Vibration Analysis: A Powerful Tool to Prevent Recurring Equipment Failures

A lot of the time, vibration issues don't make themselves known until something goes wrong. You might hear an odd noise, see premature wear on a coupling, premature bearing failure, or get a complaint from someone working near the equipment. By that point, you're already behind. From where I sit, in the field of failure analysis and root cause investigation, I can tell you: the costs of waiting are high.

That's why vibration analysis is such a powerful tool. It lets us monitor the machine while it's still working and catch problems before they become costly. Whether it's imbalance, misalignment, resonance, or wear, these issues have signatures. If you know what to look for, you can prevent a lot of pain.

I've spent more than 30 years working in marine and industrial environments—places where equipment needs to perform reliably, often in harsh conditions. Vibration analysis is one of the few diagnostic tools I trust to give early, actionable insight. And when we combine it with simulation tools like FEA (finite element analysis), we can do even more. We can design out the problems before they ever make it to the field.

Seeing the Problem Before It Happens—and Preventing It from Happening Again

All machines vibrate. That's normal. But when those vibrations change, or start to appear in the wrong frequencies, or increase in amplitude, those are signs that something's off. It could be a bearing starting to wear, or a rotating shaft that's slightly out of balance. Left unchecked, those small issues become big issues.

With the right sensors, we can measure vibration in three dimensions and watch how it evolves over time. If something changes, we can intervene early. It doesn't just help with breakdowns—sometimes it flags the issues behind excessive noise, fatigue cracking, or surface wear. These aren't headline failures, but they still generate customer complaints and long-term costs.

Want a deeper look at vibrations in rotating equipment? Expand below to see full details on synchronous, sub-synchronous, harmonic, and non-synchronous vibrations.

Click here to read more

Rotating Equipment Vibrations

While vibrations can be caused by many factors—the environment, operational conditions, natural phenomena, or external input—they're commonly associated with rotating equipment. By rotating equipment, we mean engines, pumps, compressors, fans, and any equipment which had an internal element that spins. For this discussion, the term 'element' will be any object attached to the shaft within the equipment that fulfills the equipment's function. Vibration in rotating equipment has been extensively studied, mostly because it's so common and because it's readily reproduced. Vibrations from a rotating element can be classed into different overlapping categories:

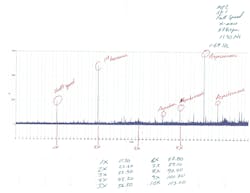

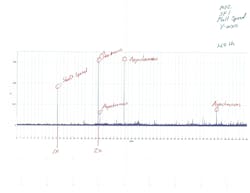

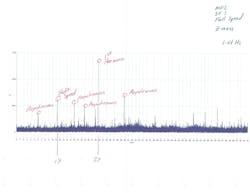

Synchronous Vibrations

Synchronous vibrations occur at the rotational speed of the equipment's shaft, expressed as rotations per minute (RPM). These appear in vibration analysis as amplitude peaks at the operating speed of the equipment or discrete multiples of that speed (1, 2, 3x the RPM). Synchronous vibrations are caused by problems with loads—unbalanced elements, eccentric elements, an unbalanced overhung load, uneven gear loading, or misaligned drive belts—or with the rotating shaft—bent shaft, offset shaft alignment, angular shaft misalignment, or a 'cocked', misaligned bearing. Vibrations from unbalanced overhung loads, uneven gear loadings, and misaligned drive belts can look the same—they're loads from the outside driving the shaft, which are causing fluctuations at the driven speed of the equipment.

Sub-Synchronous Vibrations

Sub-synchronous vibrations occur at fractions of the equipment's driven RPM. These appear at discrete fractions (1/2, 1/3, 1/4x the RPM) of the shaft speed—though mostly commonly at even fractions (1/2, 1/4, 1/8...) of the shaft speed. Causes for sub-synchronous vibrations include rubbing in the equipment, improper gear meshing, pole passing (in electric motors), belt natural frequency vibration (belt-driven equipment), or lubrication faults.

