Choosing a Sharpening Stone

BENCHSTONES

Benchstones are the most commonly used sharpening stones and are also known as oilstones or whetstones. As the term oilstone suggests, a thin layer of oil is typically used as a lubricant on this type of stone to enhance sharpening performance and to keep the sharpening surface from loading or glazing.

Man-made benchstones come in a variety of sizes and shapes and are available in a range of grit sizes: coarse (80 to 100 grit), medium (150 to 220 grit), and fine (280 to 320 grit). Benchstones are durable, wear slowly, and retain their flatness significantly longer than waterstones.

Man-made benchstones are primarily available in two different types of abrasive: aluminum oxide (India stones) and silicon carbide (Crystolon stones).

India Stones

- India aluminum oxide stones are favored for imparting durable, smooth-cutting edges. The abrasive grain is very friable, so the edges continue to retain sharp cutting edges with use. In addition, this friability means that India stones remove slightly less metal during the sharpening process, extending the life of your knives and tools.

Crystolon Stones

- The silicon carbide grade used in Crystolon stones is more durable than aluminum oxide, making the Crystolon silicon carbide stones more aggressive. In removing more metal with each sharpening pass, you can speed up the sharpening process, which is preferred when the speed of sharpening is more important than the fineness of the cutting edge.

Because sharpening is frequently a progression, first repairing an edge with a coarse grit stone and then perfecting the edge with a fine-grit stone, many people choose to buy a combination stone, which utilizes a coarse grit on one side and a fine grit on the other side. It is also common practice to use a Crystolon stone for initial coarse-grit sharpening before moving on to an India stone and then finishing with an Arkansas stone, a natural benchstone.

Arkansas Stones

Natural stones have been used for hundreds of years. The most popular natural stones available today are made from Ozark novaculite (silicone quartz), which is quarried in Arkansas and cut to shape to make what is commonly known as Arkansas stones. These sharpening stones are very hard and dense and will not cut as fast or as aggressively as man-made or diamond stones. Due to their unique composition, Arkansas stones polish as they sharpen, imparting an extremely fine, smooth edge. Because of this, they are typically used as the final sharpening step after an India or Crystolon stone is used or to maintain an already sharpened edge.

All Arkansas stones are not alike due to the porosity and density of the mined material. Soft Arkansas (extra fine) stones are the coarsest-grained and least dense of the natural stones. They are used primarily to sharpen and hone tool and knife edges to an even, polished surface, frequently after sharpening with man-made stones. Hard translucent Arkansas (ultra-fine) stones are the finest-grained and densest natural stone available and are used to produce the keenest, most precise finish possible, as well as polished, razor-like edges.

Comparable to hard Arkansas stones, the man-made Ascent ceramic benchstones are the newest to market.

Ascent Ceramic Stones

-

These extremely hard, wear-resistant Ascent stones are excellent for producing the finest edge on an already sharp blade. With an ultra-fine surface finish, these stones are comparable to hard Arkansas (fine grit Ascent) and 1500 grit waterstones (ultra-fine Ascent). These stones shouldn’t be used with a lubricant, and therefore, the stone surface needs to be cleaned after each use for optimal performance.

WATERSTONES

Waterstones are synthetic stones that have become increasingly popular. They are designed to be much softer and more porous than traditional benchstones, with abrasive grit from the stone forming a fast-cutting slurry on the surface of the stone during the sharpening process.

Waterstones should be completely soaked in water for several minutes prior to use, ensuring that the water has penetrated through the entire stone. Waterstones are typically made from aluminum oxide or silicon carbide, depending on the grit size, but the abrasive/bond combination makes these stones cut faster than benchstones and impart a much smoother finish.

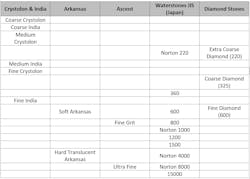

Waterstones are available in a range of grit sizes, like man-made benchstones, but are usually available in much finer grits than benchstones. Waterstone grits are typically measured based on the Japanese system and are not directly comparable to grit sizes used for benchstones and diamond stones. For example, a 1000 grit water stone is close in surface finish to a 320 grit benchstone. Additional comparisons can be found in the table below.

Because Waterstones are softer than benchstones, they wear much more quickly and need to be flattened frequently for optimal performance.

DIAMOND STONES

Diamond stones are the fastest and most aggressive sharpening stones. They are produced by bonding microscopic diamond crystals to flat perforated or solid steel plates. Diamond stones are long-lasting, fast sharpening, and will retain their flatness longer than water stones and benchstones. They can be used dry or with water or oil as a lubricant.

Because the diamonds are hard and aggressive, diamond stones remove slightly more material than similar grit benchstones and water stones. In addition, they generally impart a less polished surface than other sharpening stones. Some sharpeners choose to use hard Arkansas, Ascent ceramic stones, or fine grit water stones as a polishing step after sharpening with diamond stones.

What Size Sharpening Stone Should I Buy?

Once you choose the type of sharpening stone you want to use, how do you determine which size to select? In general, sharpening is more effective when you match the size of your stone to the size of the blade you are sharpening. Small pocket knives can be sharpened on 3-inch stones and large kitchen knives are best sharpened on 11-1/2-inch stones.

For the best results, choose a size that allows you to sweep the entire length of the blade across the stone in every sharpening motion.

Which Sharpening Stone is Right for You?

There are many different sharpening stones, but once you’re familiar with the most common types, you’ll be able to choose the right stone for your project.

For a quick overview and comparison of the finishes produced by the benchstones, water stones, and diamond stones discussed in this article, see a summary below.

- Benchstones wear slowly and retain their flatness longer than Water stones. They are available in a number of formulations and grit sizes, allowing you to achieve a wide range of desired finishes depending on the type you choose.

- India Stone: imparts durable, smooth-cutting edges

- Crystolon Stone: produces a less fine cutting edge but sharpens quickly

- Arkansas Stone: polishes as it sharpens for a fine, smooth edge

- Ascent Stone: ultra-fine finish on an already sharp blade

- Waterstones wear more quickly and require frequent flattening, but they produce a smoother finish than benchstones.

- Diamond stones retain their flatness longer. They are the most aggressive and remove more material when sharpening, resulting in a less polished finish.

To find the right sharpening stone for you, browse Norton's selection of sharpening stones here.

Trish Dawson is a Product Manager at Norton | Saint-Gobain Abrasives.