to 450 units per hour. The solution also improves inventory density and consistency by consolidating storage within the AutoStore grid while maintaining steady processing speeds as demand fluctuates.

By using Dematic's software and AutoStore automation, Scentsy standardized fulfillment operations, increased throughput, and improved inventory visibility to support ongoing growth in its e-commerce business.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.