SCARA Robots 2025: Compare the Latest Models for Speed, Load & Precision

What Is a SCARA Robot?

A SCARA robot (Selective Compliance Assembly Robot Arm) is a 4-axis industrial robot known for its high speed, horizontal movement, and rigid vertical axis. There are three rotational axes for horizontal motion (X-Y plane) and one axis for rigid vertical motion (Z plane), making it ideal for fast, repeatable tasks that require accuracy and minimal vertical deviation.

SCARA robots are known for short cycle times, compact footprints, easy integration, and payload capacities between 2 and 44 lb (1 and 20 kg), making them well-suited for short-reach, point-to-point applications.

Typical applications include small-part assembly, pick-and-place, screw driving, packaging & labeling, material handling, electronics production, medical device kitting, and vision-guided inspection.

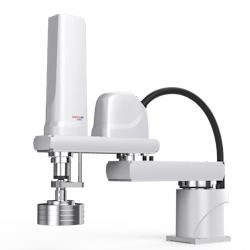

Epson Robots | GX-C Series SCARA Robots

Standouts: Compact, reliable, third-party applicable

Epson’s GX-C Series is the latest addition to its SCARA lineup, designed for high throughput, compact integration, and enhanced safety through SafeSense Collision Detection Technology, which allows users to remove physical safety barriers while maintaining speed and precision. The series includes the GX4C, GX8C, GX10C, and GX20C, all powered by the RC800A controller and available in multiple arm configurations to suit a range of reach and payload needs. Each model features GYROPLUS Vibration Reduction Technology for smooth motion and fast settling times, and runs on the Epson RC+ 8.0 platform with support for third-party automation tools.

Click Here to View Specs

| Payload | Up to 22 lb (10 kg) |

| Reach | 250 to 1,000 mm (9.8 in to 3 ft) |

| Repeatability | 0.001 to 0.025 mm |

| Max Cycle Time | ~0.28 to 0.42 s |

| Axes | 4 |

| Voltage |

AC 200 to 240V (single phase) |

| Power |

1.2 to 2.5 kVa |

| Weight |

33 to 121 lb (15 to 55 kg) |

| Movement Range |

105 to 152 degrees |

| Mounting |

Table, ceiling, or wall |

| Controller |

RC800A Controller & RC+ 8.0 platform |

What's Included

- GX-C robot

- RC800A controller

- E-Stop unit with cable and connector

- Cable with flying leads for controller

- E-stop/Safety connection

- Connector set (I/O, hand I/O and safety circuit connectors)

Optional Add-Ons

- Vision Guide

- IntelliFlex Feeders

- Force Guide

- Conveyor Tracking

- Epson RC+ API 8.0 R19NZ901JK

- GUI Builder 8.0 R19NZ901JQ

- Fieldbus Master Available

- Fieldbus Slave (Ethernet/IP, EtherCAT, PROFINET, PROFIBUS, CC-Link)

- External Control Point (ECP) 8.0 R19NZ901JL

- Teach Pendant Available

- Epson OPC UA for Robotics R19NZ901JZ

- Arm Length Calibration R19NZ901JW

- Bellows Kit (Standard and Long Z)

Target Applications

- Assembly

- Material handling

- Packaging

- Workcell operations

- Electronics

- Testing & inspection

- Cleanroom-compatible processes

- Washdown processes

Learn more: Epson's GX-C Series SCARA Robots

Topstar Technology | TRH10 & TRH15 SCARA Robots

Standouts: High-load capacity, fast cycle times, built for energy sectors

Topstar Technology's TRH Series SCARA robots are built for high-speed, high-load applications where precision and stability are critical. The TRH10 Series includes four models, while the TRH15 Series offers two, giving manufacturers flexibility based on application needs. Both series are designed to boost efficiency in demanding environments such as lithium battery production, photovoltaic manufacturing, and 3C electronics. Topstar reports that the TRH Series operates at least 20% faster than traditional robots, enabling higher throughput, shorter production times, and overall gains in operational efficiency. Typical applications include core making, assembly, and module PACK processes in battery lines; silicon wafer handling in solar production; and precise assembly, packaging, and labeling in electronics and medical manufacturing.

Click Here to View Specs

| Payload | 22 to 55 lb (10 to 25 kg) |

| Reach | 800 to 1,000 mm (2.6 to 3.2 ft) |

| Repeatability | 0.25 mm |

| Max Cycle Time | 0.39 to 0.48 s |

| Axes | 4 |

| Voltage | AC 220V, 50 Hz |

| Power | 2.2 to 2.4 kW |

| Weight | 108 to 128 lb (49 to 58 kg) |

| Movement Range | 132 to 360 degrees |

| Environment | IP20/1P54 |

What's Included

Topstar does not publicly list what's included with this purchase, so it may only cover the robot arm itself. We recommend clarifying package contents directly with Topstar or your distributor during procurement.Target Applications

- Lithium battery manufacturing

- Photovoltaics

- 3C Electronics

- Medical & Pharmaceutical

- General packaing & asssembly

Learn more: Topstar THR10 & THR15 SCARA Robots

Schneider Electric | Lexium SCARA Robot

Standouts: Ultra-compact, built-in-controller, integrates with other Schneider products

Schneider Electric's Lexium SCARA robot is a compact, high-speed automation solution designed to optimize floor space and boost production line efficiency across a wide range of industries. With a footprint 40% smaller than comparable SCARAs and an extended work area, it balances space savings with performance. The lineup includes six models, giving users flexibility to match the right reach and payload to their application. Each robot features integrated motors and a built-in controller to simplify installation, reduce wiring complexity, and minimize mounting and cabinet space. The Lexium SCARA also integrates seamlessly with Schneider’s EcoStruxure Machine Expert Twin platform, enabling unified control across multiple robotic systems—including SCARA, Delta, and Cartesian—while supporting virtual design and testing to help reduce capital and operational costs, avoid scheduling delays, and simplify deployment. The system is also designed for ease of use, eliminating the need for specialized robotics expertise and allowing for quick adjustments and configuration.

Click Here to View Specs

| Payload | 13 lb (6 kg) |

| Reach | 500 to 700 mm (1.6 to 2.2 ft) |

| Repeatability | 0.02 mm |

| Max Cycle Time | 0.4 s |

| Axes | 4 |

| Voltage | 170 to 250V AC |

| Power | 0.9 to 2 kW |

| Weight | 59 lb (27 kg) |

| Movement Range | 129 to 360 degrees |

| Mounting | Floor |

| Controller | LMC Eco/Pro2 motion controllers on a Sercos bus |

| Environment | IP20/IP65 |

| Certifications | CE Markings, UKCA Markings |

What's Included

Schneider doesn't publicly list what's included with the purchase. They do note that the gripper is not included and that customers will need to buy one from a specialist manufacturer. We recommend clarifying package contents directly with Schneider or your distributor during procurement.Optional Add-ons

- EcoStruxure Machine Expert software

- EcoStruxure Machine Expert Twin, Scalable Digital Twin software suite

- PacDrive LMC Eco/Pro2 Motion controllers

- Lexium 62 multiaxis servo drive and motors

- Modicon TM5 IP20 Modular I/O system

- Lexium T, P Delta 2 & Delta 3 robots for pick-and-place solutions

- Lexium cobot

- Lexium MC12 multicarrier system

- Lexium Cartesian robots: Portal axes, linear tables, cantilever axes, multiaxis systems

Target Applications

- Food & Beverage

- Life Sciences

- Battery manufacturing

- Electronics assembly

- Logistics

- Warehousing

Learn more: Schneider Electric Lexium SCARA robot series

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.