Today tracking data is highly valued. It can help the production flow, maintenance, and business decisions. With online platforms it can be easy to track, but how many companies really take advantage of the information. One company pushing for more data is 3D Hubs. They shared their second-quarter report with Machine Design and the data offers an insight on the highest rated and most used 3D printers both industrial and desktop. The following is from the Digital Manufacturing Trends Q2/2018 report that looked at 6,000 active suppliers who create more than 200,000 parts each quarter.

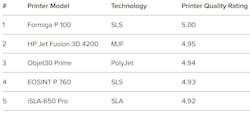

The report is based on the top 10 rated industrial printers out of 200 printer models listed on 3D Hubs, based on print quality ratings from customer review data. Only printers with more than 30 reviews in the quarter are included in these statistics.

Industrial

Formiga P 100 SLS printer scores a perfect 5.00 every quarter since the start of 2017. The SLS machine creates parts with a minimum layer height of 60 microns and a build volume = 200 x 250 x 330 mm (about 7.9 x 9.8 x 13 inches).

The HP’s Jet Fusion 3D 4200 machine has jumped from #8 to #2 moving from a 4.75 rating to a 4.95, the MJF technology machine is useful for short-run manufacturing needs thanks to the speed of the process. Moving from #10 in Q1 to #3 is the Objet30 Prime, a PolyJet machine that allows you to combine materials with different properties to create the visual representation of the end product.

The technology spread of the Top 10 has remained the same since Q2 with 60% of the machines using selective laser sintering (SLS) technology. Stereolithography (SLA) has doubled its presence with the Ipro 9000 a new entrant into the top 10 at the ninth position. The top 5 printers are listed here but for a complete listing click on the full report here.

The top four most used printers are making nearly 10,000 prints compared to 2,562 by the rest of the Top 10. The HP Jet Fusion 3D 4200 takes #1 spot for the second quarter running, doubling its total output from 2,437 prints in Q1 to 5,087 in Q2. The Formiga P 110 maintained second place adding 50% to the total from 1,695 to 2,796. The SPro 230 in #3 maintained its performance with just over 1,000 prints.

The top four used shows its dominance in the industry thanks to it offering very high design freedom, high accuracy and parts with good and consistent mechanical properties.

Desktop

Another quarter, another desktop printer tops the print quality ratings. The Ultimaker 2+ moves from #2 to #1. Although the Ultimaker 2+ was launched back in 2016 it has become a respected workhorse in its field with a rating of 4.86.

Prusa Research sees three machines in the Top 10 with the MK2S taking #2, MK2 at #4 and the new MK3 continuing its respected pedigree at #7. What’s even more impressive is that the MK2 sits at #4 with the most reviews of all the machines featured. Ultimaker has matched the feat with the 2+, 2 and 3 all making the top 10, showing 2 manufacturers increasing their market share. That being said, the Form 2 remains the only SLA machine to be featured in the Top 10 since 2017.

It should be noted that the while the rating of the top-ranked printer is close, almost 0.1 difference between #1 to #10, the prices differ greatly. Ultimaker and Form 2 can cost thousands (around $2,500 to $3,000 respectively), while the Original Prusa i3 MK2 and 2S are sold in do-it-yourself kits from just a few hundred dollars.

For the most used desktop printers, the top 10 went from 57,516 to 67,516 with all machines seeing an increase. The most used desktop printer in Q2 was the Original Prusa i3 MK2, no surprise as the most reviewed machine, producing 15,087 parts. Following closely at #2 is the Form 2, thanks to its ability to create prints with a smooth surface finish and with high accuracy. The Flashforge Creator Pro maintained its position at third spot creating 33% more prints than in Q1.

A surprise entrant is the Fusion3 F400-S, an industrial desktop FDM machine that can print in all manner of thermo-plastics available on the market. It placed #9 with a respectable 3,444 prints made.

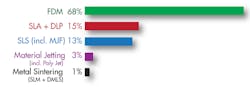

The technology overall is dominated by extruded plastics know as fused deposition modeling (FDM) or fused filament fabrication (FFF) with 68% market share of 3D Hubs business. This may be that extruding plastic is still the most affordable way to get the first prototype in your hands. FDM saw a marginal increase of 2% whilst SLA + DLP maintained a 15% share at #2. SLS is at #3 and saw an increase in popularity with a small 1% bump to 13%. SLS is continuing its chase of SLA + DLP as the gap may close even further as we see SLS dominate the most popular industrial technologies.

Data like this can be easily tracked with 3D Hubs online portal. While this is only one company many of these names continuously appear in many of the factories I’ve visited: Stratasys, eos, Formlabs, Ultimaker, etc. 3D Hubs was founded by Bram De Zwart at a time when 3D Systems was looking to put a 3D printer in every home. However, Bram discovered that most 3D printer owners only use their printers on occasion and that 95% of the time the printer just sits around. He saw an opportunity to bring manufacturing much closer to the end-user, which is the real promise of 3D printing. Today this platform represents over 200,000 parts being printed every quarter. In addition, 3D Hubs seems non-bias resource for reviews and data as they connect customers with printers and aren’t trying to sell any specific brand. This data might not tell you which the best printer is, but it might let you know what the industry is using thus providing a place to start if you are looking at printers.

About the Author

Jeff Kerns

Technology Editor, Machine Design

Studying mechanical engineering at Rochester Institute of Technology (RIT), Jeff Kerns worked in the Polymer Research Lab. Using RIT’s co-op program, he worked for two aerospace companies focusing on drafting, quality, and manufacturing for aerospace fasteners and metallurgy. He also studied abroad living in Dubrovnik, Croatia.

After college, he became a commissioning engineer, traveling the world working on precision rotary equipment. Then he attended a few master's courses at the local college and helped an automation company build equipment.

Growing up in Lancaster County, PA he always liked to tinker, build, and invent. He is ecstatic to be at Machine Design Magazine in New York City and looks forward to producing valuable information in the mechanical industry.