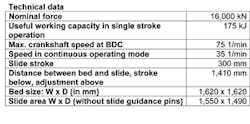

SCHULER GROUP introduced a 16,000-kN-strong drop forging press with ServoDirect Technology, built for an automotive industry customer and introducing freely programmable slide motion to the forging industry. Shorter pressure dwell times and an increased output of 35 strokes per minute, all in continuous operation are just some of the benefits.

“The pressure dwell time can be reduced to a minimum while also optimizing the time for spraying and transporting,” explained Jochen Früh, managing director of Schuler Pressen and Head of the Technology Field Forging. “That means that output in high-speed mode can be increased to 40 pieces per minute, while die service life can be prolonged by 15 to 20 percent due to reduced heat input.”Instead of a drive running continuously at the same speed, servo forging presses feature one or more torque motors which are either flanged to the driveshaft directly or via a planetary gearbox. The PK 1600 SDT model that Schuler unveiled in Erfurt boasts two Oswald torque motors, each with a rated capacity of 377 kilowatts: highly dynamic drives which act directly on the crankshaft. Due to the elimination of the flywheel, clutch, brake and drivebelt, the amount of mechanical and electrical loss has also been reduced. “This makes overall energy consumption more favorable and reduces the amount of maintenance and servicing required,” states Jochen Früh.

The intermediate storing of energy in an external flywheel storage device not only reduces consumption but also the load on the factory network caused by energy peaks. The electrical energy created by the regenerative braking of the drive motors is transformed into mechanical rotation energy. This is then returned to the servo drives as electrical energy during the brief peak energy needs of the drive motors – such as during heavy acceleration of the slide’s downward motion and the forming process.

For this reason, among others, ServoDirect Technology is well suited to tryout operation: the variable slide speeds enable slow and sensitive running of the press and transfer system. This means that dies can be put into operation more swiftly and securely.

Visit www.schulergroup.com