Schweiger Formenbau (Schweiger Mold Making) relies on automation to produce high-precision injectionmolds at competitive costs in Germany. In order to achieve the required, high process reliability, the large-scale mold manufacturer does not make any compromises. For tooling they rely on tool holders, shrinking, balancing and tool presetting technology from the system supplier HAIMER.

The owner-managed Schweiger GmbH & Co. KG from Uffing at Staffelsee in Bavaria specializes in one of the most demanding industries: the automotive industry. For Managing Director Anton Schweiger and his approximately 75 employees, this means having to meet the highest standards of precision and quality with every injection mold produced. Additionally, they are competing in a global market, which, among other things, is subject to enormous cost pressure.

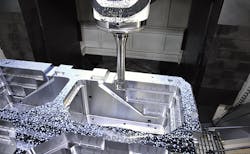

However, facing the strain of global competition, the qualified toolmaker and his team have adjusted and positioned themselves accordingly. They rely on an automated process chain which ensures absolute security and ends with injection molds that meet all requirements. In 2016, for example, the company built a new production hall and invested in two DMC 210U and 270U 5-axis DMG Mori machining centers, which are capable of processing even XXL components in one clamping operation. Equipped with an appropriate pallet automation, the machines run around the clock seven days a week - and all with just one-person shifts. On the weekends they run completely unmanned. This requires highest process reliability across all relevant components and functions.

In this respect, Anton Schweiger has also focused on tool clamping technology, the often overlooked interface between spindle and tool. It bears great responsibility for the quality of the machining, the service life of the spindle and the tool life.

Teamwork for the best solution: Schweiger production manager Andreas Orterer (right) with Oliver Lechner (center), HAIMER sales manager for Southern Germany, and machine operator Rafal Stawski (left).

The milling specialists at Schweiger swear in this respect by the support and counsel of HAIMER GmbH, Igenhausen. In 40 years, the family-owned company has become the market leader for tool clamping technology in Europe and is considered to be the world leader in tool shrinking and balancing technology.

Quality makes the difference

For Andreas Orterer, production manager at Schweiger, the main argument for this strong partnership is the quality delivered by HAIMER, "With Haimer products, we can be sure we will always receive the quality that meets our high standards."

Schweiger currently uses in the thousands of HAIMER tool holders with shrink fit technology. In addition, there are two Power Clamp shrinking devices and a Tool Dynamic balancing device in the production.

Schweiger Tool and Mold Making specializes in the machining of large workpieces and deep cavities. The milling specialists use HAIMER shrink fit chucks for their machining, in some cases coming from the supplier’s large standard product range and in others special custom-made solutions.

Andreas Orterer adds, "From Haimer, we get all tooling from a single source, which suits us very well. In addition, you notice the shrinking and balancing devices have been developed by machinists. They are easy to use and lead to fast results. "

This is also true for the Microset presetter UNO autofocus 20 | 70, which has its place between the shrinking and the balancing devices at Schweiger.

This machine has become a "HAIMER" product since the Bavarian company took over Microset Tool Presetting Technology in Bielefeld at the beginning of 2017. Compared to the manual version, the UNO autofocus is able to automatically focus the cutting edge for measurement of the C-axis. Especially when it comes to tools with several cutting edges on the circumference, this option proves to be enormously time-saving. All in all, the device allows set-up time reductions of up to 70 percent just from presetting outside of the machine.

Andreas Haimer, Managing Director of Haimer GmbH, explains, "With the acquisition of Microset Tool Presetting Technology we have become a system supplier for tool management. Microset perfectly complements our existing portfolio of high-precision tooling, clamping, shrinking and balancing technology, in such a way as to enable us to provide even greater support to our customers. "

Automatically highest runout accuracy

The level of satisfaction Anton Schweiger, Vice President of the Association of German Tool and Mold Makers (VDWF), has in his partnership with HAIMER and his tool holders can be measured by the fact that he has been using them for more than two decades.

