Selecting Your Digital Distribution Center’s Waving Strategies

In the new digital age, distribution centers are dealing with increasingly diverse order profiles. Wholesale orders are changing from pallet size orders to case size orders. Digital orders from the web are becoming more frequent with a smaller number of items as consumers only order what they need.

In previous articles we examined the need to review picking processes and picking technologies. This article highlights the possible waving strategies that will enable new digital order processes. Waving allows distribution center management to use order characteristics that can help plan out labor costs, expected productivity goals, and workloads across equipment. Digital orders are often time sensitive, making wave planning important in managing the order and work flow of the facility to have orders shipped on-time.

Waving Planning

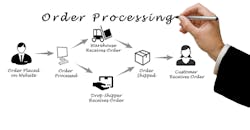

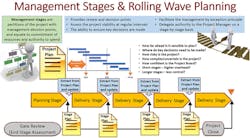

Wave planning is a term for the process used in a warehouse management system (WMS) to organize the daily work flow based on order characteristics, labor and equipment constraints. Wave planning involves applying short-interval schedules (waves) that balance order characteristics and constraints to ensure orders and workloads flow effectively through the distribution center. An important factor in wave planning is enabling order departure plans with the available labor. When the plan is satisfactory, it is accepted. Wave planners then release the waves to the warehouse sequentially throughout the day, allowing managers to coordinate parallel and sequential activities required to complete the daily work.

The main goal of wave planning digital orders is to ensure the orders are processed efficiently while they meet their departure plans and ship to the customer on-time. Cut-off times are used in coordination with digital order departure plans to ensure the wave of digital orders can be picked, packed and shipped on-time.

Digital vs. Wholesale Waves

In a distribution center where wholesale orders are being processed with digital orders, wave planning can be the distinguishing factor. Web promotions may spike demand for a few items, and these items can be batched in a wave to ensure picking efficiency. Because labor and equipment constraint can seriously affect the processing times of waves, the design of the facility should ensure flexibility of these constraints can be managed by wave planning. For example, when sorting equipment is used to match batch picking with the outbound containers of an order, it should be designed so a given number of shuts are assigned to digital orders that can be partitioned. This allows two waves to be processed at the same time over the entire sorter. If this partitioning cannot happen, it may be better to send the digital orders to a put wall so digital orders are not left waiting on the sorter.

Releasing Waves

The balancing act of managing wholesale and digital orders in the same facility comes down to how work is released to the floor. Wholesale waves can be large and demand a great deal of facility resources, meaning digital waves may be shut down while waiting for the wholesale wave to complete. But if the facility is designed with some flexibility and extra capacity, resources can be assigned to completing digital orders, allowing digital waves to be completed in parallel along with larger wholesale waves. For example, digital waves can be picked using discrete order or cluster picking concurrently as the wholesale waves are being picked. Batch picking can happen in parallel waves as long as the equipment can be partitioned or another order consolidation technique can be used.

Closing WavesAt the end of the wave planning process, it is important to know when to properly close released waves. If the fulfillment of a wave is delayed, it can cause lingering problems with replenishment, backed-up order consolidation and equipment failure. Equipment being used for parallel waves may get caught up with the delayed wave, causing other waves on that equipment to be subsequently delayed. Closing the problem wave frees up those resources so the parallel waves may continue uninterrupted. For digital orders, using continuous waving or waveless execution systems, or partitioning shared equipment with wholesale waves, can keep digital orders flowing through the facility to shipping.

Waves vs. Lean Time Order Release

Lean manufacturing has taught us principals such as “lot size of one” and “excess capacity” are preferred. These principals were examined closely by the manufacturing financial community and proven to be more important to meeting customer needs versus other sub-optimal financial goals. The same is true for time sensitive orders in the distribution center, providing extra capacity so customer delivery dates can be met. Large waves may work for wholesale orders and two or three day lead time digital orders. But for time sensitive digital orders where the customer is willing to pay for premium expedited freight, the orders need to be processed with greater urgency. Such urgency may require digital orders be released as they are received, especially when the order is received within a certain time window close to the carrier pick-up time. This emerging execution technology is referred to as “continuous waving” or “waveless.” The warehouse execution systems (control systems) are handling the release of work to the distribution center to help flatten the peak and valleys of work produced by classic WMS waving.

Conclusion

Digital distribution relies as much on picking methods, equipment and waving to ensure proper fulfillment of orders. Digital distribution can co-exist with the wholesale business in the same distribution center, so inventory, labor and equipment can be properly utilized. Continuous waving/waveless execution systems will be used more as the digital landscape of fulfillment evolves. To properly plan your digital distribution environment, a skilled professional is worth their fees multiple times over, as they design the digital distribution center so orders will be properly fulfilled while efficiency and utilization of the facility are being optimized.

For more info on honing your digital order profile, visit www.wipro.com.