Firth Rixson Starting $200-Million Jet Engine Contract

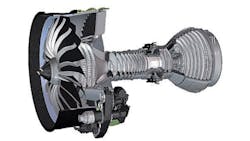

Forging group Firth Rixson Ltd. has secured a long-term supply contract estimated more than $200 million with Snecma, a French manufacturer of military and civil aircraft engines and part of the high-technology Safran Group, for closed-die forgings and seamless rings as part of its LEAP engine manufacturing program.

The LEAP high-bypass turbofan jet engines for commercial aircraft were developed by CFM International, which is a joint-venture of Snecma and GE Aviation. The engines are produced by both partners in their own plants, and then supplied to various aircraft OEMs for numerous jet programs. CFM has indicated a long-backlog of orders for the LEAP engines, stretching production plans out for several years. Among the aircraft that are powered by LEAP engines are the forthcoming Airbus A320neo and Boeing 737 MAX series, as well as the Comac C919.

Firth Rixson consists of three operating divisions, producing rolled rings, closed-die forgings, and specialty metals. Aerospace applications dominate its list of products, but it also supplies manufacturers of equipment and systems for power generation, oil and gas, defense, transportation, and other markets.

Late last month, Firth Rixson agreed to a $2.85-billion takeover offer from Alcoa Inc., which is aggressively expanding its foundation in the aerospace market with new capital programs and long-term supply contracts.

Firth Rixson stated the new supply deal concerns rotating components for the LEAP-1A, LEAP-1B and LEAP-1C engine programs, to begin this year and extend to 2023.

"Firth Rixson have great admiration for the technology that Snecma produces, from the best-selling CFM56 engine, now to the LEAP engine family and with such advanced technology comes the requirement for a first-class supplier," stated David Mortimer, CEO. “This contract demonstrates the robustness of our critical rotating engine discs and rings supply, as well as reiterates our continuous improvement focus in-line with market demand and adaptation

Mortimer noted that manufacturing of the parts would involve Firth Rixson plants in the U.S., U.K., and China, adding that fact demonstrates the group’s availability to support global sourcing initiatives.

About the Author

Robert Brooks

Editor/Content Director - Endeavor Business Media

Robert Brooks has been a business-to-business reporter, writer, editor, and columnist for more than 20 years, specializing in the primary metal and basic manufacturing industries. His work has covered a wide range of topics including process technology, resource development, material selection, product design, workforce development, and industrial market strategies, among others.

Currently, he specializes in subjects related to metal component and product design, development, and manufacturing—including castings, forgings, machined parts, and fabrications.

Brooks is a graduate of Kenyon College (B.A. English, Political Science) and Emory University (M.A. English.)