Fiber Optic Sensing is Seeing a Rise Across Pipeline, Concrete, and Subsea Applications

The use of distributed sensing (DS) is on the rise, especially for sensitive oil and gas and pipeline applications, structural health monitoring in concrete structures, and subsea cable infrastructure monitoring for offshore wind energy power sources.

DS enables precise monitoring that can benefit operators seeking to locate faults quickly to speed up repairs and reduce downtime. Equipped with robust connector systems that ensure data transmission when exposed to extreme pressures and temperatures, DS technologies are now poised to replace conventional monitoring devices.

Distributed Fiber Optic Sensing Basics

Distributed fiber optic sensing refers to technology that enables continuous, real-time measurements along the entire length of a fiber optic cable—unlike conventional monitoring devices, where a physical device is placed at the end of a copper line. A pulse of laser light is fired down the fiber and then the signals reflected back from various spots in the fiber are analyzed.[1]

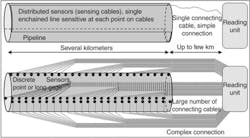

Figure 1 is an example of a fiber optics-based distributed temperature sensing system.

DS systems connect optoelectronic interrogators to an optical fiber (or cable), converting the fiber to an array of distributed sensors. The fiber becomes the sensor while the interrogator injects laser energy into the fiber and detects events along the fiber. Fiber optic sensing measures changes in the “backscattering” of light occurring in an optical fiber when the fiber encounters vibration, strain, or temperature change.

A key advantage of a DS cable is that it requires only one single connection to transmit the information to the reading unit, whereas other sensing technologies require connecting cables for each sensor, resulting in much more complex connections. DS sensors are also easier and less expensive to install and operate on large structures.[2]

Figure 2 shows the simple connections enabled by DS compared to the complex connections required with other sensing options.

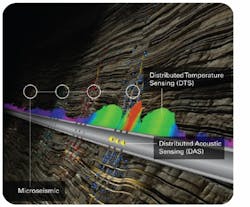

There are three key types of DS technology: distributed temperature sensing (DTS); distributed acoustic sensing (DAS); and distributed strain sensing (DSS).

DTS systems are optoelectronic devices that use Raman scatter from laser light pulsed through an optical fiber to observe temperature along a cable. Temperatures are recorded as a continuous profile along the entire optical sensor cable rather than at points, which results in extremely accurate temperature determination over great distances.

With DAS technology, a single fiber optic cable is used to detect acoustic energy and vibrations generated by activity around a cable. An artificial intelligence system analyzes the data and raises an alarm if it detects unwanted activity, warning operators of potential threats.

DAS can detect vibrations caused by threats, including electrical arcing caused by insulation breakdown and cable strikes caused by accidental excavation activities. The technology helps operators act quickly, which can greatly reduce costs through early warnings and targeted maintenance.

DSS technologies enable fiber optic cable to measure strain in structural and environmental monitoring applications over kilometer-long distances. Like DTS, the systems use Brillouin scatter to detect strain along the optical cable. This is relevant for defect identification, traffic monitoring, and vibration detection, which is especially useful for long concrete structures in remote locations.

Figure 3 shows how near-wellbore insight of DTS/DAS from fiber optics can be integrated with far-field insight from microseismic information.

DS in Sensitive Applications

In the past decade, the use of DS has been growing for a variety of sensitive applications.

Oil & Gas/Pipeline Applications

In pipeline integrity monitoring, DAS is being used to analyze real-time information on pipeline theft, leak detection, third-party interference, and damage and maintenance risks.

Over the past five years, fiber-optic sensing has been widely adopted for downhole monitoring. Improvements in glass chemistry, interrogation technologies, and analysis applications have resulted in robust downhole sensing technologies. With some technologies, as many as 20 fibers can be packed into a 0.25-inch tube (cable) that can be installed as a life-of-well monitoring system.

Each fiber can be turned into a fully distributed sensor for temperature (DTS), acoustics (DAS), and strain (DSS) measurements or used in multiple point sensors such as pressure gauges and geophones.

With new DS technology, oil and gas operators can now monitor the entire well simultaneously. They can see and hear things in a wellbore that were impossible with point sensors or wireline tools. In addition, since glass fiber is immune to electromagnetic radiation, it can transmit data at high speeds and can operate in extreme environments. The result is a technology that can benefit many well-monitoring scenarios.

Figure 4 shows the data available on a DAS data viewer. On the top is the acoustic amplitude; the bottom shows the frequency content.[1]

Fiber monitoring can also answer a multitude of questions posed by unconventional reservoirs without re-entering the wellbore, making it a very attractive option. Fiber-optic technology is being used for several well phases, including cementing, completion, real-time stimulation, post-stimulation, and production, as well as planning for the next drilling pad.

Concrete Structures

Another key application is the use of fiber optic sensing for structural health monitoring (SHM) in concrete structures. Here it can be used to confirm design assumptions, control the construction process, detect early deterioration, and detect structural failures.

Examples are installation on piles for vertical strain load; future monitoring for construction or natural hazards; horizontal load measuring; wall strain measurement in shafts due to differences in ground geography along the shaft depth; and temperature measurement to test for changes in deformation due to strain and temperature changes.[3]

Monitoring is a challenge with concrete structures, especially those in harsh environments and remote locations subject to long-term exposure to elements. Some lengthy structures such as pipelines and bridge span applications use DSS technology, in which cables are used to detect strain variation events. Here the fiber and jacket must be coupled tightly in a metal tube, with a cable that is more robust, but less sensitive. The cable may be integrated into the rebar in an internal installation, or it can be surface mounted for joint monitoring in dam systems where extreme temperature fluctuations may lead to joint failure.