Harmonic Vibrations

Harmonic vibrations are a superset of synchronous and sub-synchronous vibrations. Harmonic simply means the vibration occurs at intervals which coincide with either a driven speed or the natural frequency of the object, or some multiple of that speed. Some other causes of harmonic vibrations can be the blade passing frequency for fans and pumps, or damage to a rotor bar in electric motors.

Non-Synchronous Vibrations

Non-synchronous vibrations have amplitude peaks that do not coincide with the RPM of the equipment or some multiple of that speed. Non-synchronous vibrations are often hard to find—the harmonic vibrations usually have large, distinct amplitudes, whereas non-synchronous vibrations can be diffuse and with smaller amplitudes. Causes of non-synchronous vibrations include the excitation of the natural frequency of an element, electrical line frequency (for AC motors), SCR frequency (for DC motors), turbulent flow or cavitation, the electrical pole passing frequency, drive belt frequency, and lubrication problems. It can also be problems with roller (anti-friction) bearings—fretting of the race, local overloading, out-of-round rolling elements, cage damage, or incorrect pre-load.

Radial Vibrations

When the vibration amplitudes are oriented horizontally and/or vertically relative to the axis of the shaft, then the cause is radial in orientation. Causes which show up as radial vibrations are all acting somehow to cause the shaft to vibrate out-of-plane—unbalanced elements, eccentric elements, rubbing, offset alignment, and belt natural frequencies can be considered.

Axial Vibrations

When the vibration amplitudes are oriented along the axis of the shaft, then the cause is axial in orientation. Causes that show up as axial vibration are acting in a way to cause the shaft to vibrate along its axis—misaligned bearings, angular misalignment, a bent shaft, misaligned drive belts, and an unbalanced overhung load will exhibit axial vibrations. If the vibrations are only axial, these are the main causes. Often, though, these will also manifest some degree of radial vibration.

When analyzing vibrations, it's important to make sure all possible vibrations are captured by using multiaxis accelerometers or accelerometers oriented in each axis. Ignoring an axis because that's not how the vibration seems to be acting can mislead the investigator. It's equally as important to examine the equipment before a vibration analysis so that one, the monitoring sensors are placed in an appropriate location, and two, the investigator can visualize the potential areas of concern.

Designing and Installing Equipment to Prevent Vibration Problems From the Start

Vibration problems don't just come from age or wear. Some of the most frustrating ones are baked in from the start. A poorly designed base, a support structure that resonates, or even a bolt that's torqued unevenly can create long-term issues.

That's where FEA comes in as a foundational part of a vibration analysis strategy. We use it to model how equipment behaves under load and predict where vibration might become a problem. FEA doesn't just show where structures might flex—it also highlights where natural frequencies may align with operating speeds, which is a recipe for trouble. We can simulate the stresses due to vibrational loads and adjust the design before anything is ever built. FEA is a complement to vibrational studies as it can point to inherent interactions that the vibration studies pick up.

After installation, vibration monitoring is like a sanity check. I've had cases where everything looked good on paper, but the vibration data told a different story. We tracked down foundation issues and installation misalignments that would've cost a lot more if we caught them later.

Designing for vibration can save costs and headaches. Expand below to see expert guidance on natural frequencies, harmonics, bearing selection, and mounting strategies.

Click here to read more

Designing Around Vibrations

When designing new rotating equipment, a new facility with rotating equipment, or installing new rotating equipment in an existing facility, being cognizant of potential vibrations can pay off with lower operating costs. I emphasize rotating equipment because it's often the action of a shaft, fan, wheel, pump, or other spinning element that induces vibration. That act of spinning—or rather, the spinning action of the element—is where imbalance, misalignment, offset loading, and other imperfections become unwanted vibrations. To prevent those imperfections from becoming maintenance headaches, the designer should be aware of a few critical concepts about rotating equipment:

Natural Frequencies and Harmonics

I'm about to make an audacious statement: All things vibrate at a certain frequency. Even a blade of grass, held in the gas between your thumbs, will vibrate if blown on with the right velocity of air. This is a Natural Frequency, the number of oscillations in a second that something will inherently vibrate at. It's crucial to know the natural frequencies—not only of the designed system but also what the system is mounted to—to not accidentally excite a response in something unrelated to the installation. For beams, plates, and other structures, derivative equations from the stresses and strains can be used to find the natural frequencies. For more complex assemblies, Finite Element Analysis programs commonly have Eigenvalue functions for the fundamental frequencies.

