Case Study: Craft Brewers Update Canning Lines

More and more, canning is becoming the way craft breweries are getting their beer in the hands of customers. When it comes to canning technology, Pneumatic Scale Angelus (PSA)—one of the companies represented in Barry-Wehmiller Packaging Systems—has been a world leader for 100-plus years, with more than 16,000 installations in 132 countries.

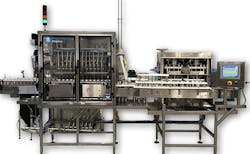

Last year at the Brewers Association Craft Brewers Conference and BrewExpo America, PSA debuted its CB50 canning line fillerseamer combo. Breweries such as New Realm Brewing Company, Crooked Stave Artisan Beer Project, Market Garden Brewery and Port Orleans Brewing Co., to name a few, have already installed the CB50 and are producing great canned beer for distribution and

onsite sales.

Due to demand for a higher-speed version of the CB50, at this year’s Craft Brewers Conference, PSA is introducing the CB100, which is capable of a variable speed range of 30 to 100 cans per minute.

“If you’re looking to upgrade the technology and speed from your introductory canning line, or if you’re a larger brewery looking to enter into the canning market for the first time, this is the line you need,” said Adam Brandt, Vice President of Sales for PSA.

One brewery that has already jumped on the chance to purchase a CB100 is Baltimore’s Heavy Seas Beer.

"Heavy Seas Beer is experiencing rapid growth for Loose Cannon and other Cannon Crew brands in cans, and we needed a solution that would provide greater speed and high quality,” said Dan Kopman, CEO of Heavy Seas Beer.

The CB100 has many of the same features as the CB50, but for a high-speed canning line. The integrated 12-head hygienic inline filler, with proprietary flowmeter technology, helps brewers get a perfect fill with little waste. The CB100 gas flush systems help keep oxygen out of the beer. And, PSA’s high-speed, industry-leading double-seaming technology helps keep cans sealed tight. The

integrated system is optimized for a beverage can-height range of 2.13 to 8 inches, and is designed with quick-change adjustments for easy changeovers for various can heights and body diameters.

“I was already very familiar with Angelus seamers,” Kopman said. “With that name, we knew we would get great technology. Working with the team on the delivery of our beer to the filler, and the filler itself, has given us real confidence moving forward as we commission the new line."

About the Author

Pneumatic Scale Angelus

A Barry-Wehmiller Packaging Systems company, Pneumatic Scale Angelus maintains a major market position in the supply of wet and dry fillers, cappers, can seamers, labelers, centrifuges and change parts for the pharmaceutical, personal care, food, beverage, canning and household products industries worldwide. Our custom-engineered product lines include Hema, Mateer and Pneumatic Scale fillers; Consolidated, Pneumatic Scale and TC cappers; Angelus and Closetech seamers; Burt and MTS labelers; Carr and Centritech centrifuges; onTrack orienters and wet-case detectors; and Zepf change parts and storage solutions. For more, go to psangelus.com.