Subsea Cables

DAS technology provides a monitoring platform for comprehensive and real-time visibility of the integrity of offshore subsea cable networks that play an important role in the up-and-coming wind energy sector. This enables operators to target repairs and conduct pre-emptive cable maintenance. With DAS, faults can be located down to very precise locations (down to 1 meter) to ensure less downtime and quicker repairs.

Subsea cables are designed to be in place for a long time; however, the seabed is a hostile environment. Even though cables are buried, seafloor currents can erode the seabed and expose cables, causing them to drift. This can result in strain and damage, which can ultimately cause fatigue-related cable breaks. Cables may also suffer electrical damage from arcing if the cable insulation fails. There is also the risk of accidental damage caused by a cable strike incident.

For example, in a case study prepared by Fotech, an international provider of advanced infrastructure monitoring technology, an offshore cable operator identified a fault in its cable infrastructure for an offshore wind farm. The operator used Fotech’s proprietary DAS technology to identify the fault and pinpoint its location so it could quickly conduct mitigation and repair activities.

The technology pinpoints activity down to just five meters, using optical fibers already present alongside power cables to detect vibrations caused by threats. The technology was connected to an optical fiber integrated inside the three-core subsea power cable, converting it into a highly sensitive acoustic and vibration sensor.

Fotech performed several tests to locate the fault on the cable; the DAS technology identified each response and pinpointed the fault to the precise spot on the optical fiber. They then correlated the location on the fiber with the geospatial location on the seabed by dropping an anchor near the fault. These impacts were detected and the impact locations were used to correlate with GPS data.

Divers could then zero in on the fault location and begin repair preparations. By precisely pinpointing the fault’s location, the operator minimized cutting to only 3.5 meters—allowing the cable to be repaired more quickly with only one joint and sufficient slack to avoid the need for adding a new cable section. Figure 5 illustrates the diver tapping on the cable and matching the location of the electrical fault.

In this case, the weather deteriorated immediately after the repair work had been completed. If the operator had used conventional fault finding and repair techniques, the repairs would have required a longer repair window, likely postponing them for at least another month. Using DAS technology saved millions in lost productivity, repair, and downtime.

Connectors Ensure Data Transmission Under Extremes

New optical connection systems are one of the key advances responsible for successes in using fiber optics for data transmission in extreme environments. These connections, combined with the precision-machined zirconia ferrule/alignment sleeve, ensure perfectly reproducible termini alignment.

One example is Green-Tweed’s Fiber Optic Extreme, originally designed for downhole oil drilling operations, which can withstand operating pressures of 25,000 psi and temperatures up to 347°F (175°C), as shown in Figure 6.

Greene-Tweed has also developed a variety of other fiber optic connectors for use in harsh environments. Made from high-quality, corrosion-resistant materials, connector systems include adapters, bulkhead feedthrough, fiber optic cable, patch cord and pigtail, assemblies, and dust caps. When used together, they provide a hermetically sealed connection protected from wet environments and particulates that can irreversibly degrade optical fiber.

Options are available for use in harsh environments where the assemblies are likely to be submerged in water or subject to rain, ice, high humidity, or temperatures from -55°C to 85°C (-67°F to 185°F). All connectors have passed stringent immersion and heat/humidity tests with minimal light loss.

Where Do We Go From Here?

Improvements in resolution and accuracy as well as new sending techniques mean that DS is likely to be even more valuable in the future. Just a few short years ago, obtaining a simple noise log was considered a great benefit. Now, many in the oil and gas industry are digging into the meaning of the data stream to examine the fluid density and other parameters.

An industry expert stated the following on the likely future value of the data: “Some of the value will be unlocked only when operators are able to cross-correlate these data with databases containing well bore, treatment, reservoir, and seismic information and models. Applying data analytics and parallel computing on a large scale is going to be the key to fully exploiting these strange, but exciting new diagnostic tools.”[1]

The value of the ability of the DAS to pick up and transmit data from other sensors is just now being understood. By packing a wide variety of sensors into a single, simple package, the operator can replace multiple conventional systems while reducing monitoring complexity and cost. In some instances, a completely new sensing technology can be added to the system by simply adding a new type of surface interrogator. This monitoring model has significant economic appeal in many applications, where many installations would quickly pay for themselves.

References

1. Fiber Optics Sensing Tools Move From Aerospace Research To Open New Frontiers In Fracturing, Glenn R. McColpin, Reproduced for Pinnacle, A Haliburton Service with permission from The American Oil & Gas Reporter, 2013.

2. Sensing solutions for assessing and monitoring pipeline systems, Sensor Technologies for Civil Infrastructures, B. Glisic, Volume 2 in Woodhead Publishing Series in Electronic and Optical Materials, 2014.

3. Notes from Fiber Optic Sensing Association seminar, Monitoring of Large Concrete Structures with Distributed Fiber Optic Sensing, 06/2021.

About the Author

Joseph Shih

Product Owner - Industrial Scientific

Joseph Shih is a former Technical Product Specialist for Greene Tweed, specifically for Seal-Connect.