Ellwood Texas to Forge Titanium Parts for GE Aviation

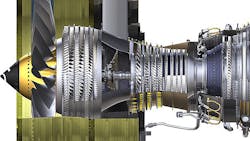

Ellwood Texas Forge Houston, a closed-die forging operation, has drawn a new three-year contract that expands its supply of parts for GE Aviation’s production of the CFM International LEAP series jet engines. The LEAP commercial aircraft engines were developed by CFM (a joint venture of GE Aviation and Snecma, a Safran subsidiary) to power jets produced by Airbus, Boeing, and Commercial Aircraft Corp. of China Ltd. (Comac.)

The value of the new contract was not announced.

GE Aviation assembles the engines at its own operations in Durham, NC, and Lafayette, IN.

Ellwood Texas Forge Houston is one of two, Texas closed-die forging plants operated by the Ellwood Group Inc. The Ellwood Closed Die Group operates multiple hydraulic presses, screw presses, steam hammers, and a computer-controlled, 80-meter-ton counter-blow hammer, forging near-net-shape forgings in carbon, alloy, and stainless steels, plus nickel and titanium alloys.

The Closed Die Group’s primary markets include, aerospace, construction, defense, general industrial, marine, mining, oil-and-gas, and power generation markets.

Ellwood Forge Texas Houston continues to work on an earlier contract producing nickel-based alloy forgings for the GE Aviation program. Deliveries of the new parts will begin during Q3, continuing through December 2020, concurrent with the initial parts won.

The forger did not identify the new forgings to be produced, except to describe them as “rotating” parts. In addition to closed-die forging, these parts will be heat-treated, machined, and inspected with CMM and destructive and non-destructive testing procedures.

“GE’s willingness to place additional LEAP business with ETFH is a testament to GE’s confidence in ETFH, and our excellent, long standing relationship,” according to Richard Allender, president of the Ellwood Closed Die Group. “The hard work, focus, and performance of our team, from business development through engineering and operations, have made wins like this possible.

“We are extremely pleased to expand and continue our partnership on GE’s most critical engine platform,” Allender added.

About the Author

Robert Brooks

Editor/Content Director - Endeavor Business Media

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries. His work has covered a wide range of topics including process technology, resource development, material selection, product design, workforce development, and industrial market strategies, among others.

Currently, he specializes in subjects related to metal component and product design, development, and manufacturing—including castings, forgings, machined parts, and fabrications.

Brooks is a graduate of Kenyon College (B.A. English, Political Science) and Emory University (M.A. English.)