Designed on the principles of lean manufacturing to reduce waste and improve workflow, robotic arc welding work cells can provide accuracy, reliability, versatility, and speed for many industrial applications spanning diverse industries.

While some manufacturers would argue the most efficient robotic work cell on the market is the one with the smallest footprint, there are other factors to consider. Which leads us to the question: what is the most efficient use of valuable floor space?

In order for manufacturers to gain maximum return on investment (ROI) over a given payback period, it is imperative to use the most efficient work cell possible for handling a given application and part type. Recent buying trends suggest that the purchase of a larger robotic work cell with additional robots can be a more productive solution for a company to increase throughput and improve product quality, fulfilling labor shortages and meeting customer demands in the process.

While many Asian-based manufacturers stress a robotic work cell with a small footprint is best, companies in the U.S. have generally been less concerned with floor space. This mentality is changing, however, as manufacturers seek to fulfill initiatives for increased productivity.

Yaskawa makes a variety of standard welding work cells, which are part of the ArcWorldseries. These cells can be used to illustrate six factors that contribute to floor space productivity. In turn, these factors can also help explain recent buying trends and evaluate the driving motivator for getting more productivity from factory floor space.

Six Key Factors to Consider:

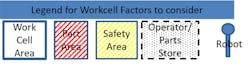

The answer to work cell efficiency may rest in comparing certain factors and reviewing simple ratios. To evaluate robotic work cell productivity, manufacturers should consider the following:- Part Area

The part area is simply the space that is needed to support a product. For example, an automotive seat supplier has an obvious size difference between recliner brackets, front seats, and 60/40 split rear seat frames for sub-assembly. Having enough part area to effectively and efficiently produce quality parts with tooling is key. Positioning the parts is also a factor. If the part needs to be re-oriented, it will need a larger three-dimensional volume. - Work Cell Area

This refers to the size of the entire work cell footprint, or how much floor space on the factory floor the robotic system encompasses. Manufacturers may view smaller cells as a more efficient use of floor space. While the footprint of the cell is a valid concern to consider, choosing a robotic system based on footprint alone is not ideal. Likewise, single-station work cells should be evaluated as a pair when comparing them to a two-station cell. - Safety Area

An open space, where an operator must vacate during positioner indexing to be compliant with safety regulations, is known as the safety area. Some manufacturers will customize a robotic work cell with roll-up doors to minimize the safety area space. Suspending part bins for smaller parts inside this area helps utilize this space and improve ergonomics. - Operator/Parts Storage Area

The operator area refers to the space where the operator grabs or places parts into the cell tooling. Cells with safety space can potentially crowd an operator with part storage, which would require a single station work cell to be equipped with a wider aisle. Single station work cells are sometimes placed opposing each other, so the operator loads one and then services the cell on the opposite side of the aisle. - Robot Quantity

The number of arc welding robots—or “arcs” referring to working torches—in a work cell is also paramount when choosing a robotic solution. Adding a second or third robot can nearly double or triple welding production with little to no impact on floor space. This is increasing the “arc density” of a given work cell. - Cost

The price of the work cell is considered at any stage of the design and implementation. Many times, the robot is a smaller percentage of the cost when positioners, cell controls, and tooling are included. Other items, such as laser sensors, could also increase cost but improve cycle time. A customer’s part and throughput requirements will dictate how much they may value these cost-adding features when creating an extremely efficient cell.

Application

When choosing the most productive work cell for a given application and part type, manufacturers should evaluate key factors that impact work cell efficiency as comparisons.For example:

- Part Area/Work Cell Area = Part to Work Cell Area Ratio

- Part/Work Cell X Arc Robot Quantity = Arc Density or Work Cell Productivity Ratio

- The Ratio of $ to Floor Space and # of Arcs = Value Ratio

- Integration Costs (1x per work cell): PLC +HMI + Power Drops + Tooling + Etc.

Example 1

A job shop or automotive company may consider the ArcWorld C-52 (AWC-52), which is a compact work cell for low to medium-volume fabrication that has two flat table stations (an AWC-52S has headstocks for turning parts). This cell delivers a powerful performance in a compact package, featuring:

- Reduced floor space

- One, six-axis Motoman robot

- Roll-up door

- Integrated welding package

- Max part size (millimeter) 760 x 700 capacity

Selecting a smaller work cell based on part size may appear to be the best use of floor space, but after considering the smaller part size in conjunction with the total footprint of the work cell, the overall area efficiency of this cell is only 12%.

In assessing the cell’s production capacity, the number of arc welding robots was evaluated as well. After calculating the part area to robot ratio and comparing it to the number of arcs, it was determined that the AWC-52 work cell productivity ratio was still 12% efficient due to the single robot.