When the toolmaker bought the first HSC machine about 20 years ago, he switched from mechanical collet chucks to HAIMER shrink fit chucks because of the improved runout accuracy. Compared to the products of other suppliers, the HAIMER shrink fit chucks won him over with its superior quality, "a company goal that HAIMER and ourselves have in common.” “If you take the example of the shrink fit chucks, this can be seen in the runout accuracy, which is, by default, below 3 μm."

This is an important prerequisite for the tool makers from Uffing. After all, they do not produce injection molds for cheap consumables, they create highly sophisticated molds used in premium vehicles - for example used to make headlight end plates in 2-component injection molding. These customers place high demands on the end products and do not accept the slightest blemish. Accordingly, the injection molds have to meet similar requirements: as a rule, surfaces should be smooth as glass and tolerances of less than 2/100 mm must be maintained.

Slim, smooth running and in a wide range of special designs: a four-digit number of HAIMER shrink-fit tool holders ensures stable processes and high precision at Schweiger.

One of Schweiger's main areas of focus in production is the milling of large complex molds, whereby individual workpieces can weigh up to nine tons. The cavities are often very deep. Typically between 300 to 400 mm, sometimes even up to 500 or 600 mm deep. This requires slim shrink fit tool holders, the use of shrink fit extensions as well as tools with extremely long shanks. "Another strength of Haimer. The company offers a large variety of tool holders standard. If required, however, we can always order a wide range of special designs," emphasizes production manager Orterer. He points again to the extremely good runout accuracy properties, which apply equally to standard and special tool holder designs. Not only do they contribute to excellent machining results, they also spare the spindle and the tools.

A long tool life enables unmanned operation

In general, a longer spindle life means considerable costs savings, but the tool live is even more important in automated production. "In order to work unmanned, I need an absolutely reliable, long-lasting system of spindle, tool holder and tool," explains Anton Schweiger.

Schweiger machines many large injection molds automatically in one clamping operation – for 40 to 50, sometimes even 100 hours, non-stop. A broken tool or even a spindle damage during unmanned operation would be fatal. In addition, a rigid and stable connection is important to achieve the requested surface quality. "A key to this is the Haimer tool holders," adds the company owner, "they enable process-reliable machining."

All from a single source: Schweiger Tool and Mold Making uses tool holders, shrinking, balancing and presetting technology from HAIMER.

Not every requirement of the toolmaker can be optimally fulfilled with standard tool holders. Anton Schweiger especially appreciates the close cooperation with the HAIMER specialists and the flexibility of the company in Igenhausen. "For us it is important that Haimer listens to the users," emphasizes the entrepreneur. His HAIMER contact, Oliver Lechner, sales manager for Southern Germany, always responds quickly to inquiries. Lechner comments, "After that, we supply Schweiger with the required custom-made products, such as special, conically shaped face mill arbors that allow the machining of cavities up to 360 mm depth." Anton Schweiger adds, "These tool holders are perfectly adapted to the tool diameter and the respective cavities. That is how I can, without any concerns, let the machines work without supervision - even for roughing."

Specialist for complex large-scale molds

The tool and mold making company, Schweiger, was founded in 1962 by Erich Schweiger. Today, under the management of his son Anton Schweiger, it has around 75 employees and generates around 10 million Euros in sales each year. Their core business consists of complex injection molds weighing between 5 and 30 tons, 99 percent of which are supplied to the automotive industry. They are mainly used for the production of headlight covers, optical and visual components. Customers include German premium manufacturers, as well as their 1st tiers. In addition to automated production with standardized processes, Schweiger sees its strength in turn-key solutions. The services range from support in product development to series production and aftersales services.

About the Author

Haimer USA

HAIMER is a family run, medium size company headquartered in Igenhausen, Bavaria near Augsburg, Germany. It designs, produces and sells innovative, high precision products for metal cutting as well as for other branches including automotive, aerospace, energy, rail and general machining.

Haimer's product offerings include tool holders in all popular interfaces and lengths, solid carbide tooling and grinding wheel adapters.