The Bureau of Labor Statistics estimates there are 10,805 lost-workday injuries due to falls from a ladder each year. Each of these injuries, on average, results in 18 lost workdays and a cost of $62,000. OSHA considers falls from ladders a significant risk and the need to address this workplace hazard was a driving factor in the basis for agency action that lead to their recent update of the Walking-Working Surface standard.

Ladders are also an identified source of overexertion injuries, which can lead to musculoskeletal disorders (MSDs). There were 12,700 reported MSDs due to ladder use between 2011 and 2016. On average, MSDs result in 12 lost workdays and a cost of $90,000. However, the most staggering statistic is that MSDs are 100% preventable (source: Center for Disease Control).

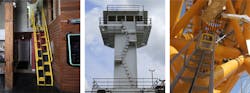

Alternating tread stairs are a safer choice for small spaces

The design of alternating tread stairs combines the space-saving benefits of a steep stair or ladder with a safer and more comfortable, user experience. The design incorporates more useable tread depth to stabilize the entire foot plus a central-stringer with a rubber bumper to lower the risk of hitting the nosing of a tread. Alternating tread stairs are used facing forward, just like standard stairs, to provide a more natural experience. Unlike ladders, which require three points of contact during use, users can safely transport items in their hands when climbing up and down alternating tread stairs.

3500+ combinations of standard options

Lapeyre Stair can manufacture an alternating tread stair for virtually any application. Each order is custom-built to an exact height up to 20 ft in a choice of either 56 or 68-deg. Standard options include a choice of three handrail options, a choice of material, and multiple finish/color options. Custom colors are also available. The standard fabrication lead time for alternating tread stairs is ten working days.

Lapeyre Stair also manufactures platforms, legs, bracing kits, and standard stairs. All their products are pre-engineered and designed for easy integration. The result is cost-effective, custom access solutions and quick turnaround times.

Customers with ongoing needs are eligible to receive the benefits of Lapeyre Stair’s preferred supplier program. Advantages of the program include volume-based discounts, priority quote turnaround times, field measurement assistance, on-site troubleshooting, and options for expedited fabrication lead times.

Take the next step toward increased safety

Visit www.lapeyrestair.com to view photos; get specs; download BIM and CAD models; request a quote; buy alternating tread stairs online; and more.

About the Author

Lapeyre Stair

More than 85,000 Lapeyre Stair alternating tread stairs are in use around the world today, allowing workers to easily and safely access crossovers, catwalks, and other tight spots that do not permit the use of conventional staircases.

At the company's headquarters outside of New Orleans, Louisiana, alternating tread stairs and traditional steel stairs are manufactured to meet specific height and building code requirements. A variety of options and additional products integrate to create complete, custom stair systems design for each, individual customer's specifications.

Alternating tread stairs can be ordered online and ship within 15 business days. Pre-engineered steel stairs are designed upon approval and ship directly to the project site, ready for installation.

As a dedicated stair manufacturer, Lapeyre Stair provides a complete outsource solution that allows customers to focus on higher priority aspects of their projects.