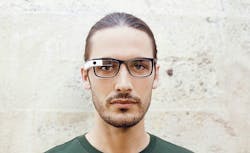

To improve their efficiency and narrative flow, editors often recommend writers "kill their darlings," meaning cut the fluff and flair, and get to the damn point. You could say this rule applies as much to crafting industrial tools and as it does prose, and it's a lesson Alphabet seems to have learned with Google Glass Enterprise Edition.

With peak interest and visibility at its launch in 2013, Glass Explorer Edition was poised to revolutionize wearables the way the Google redefined search engines — and pretty much the whole Internet. After a buggy, bumpy de facto Beta that publicly highlighted Glass's flaws, Explorer's run unceremoniously ended in 2015.

The Google X project had cracks, to be sure, such as a puny battery, but the core wasn't broken. All the critical features—from the monocular display to run work instructions to the camera to stream video or take pictures—were there at the inception.

It was a fine first draft. Even Hemingway would flinch at releasing an early work into the world, and the stampede of criticism now seems a bit overblown, a mob version of darling-killing.

As the unflattering first impression faded away, the biggest names in manufacturing, including GE and Boeing, were quietly running pilot programs with a revamped version, paring the hardware with Skylight, the enterprise wearable solution made by Upskill, one of a dozen Glass partners from whom you can order the new edition.

Boeing found that reading work instructions on Glass as opposed to fumbling with manuals cut the time to assemble intricate wire harnesses by 25%, with nearly zero errors.

GE, meanwhile, has deployed Glass in several segments, including GE Aviation, which has the most to gain from even the slightest of incremental improvements. If the mechanics at the Cincinnati facility are off on torque values when tightening B-nuts to seal critical jet engine fluid lines and hoses, the results could be disastrous.

"With fuel and oil fittings, if you don't get that just right, there are opportunities for leaks," says Ted Robertson, engineering manager at GE Aviation. "And you can imagine where a fuel leak could end up going."

He says over or under-torqueing could lead to costly teardowns and missed time on the testing platform, or even more expensive repercussions if the engine makes it closer to the runway. To ensure the most precise and accurate measurement, Glass was linked with Skylight and a Bluetooth-enabled torque wrench.

In the morning, fifteen senior mechanics first created a baseline by using paper instructions to perform maintenance on a CF34-8C engine, which they had no experience with prior. Then after lunch, those mechanics each received individual instruction on how to use Glass and Skylight for 30-45 minutes and completed the same task.

Download the case study here.

The result was an average of 8 to 11% efficiency improvement, with one mechanic cutting time by 25% on one task. And GE had evidence each b-nut was within the 132-150 in./lb. range, as the work instructions would not proceed until that requirement was met.

"We think it would only get better from where we started from," Robertson says.

The Glass camera, which came under fire for infringing on privacy, here was used to take historical pictures for quality assurance. The video could also be streamed to a remote expert for troubleshooting out of the work instruction's purview.

"Easily, millions of dollars can be saved improving our processes with this," Robertson says.

In a survey following the test, 85% agreed to the statements: "I believe that using this system will reduce manufacturing errors," and "I thought the system was easy to use."

Those are the two critical objectives Upskill targets: making work more efficient and easier. Compressing a giant manual into a miniature screen certainly does that.

"People can really be focused on what they do really well rather than trying to memorize stuff out of a manual," says Upskill CEO Brian Ballard.

Robertson says Glass first competed against Vuzix Smart Glasses and Intel's Recon Jet Pro prior to being selected as the case study's hardware. The mechanics spent hours with each before picking their favorite.

"They thought Google Glass was the easiest to swipe with and select, comfortable, and easiest to adjust [TH4] the display position," Robertson says.

All those Glass-half-empty reviewers actually helped turn the wearable fit for duty. This version is clearly meant to impress engineers and technicians whose ultimate goal is completing tasks quickly and correctly, unlike the consumer-facing edition marketed for fictional bourgeois hipsters.

"Right off the bat, you have a generational improvement in all of the sub-components of Glass," says Ballard. "The battery is larger, the processor is more efficient."

This battery should last an eight-hour shift, less the more video is used, and the ergonomics have been vastly improved as well.

Another big change is that you can fold this pair and put it in your pocket.

"You'd think that to be a minor thing, but it has a lot of impact in usability," Ballard says.

Real world testing also led designers to make the electronic portion detachable, so a user can affix it to prescription lenses or safety glasses.

Google wisely didn’t mess with what did work, though.

"There are a couple things that are very familiar: the touch-swipe user paradigm, the voice control is very accurate, and the optics are comfortably placed," Ballard says.

Since Google exiled its product to stealth mode, it faces a daunting challenge similar to Daenerys Targaryen's return to Westeros on Game of Thrones. It's a landscape rife with competitors great and small, with some rising as others fall. As promising startup RealWear introduces the voice-driven HMT-1, Intel sacrificed its whole wearable division, including the Recon Jet Pro.

With unparalleled name recognition, big name testimony, and redemption at stake, this version of Glass should not flame out any time soon.

The real winner may be companies like Upskill, who program the software pushing the devices' functionality to their limits.

"Our goal is to drop the frustration level of information access to zero for the workforce," says Ballard, who adds that like any tool, the more you use wearable computers, the more proficient you'll get ."And we can continue to add abilities, like better AI assistance, so you keep getting significant year over year increases."

GE currently is studying the results of the case study, along with several other similar pilot programs across its vast empire to understand this new human-machine interface.

We all know wearables are coming, but GE is being more patient than the early Glass explorers.

"Changing to a new way takes time, some convincing, and money," Robertson says. "That's what we're trying to put together right now."

And Ballard's ballad continues, singing the praises of wearables in general, and Google Glass in particular.

"The real story here is companies have a serious opportunity to employ this wearable technology in a way they've known about for years, and they're finally now able to confidently adopt it, reliably and repetitively show the benefits of the workforce," he says. "That's the natural evolution of any technology."

About the Author

John Hitch

Editor, Fleet Maintenance

John Hitch, based out of Cleveland, Ohio, is the editor of Fleet Maintenance, a B2B magazine that addresses the service needs for all commercial vehicle makes and models (Classes 1-8), ranging from shop management strategies to the latest tools to enhance uptime.

He previously wrote about equipment and fleet operations and management for FleetOwner, and prior to that, manufacturing and advanced technology for IndustryWeek and New Equipment Digest. He is an award-winning journalist and former sonar technician aboard a nuclear-powered submarine where he served honorably aboard the fast-attack submarine USS Oklahoma City (SSN-723).