Kobe Aluminum Automotive Products in Bowling Green, KY, will start its seventh expansion project later this year, a $53-million program to increase output of forged aluminum automotive suspension components to more than 11.6 million parts annually.

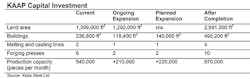

The new project will begin this summer, once a similar, ongoing expansion is completed. That current expansion was announced in late 2015 and will result in KAAP operating three aluminum melting and billet casting line, plus eight closed-die forging presses. Full production will be underway this summer, increasing the annual output from 6.48 million pieces per year (540,000 per month) to 9 million per year (750,000 per month.)

The project to begin later this year will result in an operation with four melting and casting lines and 10 forging presses. Production will begin in Q3 2018.

KAAP is a joint venture by Kobe Steel, Mitsui & Co. Ltd., and Toyota Tsusho Corporation to produce aluminum forged suspension products in the United States. The same partnership has similar ventures forging aluminum automotive suspension parts in Japan and China.

Last year, Kobe Steel announced plans to Kobe Steel Ltd. plans to establish a new company in Bowling Green, to manufacture aluminum extrusions for automotive bumpers and auto frames. The $46.7-million Kobelco Aluminum Products & Extrusions Inc. venture is due to start production later this year.

The steady expansion of KAAP is indicative of automakers’ growing reliance on lightweight components to reduce vehicle weight for passenger cars. Initially, KAAP’s suspension parts were supplied mainly to Japanese transplant automakers, though now it supplies domestic OEMs, too. And, in its expansion program it is indicating that it anticipates forged aluminum suspension products will be adopted for other automotive market segments, too.

Kobe noted the U.S. automotive market is forecast to continue expanding, from roughly 17.5 million passenger cars produced in 2016 to a 19 million in 2020.

About the Author

Robert Brooks

Editor/Content Director - Endeavor Business Media

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries. His work has covered a wide range of topics including process technology, resource development, material selection, product design, workforce development, and industrial market strategies, among others.

Currently, he specializes in subjects related to metal component and product design, development, and manufacturing—including castings, forgings, machined parts, and fabrications.

Brooks is a graduate of Kenyon College (B.A. English, Political Science) and Emory University (M.A. English.)