Day 2 of Game-Changing Product Launches at IMTS 2022!

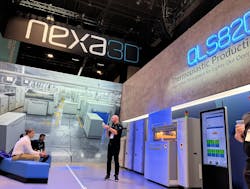

Nexa 3D

Now commercially available, the ultrafast laser sintering platform QLS 820 is designed for high throughput production with print speeds of up to 8 liters per hour and 20% packing density.

Nexa 3D says that the QLS 820 represents a new class of powder bed technology that combines ultrafast printing with open materials and a cloud software platform to deliver production volumes that are orders of magnitude greater than other powder-bed solutions on the market. The printer delivers a polymer-based production alternative to injection molding without the constraints, costly investments, and extended lead times.

NUM Group

Released a week ago, NUM presented its next-generation CNC platform, FlexiumPro for the first time live IMTS 2022 today.

Building off of its Flexium+ CNC system, NUM says it was able to significantly increase the computing power, speed, connectivity, and usability aspects of the FlexiumPro system by developing new concepts, new hardware, and new software compared to the Flexium+ system, among other things. The FlexiumPro system is more than 10 times faster and more scalable than the Flexium+ system, opening up new opportunities.

Both main processes, PLC and CNC, are now embedded and running together on a single board based on a multi-core ARM processor. The extremely high integration level, achieved by using System on Chip technology, results in a huge reduction of components which improves system reliability and availability.

Platinum Tooling Technologies, Inc.

Platinum Tooling announced it has added a new line to its products: Rineck Shrinkfit Tooling.

FactoryWiz Monitoring

FactoryWiz Monitoring released a sneak peek at its version 2023. FactoryWiz explains that this system collects activity status on assets such as CNC Machines, robots or assembly lines and presents real-time non-biased information for ethernet-connected factories. They claim the system helps to engage employees, spot trends as they happen, maximize production, and achieve lights-out manufacturing.

The new product will be available in the first quarter of 2023.

Mantle

Mantle, a Sanfrancisco-based 3D printer start-up, released two 3D Printers: The P-200 metal 3D printer and the F-200 sintering furnace. Another new 3D printer unveiled before the show was Mantle’s P-200. Mantle uses a process it calls "True Shape" which uses a paste extruder to precisely deposit a metal-rich layer. As the object is built, each layer is heated to remove binder and sinters the metal particles together, followed by a CNC milling action to smooth the surface.

Desktop Metal

FigurG15 is an all-new sheet metal forming technology that uses a patent-pending Digital Sheet Forming process to shape standard sheet metal on demand directly from a digital design file—no stamping tools, molds, dies or presses required. A software-driven ceramic tool on an XY gantry forms the sheet with up to 2,000 lb. of force in a highly engineered and proprietary build zone. Desktop Metal says that the platform can also process a wide variety of metals and sheet thicknesses.

Take a look at more product releases from IMTS 2022:

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.