Harmonics are when some forcing function—say, an out-of-balance fan—excites a natural frequency of something else. The lowest natural frequency, known as the first harmonic, is the easiest to force into response; it takes the lowest energy to excite, and the response has the highest magnitude. Note, though, the frequency of the forcing function does not have to be at the first harmonic; it could be a multiple of the first harmonic.

Bearing Selection

Rotating equipment, to last for any amount of time, needs to be supported on bearings. The types of bearings are as varied as the applications—hydrodynamic bearings, sleeve bearings, rotating element ('anti-friction') bearings, and even magnetic bearings. Each has its advantages and disadvantages, which are beyond the scope of this article. The choice of bearing and bearing mount is another crucial aspect of designing around vibrations. Ideally, any two sets of bearings should be precisely aligned. Inside a machine, it can be done fairly simply—make sure the case or body is rigid and the bearing mounts are concentric.

Once the bearing mounts are no longer integral to the housing, then alignment is more problematic. A plain bearing in a misaligned mount is subject to a number of failure modes that result in vibrations. Consider self-aligning or spherical bearings when using pillow blocks in equipment.

Mounting

When mounting equipment, it can be critical to ensure the mount is suitable for the equipment and for the foundation. Rubber pads, blocks, and cones have been used to dampen higher frequencies from equipment into a foundation. For lower frequencies, consider springs or wire coils to dampen the greater amplitude generated by low frequencies. For many applications, such as large engines and forming machinery, damping vibrations is not possible because of the rigid support this equipment needs. It becomes part of the design to make a very rigid foundation with a high first harmonic and use a bedding compound to ensure full contact between the machinery and the foundation.

Lastly, be aware that your design may be subject to field modifications. A good example can be a ship's masts; I have seen masts intended to support only small (less than 100 lb [50 kg]) antennas, which have large walking surfaces for ease of access—just right for adding a 350 lb (150 kg) satellite antenna! What you end up with is an inverted pendulum, imparting extra motions into the satellite antenna at very low frequency.

Real-World Results

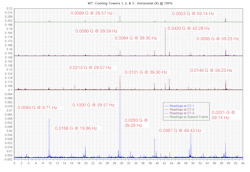

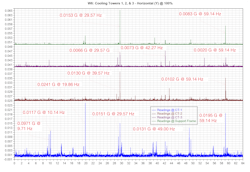

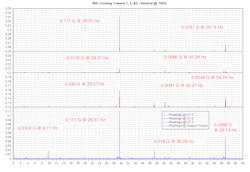

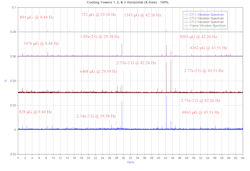

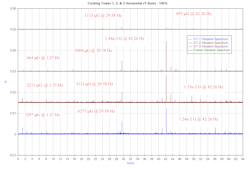

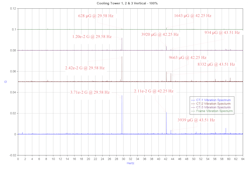

Vibration analysis is being used across industries to catch problems early and support smarter maintenance decisions. In my own experience, I worked on a case involving three evaporative coolers mounted on the roof of a municipal building where noise was inhibiting the use of meeting rooms. A vibrational analysis of their foundation indicated excessive vibrations in the audible frequency range were present in the vertical and lateral axes. Corrective action of adding more compliant mounting under the coolers resolved the vibrations by damping out the frequencies to a tolerable level.

