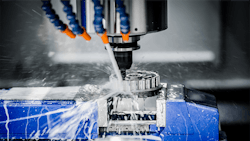

CNC vs. 3D Printing: What's the Best Way to Make Your Part?

A recent trend in manufacturing enabled by stronger materials is a desire to 3D print functional parts that are currently CNC machined, whether that is done in-house or outsourced to a third-party vendor. The cost and time reduction case for 3D printing is compelling, and when you bring a part into the cloud-based Eiger software to see that you could have parts next day for a fraction of the cost you pay today, it seems like a no-brainer.

The purpose of this article is to help you consider the full scope of 3D printing and CNC machining and choose the best option for your needs.

Physical Considerations

Geometry

Feature size

Both processes are constrained by tool size; in the case of CNC, the tool diameter dictates the smallest negative feature that can be created. In the case of 3D printing, however, the nozzle diameter dictates the smallest positive feature that can be produced. The nozzle diameter for extrusion-based 3D printers is typically between 0.25mm and 0.8mm, and the minimum feature size for those machines is 4 times that, resulting in a minimum feature size between 1.0mm and 3.2mm.

For more detail on minimum feature size for continuous fiber reinforcement, check out this post from the Markforged blog, and the Composites Design Guide.

Surface finish

With the right tools, CNC machines are capable of producing much smoother surfaces than 3D printers. 3D printers are capable of producing parts for fit and finish, but for parts that require exceptional smoothness for mating with other precision components, CNC machining may be preferable.

Tolerances

Some of the best composite 3D printers can hold dimensional tolerances down to +/- 0.005”, and typically have a compliant surface for press-fitting. Tight tolerance features on 3D-printed parts can be post-machined. However, depending on the other features on the part, it may be easier to machine the whole thing. Your results may vary based on machine, material, and part geometry.

Loading

Non-structural parts are typically easy targets for conventional 3D printing. Structural parts that need to withstand significant physical loads can be produced with continuous fiber reinforcement, or by CNC machining. While continuous fiber reinforcement can provide significant strength improvement over other 3D printed parts, composite parts are stronger in two axes (X, Y) than in Z, and do not exhibit isotropic properties like metal parts. To learn more about how this might affect designs and orientation of parts for printing, check out this blog post.

Environment

Temperature

3D printing and CNC machining are both capable of producing parts in metals and polymers, so the choice will revolve around which process is more readily available for forming the material that you need.

The service temperature of a particular metal typically has some relation to its melting temperature. “Pure metals usually weaken seriously at about half the melting point on the absolute temperature scale (melting point in degrees F plus 459).” Alloys can typically push the useful range higher, in some cases to about 65% of melting temperature.

3D printed composites and polymers have service temperature limits lower than metals. Markforged materials typically should not be used for extended periods at elevated temperatures above 150°C.

Moisture

Some polymer filaments absorb moisture and may lose strength through prolonged exposure or submersion. A coating, such as Liquitex, may be required. Moisture typically does not affect aluminum but may cause steel to rust.

Chemicals

If your part will be subjected to any chemicals, check the chemical compatibility of your material with the chemical. While many metals are suitable for use with a variety of chemicals, always check for compatibility before introducing a new material or environment. Markforged nylon-based materials are chemically resistant and are unaffected by most petrochemicals. They are not suitable for use in strong acid or base environments.

Economic Considerations

When Do You Need It?

Machining in-house

If the part is needed immediately, there are no other holdups to the operation, and you have a machine, operator, materials, and work holding available, you should CNC machine your part. If there are more urgent jobs, or the part can wait, 3D printing can usually get you a part in hand the next day, freeing up operator time for more critical tasks.

CNC machining usually is capable of removing material much faster than 3D printing can deposit it. Size usually does not play into the time constraint as much for machining; the amount of material removal required is much more critical. If the part volume/stock volume ratio is very low (material removal is high), 3D printing may be a good option.

With 3D printing, the part size does affect time; larger parts take longer to print. if a part fits in the palm of your hand, you can usually have it the same day. With smaller parts, it can often be faster to 3D print than to machine. With a CNC machine, you must spend time getting stock, writing G-code, figuring out work holding, setting up tools, and cleaning up afterward. Some parts can print in the time it takes just to get a CNC machine ready.

Machining out-of-house

The process of outsourcing machined components to CNC machining services typically requires several days at minimum, between part review, creating drawings, sending out for a quote, and reviewing with purchasing. This, plus shipping and lead time from the shop, can sometimes result in a very lengthy process. Printing, in this case, may be a suitable way to check fit and finish or have a part ready the next day while a permanent part is being cut.

How Many Do You Need?

When you break down the cost of low-volume machined parts, the bulk of the cost comes from the time required for programming and setup; the actual time for cutting metal is generally fairly short. Scaling up production volume is generally achieved by making larger setups to cut more parts unattended. As part complexity and the number of features increases, programming time and the number of required setups may also increase. However, the cost of additional units drops off fairly quickly. Depending on the geometry, CNC per unit cost scales well into orders of hundreds or low thousands of units per month since the programming and setup can be reused.

With 3D printing, the programming (slicing) happens in a matter of minutes, and complexity has little effect on the programming time. While the first unit cost and effort is low, the per-unit cost is not affected much by volume. Scaling up production volume is generally achieved by bringing more machines online.

What is Your Budget for Equipment and Operators?

CNC machines can run unattended when properly set up, but typically trained full-time operators and programmers are critical to success. Machines are not always easy for owners to service, requiring expensive maintenance plans.

3D printers can easily run fully unattended, operators require minimal training, and programming is made easy by software. Machines are typically easy to service and have far less expensive maintenance costs.

CNC machines and 3D printers come in a range of prices based on features and build quality, but typically 3D printers can be owned for a significantly lower investment than a CNC machine.

The upfront and operating costs of additive manufacturing are low, making it ideal for low-volume applications such as prototyping and tooling. However, when scaling to higher volumes, subtractive manufacturing, and forming are more cost-effective.

Where Should You Fall on the CNC vs 3D Printing Debate?

The case is seldom as simple as a one-to-one process replacement, and 3D printing is not going to solve all of your production problems overnight. Economic constraints limit the cost-effective part quantity for 3D printing to low volumes, and the materials and process constraints may limit the application space. CNC machining, on the other hand, sees favorable economies of scale once quantities are a bit higher, usually on the order of hundreds of units per month.

This article was originally published on Markforged.

About the Author

Charles Lu

Application Engineer

Charles Lu (Mechanical Engineering, Georgia Tech '18) is an Application Engineer at Markforged and King of the North (eastern regions of North America). When he isn't helping customers uncover new ways to apply additive manufacturing to improve their businesses, you can usually find him hiking, biking, and/or searching for his next meal.