The power of electricity is nothing to treat lightly. If the clamp meter you use is underrated for the task you’re performing, it can damage equipment, cause an arc flash, explode or deliver a deadly shock to you (and possibly others nearby). How do you know if you have the right meter for the job?

An Appropriate CAT Rating is Real Protection

A clamp meter combines the capabilities of a multimeter with a current sensor. A well-built meter offers vital protection against electrocution and arc explosion. It will carry a Category (CAT) rating together with certification by an independent test laboratory. Without a proper rating and certification, you have no way to tell if a clamp meter has the necessary protection against electrical transients that could lead to insulation breakdown or arc flash.

The International Electrotechnical Commission (IEC) 61010 specifies CAT and voltage ratings for electrical environments. These categories provide guidance to help protect you from the increased risks of making live measurements when testing or troubleshooting a power system. With CAT environments II, III, and IV, the available fault current in these high-energy circuits can reach as much as 100 kVA.

The CAT Rating You Need Depends on Where You’re Working

A high CAT number refers to an electrical power system with higher available power and higher energy transients; the higher the short-circuit fault current available, the higher the category.

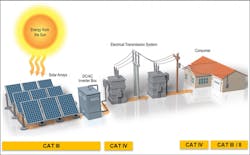

- CAT IV: This environment is the “origin of installation,” where the connection is made to utility power or measurements on devices installed before the main fuse or circuit breaker in the building installation. Examples include electricity meters, primary overcurrent protection equipment, outside and service entrances, the service drop from pole to building, the run between the meter and the panel, and overhead lines to detached buildings or underground lines to a well pump.

- CAT III: This category covers 3-phase distribution, including single-phase commercial lighting. CAT III includes measurements on distribution boards, circuit breakers, and wiring (including cables, bus bars, junction boxes, switches, and socket outlets) in the fixed installation. Equipment in fixed installations (such as solar facilities) may include switchgear and polyphase motors, bus and feeders in industrial plants, feeders and short branch circuits, distribution panel devices, lighting systems in larger buildings, and appliance outlets with short connections to the service entrance.

- CAT II: The CAT II environment consists of single-phase receptacle-connected loads, including the main circuits of household appliances, portable tools, and similar loads. These are outlets and long-branch circuits more than 30 ft (10 m) from a CAT III source, as well as outlets more than 60 ft (20 m) from a CAT IV source.

CAT ratings are key to understanding how to choose and use a meter or any other test instrument. A test instrument designed to the CAT III standard can resist much higher energy transients than one designed to CAT II standards. Using a meter that’s underrated for the environment you’re working in can be dangerous for you and the equipment, too.

Consider the Meter’s IP Rating for Working in Harsh Conditions

Along with CAT ratings, you’ll want to consider whether you’re working in volatile or harsh conditions when selecting the right meter for your job. Ingress protection (IP) codes are classifications associated with IEC 60529, the standard that defines how instruments’ mechanical casings and electrical enclosures must protect the inner mechanism against intrusion, dust, accidental contact, and water.

The IP code consists of two digits that indicate the tool’s resistance to dust and water. The first number relates to keeping out solid particles, and the second number refers to how deeply it can be submerged in water and continue to function.

| First Digit | Solid Size | Protects Against |

| 0 | — | No protection |

| 1 | >50 mm (2 in.) | Any large surface of the body |

| 2 | >12.5 mm (0.5 in.) | Fingers or similar objects |

| 3 | >2.5 mm (0.1 in.) | Tools or thick wires |

| 4 |

>1 mm (0.04 in.) | Granular objects, such as most wires, screws, etc. |

| 5 |

Dust protected | Not entirely prevented but must not interfere with satisfactory operation |

| 6 | Dust tight | No ingress of dust — dustproof |

| Second Digit |

Water Condition | Protects Against |

| 0 |

— | Not protected |

| 1 |

Dripping water | Vertically falling water, no harmful effect |

| 2 | Dripping water, 15-deg. tilt | Vertically falling water, unit tilted up 15-deg. from its normal position |

| 3 | Spraying water | Water falling as a spray at up to 60° |

| 4 | Splashing water | Water splashing from any direction |

| 5 | Water jets | Water projected by a nozzle from any direction |

| 6 | Powerful water jets | Water is projected in powerful jets by a nozzle from any direction |

| 7 | Immersed <3 ft (1 m) | Waterproof to 1 meter for 30 minutes |

| 8 | Immersed >3 ft (1 m) | Continuous immersion |

Independent Certification Verifies Safety Standards

Improperly used or unrated test equipment can sometimes explode. It’s critical to your safety that your meter (and other electrical testing tools) have been independently evaluated to survive voltage transients and certified to meet safety standards. Organizations like the IEC and the National Fire Protection Association (NFPA) aren’t responsible for enforcing their test tool safety standards. When you’re choosing any test instrument, make sure you see a label that indicates it’s been certified by at least one independent testing agency.

On any job, wherever it is, your safety depends on your tools. Choosing the right meter means matching the tool’s capabilities, ratings, and certifications with the environment you’re in and the work you’re doing.

Michael Crepps, Fluke Application Specialist, joined Fluke in 2016 as a Technical Support Engineer. Michael has been providing support and training on electrical test and measurement tools for the past 7 years. Prior to Fluke, Michael worked in the bio-tech industry providing technical expertise in manufacturing and development. Find out more about Fluke tools at Fluke.com

About the Author

Michael Crepps

Product Application Specialist, Fluke Corporation

Michael Crepps, Fluke Application Specialist, joined Fluke in 2016 as a Technical Support Engineer. Michael has been providing support and training on electrical test and measurement tools for the past 7 years.

Prior to Fluke, Michael worked in the bio-tech industry providing technical expertise in manufacturing and development. Find out more about Fluke tools at Fluke.com