Preventing Seams and Head Bursts in Threaded Metal Fasteners

Split heads and head bursts on threaded metal fasteners are classified as “surface discontinuities.” As such, they fall under the jurisdiction of quality standards such as ASTM F788/788M and SAE J1061. These and similar standards use the same criteria to classify and specify allowable limits of surface discontinuities that occur while manufacturing and processing bolts, screws, studs, and other types of externally threaded fasteners. Although these standards do not specifically refer to rivets, they are also applicable to rivets.

Splits and bursts within allowable limits do not degrade a fastener’s fit, function, or mechanical properties. Consequently, they are evaluated based on visual characteristics and aesthetic considerations. Visual criteria are often negotiated between manufacturers and customers based on the limits established in the aforementioned standards. Only in extreme cases that far exceed allowable limits will splits and bursts affect the fit and function, or degrade a fastener’s mechanical properties.

Definitions and Root Causes

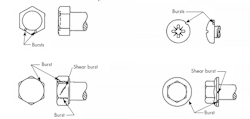

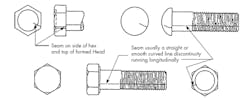

Bursts and Shear Bursts

A burst is an open break on the flats or corners of the fastener’s head or at the periphery of a flanged or round headed fastener. They are created during heading. A shear burst is an open break in the fastener’s surface at approximately 45 deg. to the faster’s axis, and usually located on the periphery of fasteners with flanged or circular heads or on the side of hex heads.

Bursts and shear bursts are typically caused by metals that lack the necessary ductility for a given upset ratio during heading. Bursts can also be caused by impurities in the material, such as inclusions.

A seam is a straight or smooth-curved-line surface discontinuity running longitudinally on the fastener’s body and head. It is created when the cast billet is rolled into a rod and the billet contains a subsurface inclusion or void that becomes elongated during rolling. Seams can also split open in locations of greater metal flow, such as at the head or at periphery of flanged or round headed fasteners.

Impurities that cause seams result from several different events during steelmaking. This makes prevention complex for large-scale steel manufacturing processes. Through years of trial and error, steel manufacturers have learned how to reduce inclusions and impurities. Some of these techniques include selecting the right steel charge, better control of casting temperatures, ladle stirring, modifications to the designs of the tundish and nozzle, and close control of cooling rate. However, antiquated melting/casting infrastructure and machinery make it next to impossible to eliminate the problem. Clean steel practices are achievable in newer steel foundry and casting facilities. However, even with advances in clean steelmaking, seams and split heads have not been completely eliminated by fastener manufacturers.

Prevention and Detection

There are several methods employed by steel manufacturers to minimize impurities and inclusions in steel and to help detect seams after rolling. Some of these techniques include:

- Ladle and tundish stirring during billet casting.

- Modification of the tundish discharge nozzle design for billet casting.

- Electromagnetic stirring (EMS) in continuous casters.

- Billet scarfing and surface preparation before rolling.

- Eddy current sensors located in rolling stands.

- Upset testing of coil. This is merely a sampling of the front and back ends of a coil after it has been rolled.

There are no foolproof prevention methods fastener manufacturers can use to eliminate splits and head bursts. However, there are a few measures that mitigate the risk of them occurring or reduce the severity of the cracks. These include:

Work closely with steel suppliers to control source and quality of billets and rolled products for critical parts. Fastener manufacturers don’t typically control the source of continuously cast steel billets used to supply them steel rod and wire. A rolling mill or outside processor may use steel billets from different sources to meet the same client specifications.

Upset testing. This is merely a sampling of the front and back ends of a coil after it has been rolled. It offers no guarantee, but can be useful if performed systematically.

Limit the pre-heading draw of the rod to a 10% reduction in diameter.

Lower the upset ratio during head-forming blows. This might require an increase in the number of blows by moving complex parts to multiple station machines.

Use spheroidize anneal at finish size (SAFS) steel rod.

Use lower carbon steel as permitted by product specifications.

Methods for detecting head bursts, seams, and splits vary in effectiveness and cost. Manual sorting is the least-reliable method, but is most often used as a quick fix for either internal or external containment. The effectiveness of manual sorting depends greatly on the sorter’s training and diligence, and the quality of boundary samples provided. Under the best circumstances, manual sorting is only 70% effective. In other words, 30% of defective parts typically escape detection.

The use of totally automated inspection is by far the most effective and reliable route. However, no single inspection technique fits all circumstances. Inspection methods most appropriate for detecting seams and bursts include eddy current, vision, and ultrasonic resonant methods. Often, it takes a combination of these methods. Additionally, how parts are transported and located at checking stations determine the effectiveness of detection. In many cases, parts must be rotated for verification over the entire periphery of the parts.

Because there is already widely available inspection technology, the feasibility of automated inspection depends strictly upon the economic justification. The feasibility equation must include the capital cost of the appropriate inspection equipment, the selling price and volume of parts being inspected, and a clear understanding of customer expectations. The decision to include totally automated inspection must always be made in close cooperation between manufacturers and customers.

Seams that cause split heads and head bursts are unavoidable defects that occur when cold heading fasteners. (Cold heading, also called cold forming, is a fast and more efficient method for making standard and special fasteners and custom-shaped components.) There is a handful of known root causes that can cause split heads and head bursts. Many of these causes can be mitigated or prevented during manufacturing. Manufacturers and customers must often examine and negotiate the acceptability of these defects based on the limits defined in industry standards. In cases where, for one reason or another, the customer does not tolerate any degree of splits and bursts, detection methods—namely manual sorting and automatic inspection—are called for. In such cases the customer and manufacturer must reach a commercial agreement to cover the additional cost of total and complete inspection.

Salim Brahimi is director of engineering & technology, Industrial Fasteners Institute, Cleveland.

About the Author

Salim Brahimi

director of engineering & technology

Salim Brahimi is director of engineering & technology, Industrial Fasteners Institute, Cleveland.