IMTS isn’t my first rodeo, but it is my second, and I don’t think anything could have prepared me for the sheer vastness that is this tradeshow. I knew what to expect to a degree, but I really didn’t expect to feel like a mouse in a hedge maze.

As you read before, 3D printing is all over this show; It’s all I saw anywhere I looked. It got to the point where I asked myself if this is all IMTS was: a giant 3D printing showcase. After getting a better lay of the land, I learned my assumption was not correct. This show has just about everything under the sun when it comes to manufacturing, but I wanted to point out a few booths that really grabbed my attention.

First up we have Velo3D – a new company on the market that specializes in 3D metal printing.

I know, I know, I just got done talking about how there were other things at IMTS, but I promise, they’re making a name for themselves.

Velo3D showcased their Sapphire System, which is a laser fusion metal additive manufacturing system. What sets them apart though, is that they have fine tuned the process to be able to manufacture complex geometries. Normally, other systems on the market require supports for geometry below 45-deg., but Sapphire goes down to 5-deg. without any support required. Yes, they basically 3D print in thin air.

Just look at this bottle opener they gave me. I can honestly say, this is the coolest bottle opener I’ve ever owned.

Also, Sapphire takes care of all the post-processing work of a 3D printed piece; There’s no finishing, coolant, grinding, whatever. So when it’s done, you’re done.

Moving on to the next booth that caught my eye, we have Hexagon Manufacturing Intelligence. Back in August, they released their Absolute Arm Range – we’re talking portable measuring arms here. Not only are the portable arms more accurate (within 6 microns) than the standard measuring machines, but they offer a modular wrist that is removable, so you can recalibrate right at the point of measurement. The arms come in seven sizes, from 1.2 to 4.5 meters, and the larger you get, the less accurate you get – but this allows them to offer measuring arms for every type of application.

This is just a cool Iron Man sculpture they used to demonstrate the measuring arm.

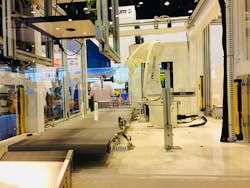

Last, but not least, is Omron. These guys have a broad range of specialties from robotics to safety components. It’s clear that Omron wants to make life easier for their customers, which is why they are now offering every component needed for a work cell. With recent acquisitions under their belt, they have a large breadth of technology to eliminate production time and rising costs.

The work cell you see above houses controllers, relays, sensors, a robot, and more – all from Omron. This way the user doesn’t have to cherry pick certain equipment from different companies and then try to mash them together and hope that it works out they way they want it to; it’s all there, ready to integrate with itself.

Stay tuned for more product information from IMTS in the weeks to come on the NED Directory. Omron also let me know about some exciting news coming up in December, so I’ll be sure to keep you informed when the time comes.

About the Author

Laura Davis

Editor-in-Chief, New Equipment Digest

Laura Davis is the editor in chief of New Equipment Digest (NED), a brand part of the Manufacturing Group at EndeavorB2B. NED covers all products, equipment, solutions, and technology related to the broad scope of manufacturing, from mops and buckets to robots and automation. Laura has been a manufacturing product writer for eight years, knowledgeable about the ins and outs of the industry, along with what readers are looking for when wanting to learn about the latest products on the market.