Despite low entry cost, fast ramp-up time, tight footprint design, and easy safeguarding capabilities, this work cell may fall short for some manufacturers as comparisons are made.

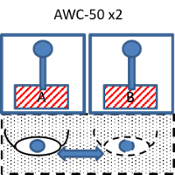

Similarly, compact, single-station work cells should be evaluated as a pair, compared to a two-station cell. This type of configuration adds an extra arc welding robot to the process, but also it adds more space to the operator area. While this work cell eliminates the sweep time of a positioner, it forces the operator to walk, offering poor ergonomics and potentially increasing cycle time.

Some manufacturers will locate these cells facing each other, where the operator space is tended by a single operator. This can drive the productivity ratio up to 30% based on two robots and the part/work cell area. The use of two cells will result in 2x the integration cost, which can be significant for automotive manufacturers with automated tooling.

Example 2

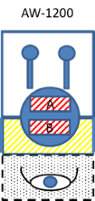

Manufacturers looking for a work cell to weld smaller parts that do not require positioning may consider the larger ArcWorld 1000 (single robot configuration) or ArcWorld 1200 (dual robot configuration). Pre-engineered for small- to medium-sized part production for medium-to high-volume welding applications, these ArcWorlds feature:

- High-speed servo turntable (60 or 72-inch tabletop)

- One or two, six-axis Motoman robots

- Functional Safety Unit (FSU)

- Integrated welding package

- Max part size (millimeter) 1,000 x 474 capacity

Using the same sub-assembly comparison (see Example 1), the AW1000 cell was found to be 10% efficient using the part area to work cell area ratio.

Despite the introduction of a high-speed servo turntable, the presence of the safety area created “dead space” that was unusable during operation. On the positive side, the operator area required minimal movement from the operator, creating better ergonomics.

When the arc density was calculated in relation to the part area to work cell area ratio, it revealed that the addition of an extra arc welding robot in this configuration (AW1200) increased the overall work cell productivity to 19%.

When comparing the list prices between other ArcWorld work cells, the AW1200 represents the lowest price/arc of all the work cells, making it a good value. There is only 1x integration cost for this cell.

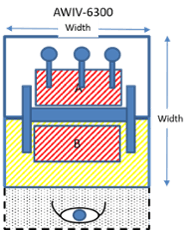

Example 3: Our most popular work cell, the AWIV-6000 series with ferris wheel positioner, provides the most efficient use of floor space. Pre-engineered for medium- to high-volume part production, these feature:

- High-speed capacity, space-saving, slim-line positioner

- One, two, three or four, six-axis Motoman robots

- Functional Safety Unit (FSU)

- Integrated welding package

- Max part size (millimeter) 4,000 and 1,525 capacity

Using the same floor space efficiency comparison (see Examples 1 and 2), the ArcWorld IV-6000 series cells were found to be 30 to 34% efficient using the part area to work cell area ratio. While the addition of a high-speed, slim-line positioner in relation to the part area and work cell area increased the efficiency of the cell, the presence of the safety area still created “dead space” that was unusable during operation. Some manufacturers have used roll-up curtains to span the safety area to reduce the distance used by light curtains.

As in the ArcWorld C-series and ArcWorld 1000 series work cell examples, the presence of arc welding robots boosted the productivity factor of each cell. When the arc density was calculated in relation to the part area to work cell area ratio for each cell in the ArcWorld IV-6000 series, the findings were as follows:

- AWIV-6000SL part area/work cell X 1 arc robot = 60% productivity ratio

- AWIV-6200SL part area/work cell X 2 arc robots = 67% productivity ratio

- AWIV-6300SL part area/work cell X 3 arc robots = 100% productivity ratio

The arc density in relation to the part area to work cell ratio gave the ArcWorld IV-6300SL a greater percentage, making it the most flexible and productive work cell in our standard configurations.

A repeat customer has changed from specifying AWIV-6300 cells with 3 robots and 3-meter positioner spans to cells with four robots (AWIV-6400) and 4-meter positioner spans. Although this slightly improves the customer’s part area to cell area (floorspace efficiency) from 34% to only 36%, the arc density ratio (or productivity efficiency) increases greatly from 101 to 143%. In addition, adding more robots is a cost-effective solution because cell integration costs, such as PLCs, HMIs, tooling, safeguarding, and utility drops, do not increase.

Conclusion

Compact robotic work cells offer a reduced footprint, but they are not necessarily the most efficient use of floor space. Job shops may want to evaluate the part size capacity in relation to the work cell footprint to determine the most flexible use of floor space.Moreover, in an effort to increase the productivity of floorspace, automotive companies may want to consider expanding the work area slightly to add more robots. Evaluating the cost of a couple, different work cell configurations, including integration costs, can help manufacturers make sure they are maximizing the value of their floor space.