I had another case where an industrial fan was generating excessive noise and showed signs of uneven wear. Through vibration analysis, we traced the issue to an imbalance in one of the fan blades, which in turn was causing resonance in the support structure. After rebalancing, performance normalized and the risk of long-term fatigue damage was minimized.

I have used vibration analysis to pinpoint where the structural support of satellite antennas on ships amplifies the fundamental frequencies of ship motion. While these motions would not affect the tracking of the antennas, they reacted with the antenna isolation system to damage the structure of the antennas. By reducing the compliance of the support, these low frequencies could be damped out, so the isolation system would absorb the higher frequency fundamentals.

These firsthand examples underscore just how varied and practical vibration analysis can be across equipment types and industries. Take semiconductor manufacturing, for instance. Vibration monitoring plays a key role in keeping motion stages operating with tight precision. If those stages start to drift or chatter, you're looking at lost accuracy and lost time. By tracking vibrations early, you can catch problems before they take a toll on throughput or bring the line down altogether.

In heavier industries, like steel mills, the stakes are different but just as high. Equipment like conveyors and crushers sees a lot of abuse, and if there's a resonance issue or some harmonic frequency that doesn't belong, it can quietly start tearing things apart. These are the kinds of problems that don’t always show up in a routine inspection, but vibration analysis will pick them up before they lead to major failures or shutdowns.

What's important here is that this kind of analysis isn't just for one niche. Whether it's precision manufacturing or heavy infrastructure, vibration data gives you an early warning system. And when you use it right, you're not just avoiding damage—you're extending the life of your equipment and cutting down on those surprise maintenance costs. That's a win for both operations and the bottom line.

The Technology Is Catching Up

The tools we have now are far better than what we had 10 years ago. Machine learning can pick up on patterns humans might miss. Cloud platforms let teams share and compare data across multiple sites. Tri-axial MEMS sensors allow small monitoring packages to be installed where previously we needed multiple piezo-electric accelerometers to measure all axes of vibration. What's really shifting is how vibration analysis is being used. It's no longer just about condition monitoring or reacting to problems after the fact. It's something we use to manage risk more intelligently and make proactive decisions before issues turn into failures. That shift has real value, especially when you’re looking to improve reliability and extend equipment life.

That is why the market for vibration analysis and predictive maintenance is growing quickly. Vibration monitoring applications are expected to hit revenues of $2.91 billion by 2030. And predictive maintenance overall? It's projected to reach $71.2 billion by 2032. That tells me companies are starting to see the value in doing things before they break.

Vibration problems don't always destroy equipment. But they often show up in the form of unexpected downtime, warranty claims, or unhappy customers—all of which carry their own price tag.

We can't keep waiting for failures to tell us what went wrong. With the tools we have today, we don't have to.

About the Author

Steven M. Lindholm, P.E., P.M.P., NAMS-CMS

Consulting Engineer

Steven M. Lindholm P.E., P.M.P., NAMS-CMS, is a consulting engineer and assistant vice president at Engineering Design & Testing Corp. With over 40 years of experience in mechanical and marine engineering, Steve specializes in finite element analysis, failure investigations, and structural assessments. Being EDT's naval architect and marine engineer allows Mr. Lindholm to return to his roots while indulging a passion for consulting with EDT’s clients who specialize in ship, marine and cargo incidents.

From the Oakland District office, Mr. Lindholm consults on inspection, evaluation, and design analysis of ship construction; stability; propulsion and auxiliaries condition assessment; ballast water treatment systems; vibrational analyses; and ship motion. He interprets and applies international (International Maritime Organization (IMO), class society, and flag state), United States Coast Guard (USCG/CFR), and regional regulations/guidelines to maritime casualties.

Mr. Lindholm explores root cause investigation and analysis of mechanical damage to equipment, components, and materials, including fracture analysis and failure analysis, and prepares repair and replace cost estimates for marine, industrial, commercial, and residential systems. He applies the principles of project management to monitor the workflow of repair/reconstruction activities. Mr. Lindholm also has experience in the design and evaluation of photovoltaic systems.